Comb-like polyfarnesene rubber and preparation method thereof

A technology of polyfarnesene and farnesene, which is applied in the field of polyfarnesene rubber with comb-like structure and its preparation, can solve the problems of harsh process condition control, low catalytic efficiency, easy deactivation and the like, and achieves flexural resistance. Excellent fatigue performance, high catalytic efficiency, good grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

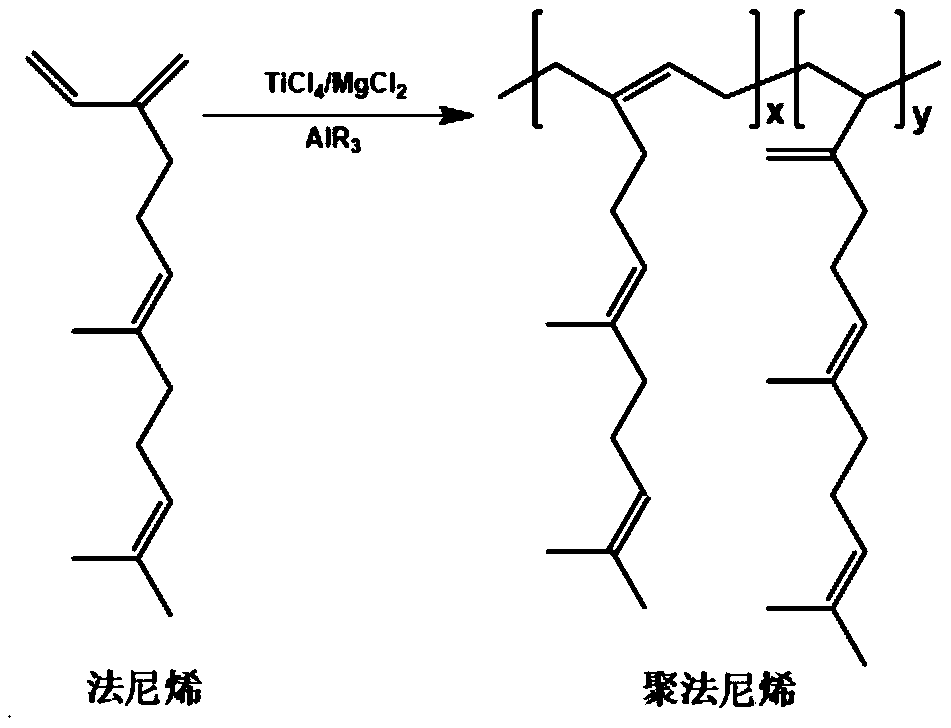

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a polyfarnesene rubber, which is prepared by the following method: under nitrogen protection, 750 mL of farnesene monomer is added to the reactor, followed by adding 1.2 mL of triisobutyl Aluminum and 0.4 g anhydrous magnesium chloride loaded with 2% TiCl 4 The Ziegler-Natta catalyst is used, and the reaction pressure in the reactor is adjusted to be 0.2MPa. The polymerization reaction temperature was 60°C, and the polymerization reaction was 6 hours. After the polymerization was completed, acidified ethanol was added to terminate the polymerization reaction, and vacuum-dried at 90°C to obtain about 168 grams of colorless to light yellow transparent polyfarnesene rubber material.

[0033] In this reaction, the catalytic efficiency of the product is 3500 / g.Ti.h, and the obtained polyfarnesene rubber homopolymer has a weight-average molecular weight Mw of about 115861, and the sample is named PFR1.

Embodiment 2

[0035] This embodiment provides a polyfarnesene rubber, which is prepared by the following method: under nitrogen protection, 750 mL of farnesene monomer is added to the reactor, followed by adding 1.2 mL of triisobutyl Aluminum and 0.4 g anhydrous magnesium chloride loaded with 2% TiCl 4The Ziegler-Natta catalyst is used, and the reaction pressure in the reactor is adjusted to be 0.2MPa. The polymerization reaction temperature is 60°C, and the polymerization reaction is 6 hours. During the polymerization reaction, hydrogen gas is added once every two hours. The partial pressure of hydrogen gas is 0.005, and a total of three times are added at 0h, 2h, and 4h respectively. First, nitrogen is used to adjust the reaction The reaction pressure of the reactor was 0.02 and then 0.005 partial pressure was supplemented with hydrogen. After the polymerization was completed, acidified ethanol was added to terminate the polymerization reaction, and vacuum-dried at 90° C. to obtain about...

Embodiment 3

[0038] This embodiment provides a polyfarnesene rubber, which is prepared by the following method: under nitrogen protection, 750 mL of farnesene monomer is added to the reactor, followed by adding 1.2 mL of triisobutyl Aluminum and 0.4 g anhydrous magnesium chloride loaded with 2% TiCl 4 The Ziegler-Natta catalyst is used, and the reaction pressure in the reactor is adjusted to be 0.2MPa. The polymerization reaction temperature is 60°C, and the polymerization reaction is 6 hours. During the polymerization reaction, hydrogen is added every 1 hour, and the partial pressure of hydrogen is 0.005. A total of three times are added at 0h, 1h, 2h, 3h, 4h, and 5h. , first use nitrogen to adjust the reaction pressure of the reactor to 0.02 and then use hydrogen to supplement 0.005 partial pressure. After the polymerization was completed, acidified ethanol was added to terminate the polymerization reaction, and vacuum-dried at 90° C. to obtain about 208 grams of colorless to light yell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com