Efficient heavy oil stain cleaning agent, preparation method thereof and heavy oil stain cleaning method

A heavy oil stain cleaning agent and heavy oil stain technology, applied in the field of oil stain cleaning agents, can solve the problems of unsatisfactory cleaning effect of cleaning agents, confusion in precision component processing, and increased equipment costs, etc., to achieve good biodegradability and low phosphorus content , fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

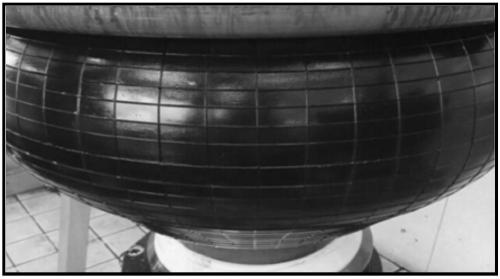

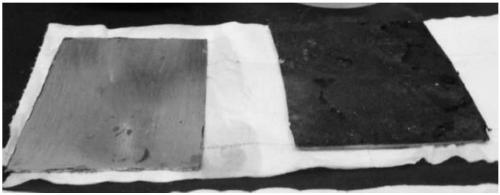

Image

Examples

Embodiment 1

[0037] This embodiment provides a high-efficiency heavy oil stain cleaning agent. In terms of weight percentage, the raw material composition of the high-efficiency heavy oil stain cleaning agent includes: potassium phosphate 1.5%, sodium lauryl polyoxyethylene ether sulfate 2%, ethylenediaminetetraacetic acid 2.35% of tetrasodium, 0.4% of diethanolamine, 0.2% of urotropine, 0.2% of polyether defoamer, 4% of isopropanol, and the balance of water, the sum of the contents of each raw material is 100%.

[0038] The high-efficiency heavy oil stain cleaning agent of this embodiment can be obtained by mixing and stirring the above raw materials evenly.

Embodiment 2

[0040] This embodiment provides a high-efficiency heavy oil stain cleaning agent. In terms of weight percentage, the raw material composition of the high-efficiency heavy oil stain cleaning agent includes: sodium pyrophosphate 1.5%, cetyl alcohol polyoxyethylene ether 7%, sodium citrate 2.35%, triethanolamine 1.75%, benzotriazole 0.2%, organosilicon defoamer 0.2%, ethylene glycol ether 4%, water balance, the sum of the content of each raw material composition is 100%.

[0041] The high-efficiency heavy oil stain cleaning agent of this embodiment can be obtained by mixing and stirring the above raw materials evenly.

Embodiment 3

[0043]This embodiment provides a high-efficiency heavy oil stain cleaning agent. In terms of weight percentage, the raw material composition of the high-efficiency heavy oil stain cleaning agent includes: sodium tripolyphosphate 1.5%, sodium dodecylbenzene sulfonate 2%, sodium citrate 2.35%, diethanolamine 0.4%, organophosphate SD-10 0.2%, organosilicon defoamer 0.2%, ethylene glycol monobutyl ether 4%, water balance, the sum of the content of each raw material composition is 100%.

[0044] The high-efficiency heavy oil stain cleaning agent of this embodiment can be obtained by mixing and stirring the above raw materials evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com