Benzodiazepine compound topical pharmaceutical composition and preparation method and use

A composition and compound technology, applied in the direction of drug combination, pharmaceutical formula, medical preparations of non-active ingredients, etc., can solve the problems of inconvenient injection of preparations, high cost of industrial production, inconvenient medication for patients, etc., to achieve convenient self-management , Guaranteed drug efficacy, avoiding the effect of hepatic first-pass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 Compound (R) represented by formula (I) 1 is methyl, R 2 Preparation of transdermal patch for methyl)benzenesulfonate

[0076] (1) Compound (R) represented by formula (I) 1 is methyl, R 2 Be methyl) benzene sulfonate 8g and Soluplus7.4g, magnesium stearate 0.5g micronization, add polyethylene glycol (molecular weight 2000) 14g, mix well, make physical mixture;

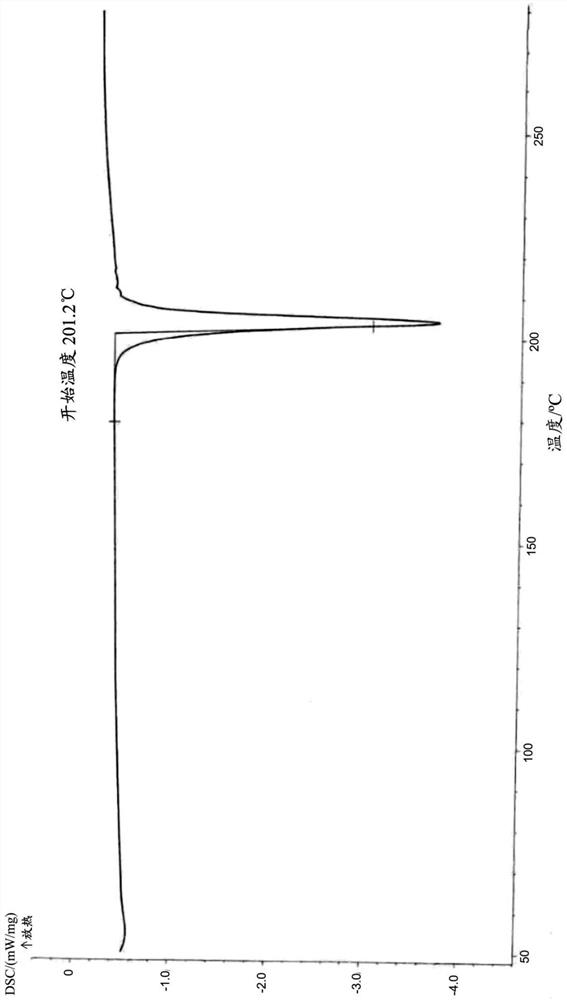

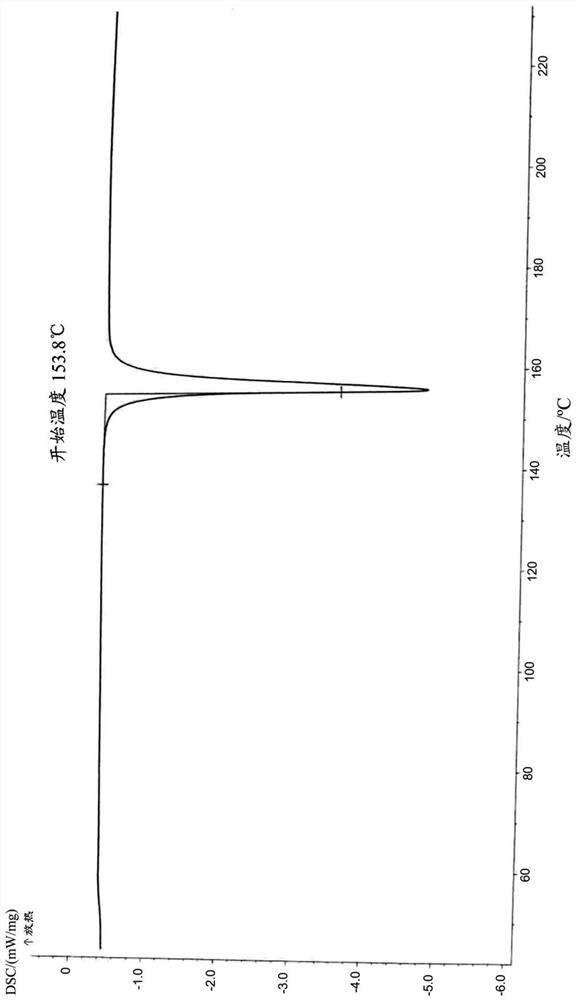

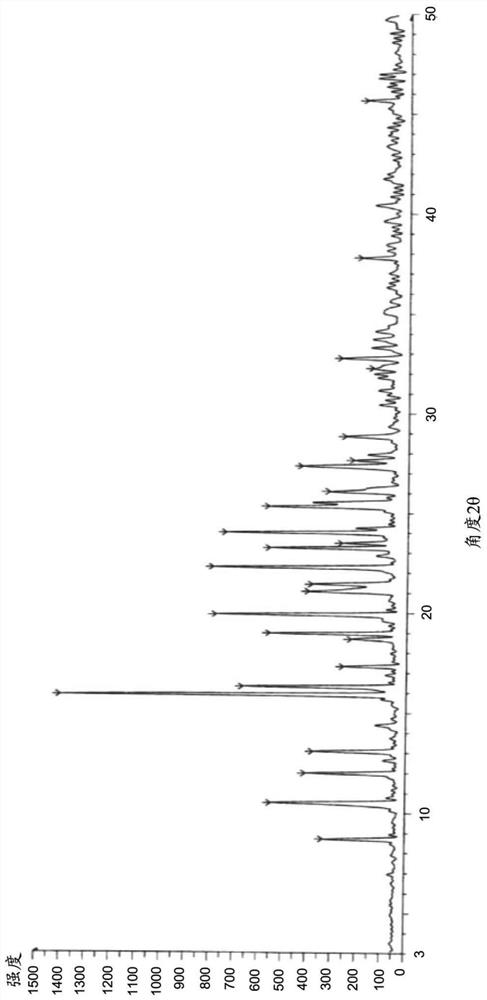

[0077] (2) Set the extrusion temperature of the twin-screw extruder to be 120°C, start the screw after rising to the set temperature, add the physical mixture in the step (1) to the extruder, and then heat-melt and extrude, It is extruded into spherical particles to obtain amorphous particles, which are then micronized to obtain micronized amorphous particles, and the particle size is controlled at about 100-150 nm.

[0078] (3) Weigh 3 g of micronized amorphous particles prepared in step (2), 2 g of soybean lecithin, 0.3 g of cholesterol, 30 g of dehydrated alcohol, and 64.7 g of water;

[0079] ...

Embodiment 2

[0086] Embodiment 2 Compound (R) represented by formula (I) 1 is methyl, R 2 Preparation of transdermal patch for ethyl)

