Surface metallization method for composite dielectric substrate of printed circuit

A composite medium and substrate surface technology, which is applied in the direction of printed circuit, improvement of metal adhesion of insulating substrate, printed circuit manufacturing, etc., can solve problems such as missing plating, plating layer falling off, etc., to speed up deposition, increase surface roughness, enhance The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

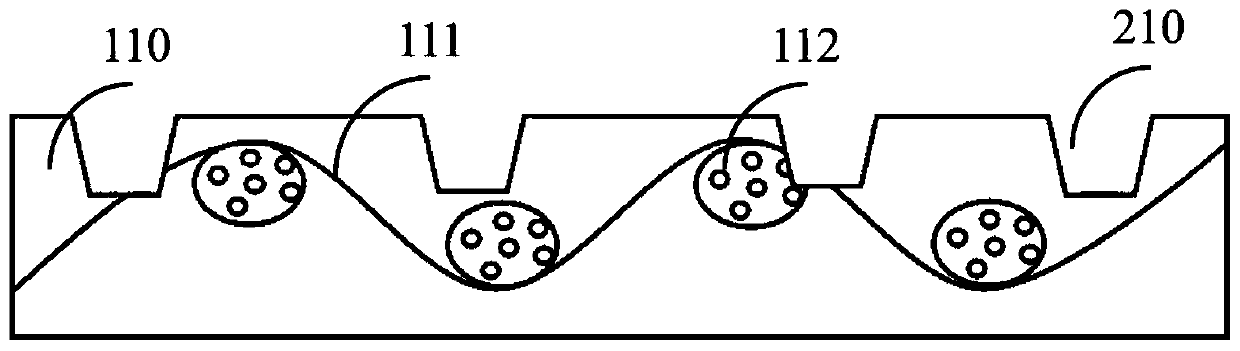

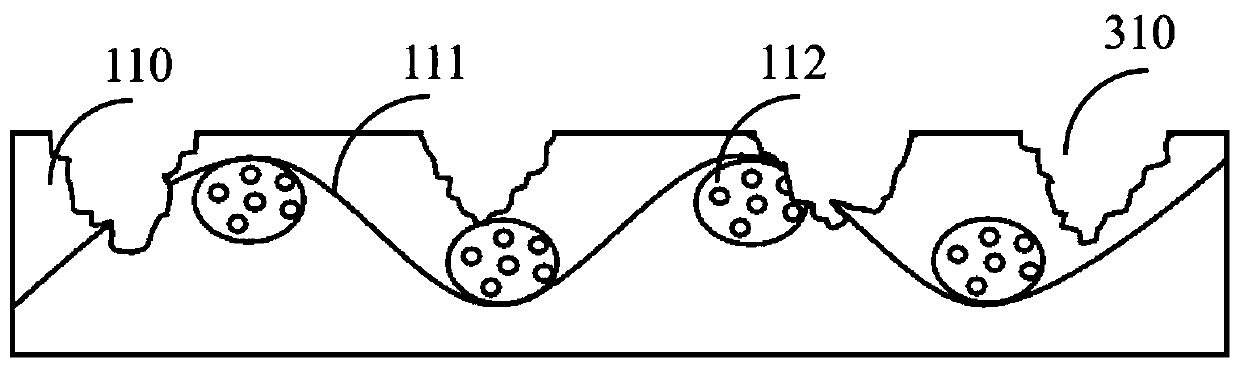

[0038] Step 1. Form a plurality of densely packed holes (210) with a depth of 2 μm and a diameter of 100 μm arranged in an array on the surface of the carbon fiber / cyanate composite dielectric substrate by laser drilling, wherein the spacing between adjacent holes is 80 μm. The laser energy is 0.4mJ, and the pulse width is 2μs; the 2D and 3D roughness images of the carbon fiber / cyanate composite dielectric substrate exposed resin and fiber cloth after laser ablation in step 1 are as follows Figure 6 As shown in (c) and 6(d), it shows that laser ablation forms dense holes on the surface of the dielectric substrate, which increases the surface roughness and is conducive to the formation of a riveting structure between the metal coating and the dielectric substrate;

[0039] Step 2, performing low-temperature plasma roughening on the composite dielectric substrate treated in step 1, specifically: placing the composite dielectric substrate at 80% O 2 and 20% CF 4 (volume percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com