Titanium dioxide for decorative paper and preparation method

A technology for titanium dioxide and decorative paper, applied in the field of titanium dioxide, can solve the problems of low papermaking retention rate, low isoelectric point, affecting product color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

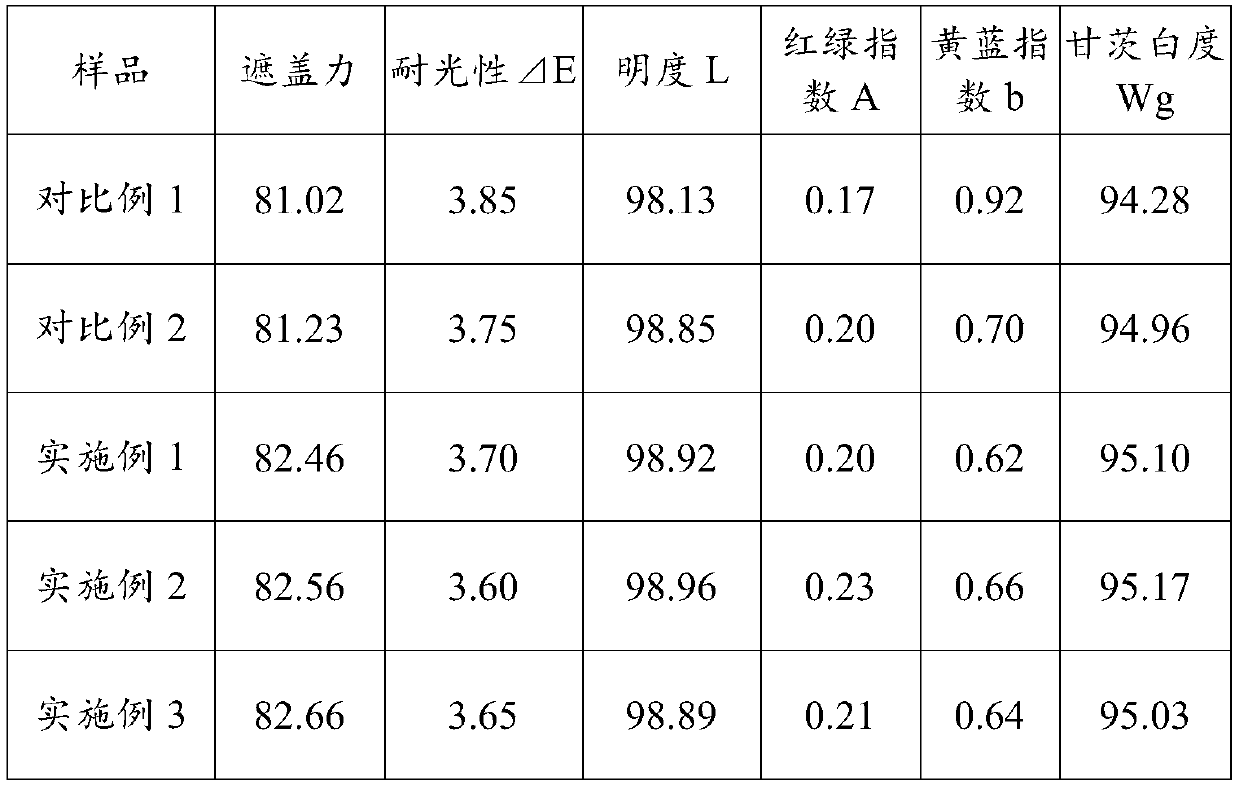

Embodiment 1

[0048] The abrasive slurry is imported into the coating tank, and the control slurry concentration is 350g / L (in the form of TiO 2 At the same time, the temperature was raised to 80°C; 2.8% of the mass fraction of titanium dioxide in the slurry was added within 60 minutes. 4 P 2 o 7 solution, 0.8% TiOCl 2 Solution and 0.6% sodium aluminate solution, control pH=4.5~5.5, homogenize for 30min; adjust the pH=9.5 of the slurry with dilute NaOH solution, adjust for 30min, homogenize for 30min; add titanium dioxide mass fraction in the slurry within 120min 2.5% NaAlO 2 solution, 1.0% MgSO 4 solution and H 2 SO 4 Solution, maintain co-current pH = 9.5, homogenize for 30min; use dilute H 2 SO 4 Adjust pH=7.0, adjust for 30 minutes, homogenize for 120 minutes; wash with water, flash evaporate, steam powder to obtain the product.

Embodiment 2

[0050] The abrasive slurry is imported into the coating tank, and the control slurry concentration is 350g / L (in the form of TiO 2 At the same time, the temperature was raised to 80°C; 2.0% of the mass fraction of titanium dioxide in the slurry was added within 60 minutes. 4 P 2 o 7 solution, 0.6% TiOCl 2 Solution and 0.4% sodium aluminate solution, control pH=4.5~5.5, homogenize for 30min; adjust the pH=9.5 of the slurry with dilute NaOH solution, adjust for 30min, homogenize for 30min; add titanium dioxide mass fraction in the slurry within 100min 3.0% NaAlO 2 solution, 0.8% MgSO 4 solution and H 2 SO 4 Solution, maintain co-current pH = 9.5, homogenize for 30min; use dilute H 2 SO 4 Adjust pH=7.0, adjust for 30 minutes, and homogenize for 120 minutes; wash with water, flash steam, and steam powder to obtain the product, and the others are the same as in Example 1.

Embodiment 3

[0052] The abrasive slurry is imported into the coating tank, and the control slurry concentration is 350g / L (in the form of TiO 2 At the same time, the temperature was raised to 80°C; 1.2% of the mass fraction of titanium dioxide in the slurry was added within 60 minutes. 2 HPO 4 solution (in P 2 o 5 meter, solution concentration is 90g / L), 0.4% TiOCl 2 solution (with TiO 2 meter, solution concentration 120g / L) and 0.23% sodium aluminate solution (as Al 2 o 3 solution concentration 140g / L), control pH=4.5~5.5, homogenize for 30min; use dilute NaOH solution (solution concentration 240g / L) to adjust the pH of the slurry=9.5, adjust for 30min, homogenize for 30min; The mass fraction of titanium dioxide in the slurry is 3.5% NaAlO 2 solution (as Al 2 o 3 meter, solution concentration 140g / L), 0.5% MgSO 4 Solution (as MgO, solution concentration 140g / L) and dilute H 2 SO 4 Solution (solution concentration 240g / L), maintain co-current pH=9.5, homogenize for 30min; use d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com