[0087] (1) Compound (R) represented by formula (I) 1 is methyl, R 2 For ethyl) 0.9g and povidone (PVP-S630) 3.1g, talc 0.2g micronized, add polyethylene glycol (molecular weight 4000) 5.8g, mix uniformly to obtain a physical mixture;

[0088] (2) Set the extrusion temperature of the twin-screw extruder to be 120°C, start the screw after rising to the set temperature, add the physical mixture in the step (1) to the extruder, and then heat-melt and extrude, It is extruded into spherical particles to obtain amorphous particles, which are then micronized to obtain micronized amorphous particles, and the particle size is controlled at about 150-175 nm.

[0089] (3) Weighing the compound (R) represented by the formula (I) prepared in step (2) 1 is methyl, R 2 ethyl) micronized amorphous particles 0.3g, phosphatidylcholine 2g, cholesterol 0.3g, propylene gl...

Embodiment 3

[0097] Embodiment 3 Compound (R) represented by formula (I) 1 for hydrogen, R 2 Preparation of transdermal patch for methyl)

[0098] (1) Compound (R) represented by formula (I) 1 for hydrogen, R 2 Be methyl) 0.8g and povidone (PVP-K30) 3g, magnesium stearate 0.2g micronize, add polyethylene glycol (molecular weight 6000) 6.0g, mix well, make physical mixture;

[0099] (2) Set the extrusion temperature of the twin-screw extruder to be 120°C, start the screw after rising to the set temperature, add the physical mixture in the step (1) to the extruder, and then heat-melt and extrude, It is extruded into spherical particles to obtain amorphous particles, which are then micronized to obtain micronized amorphous particles, and the particle size is controlled at about 180-230 nm.

[0100] (3) Weighing the compound (R) represented by the formula (I) prepared in step (2) 1 for hydrogen, R 2 For methyl) micronized amorphous particles 7g, phosphatidylethanolamine 2g, cholesterol 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com