Numerical control machine tool cutter state monitoring and control system and method

A technology of CNC machine tools and control methods, which is applied in general control systems, control/regulation systems, computer control and other directions, can solve the problems of misjudgment of tool status, reduced stability, low adaptability and accuracy, etc. High accuracy and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

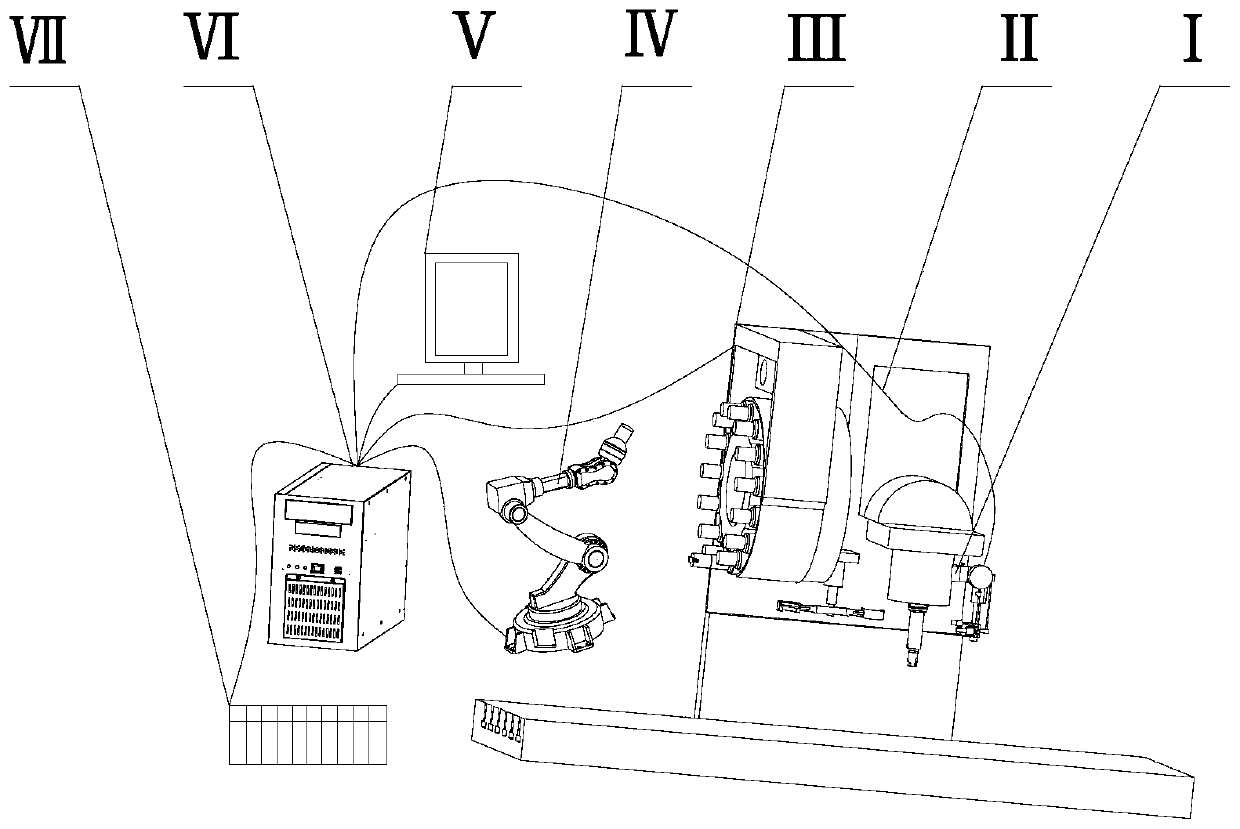

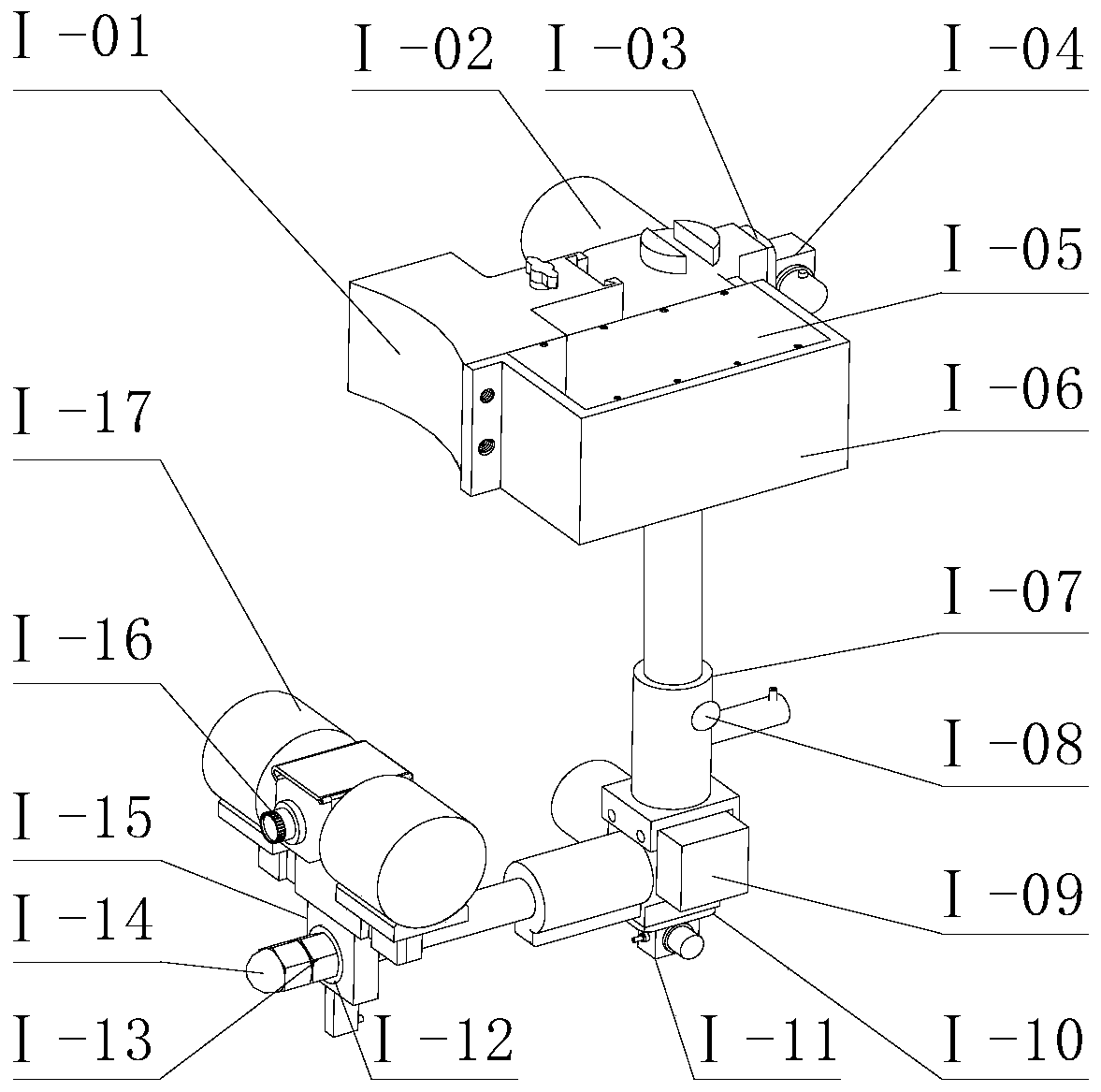

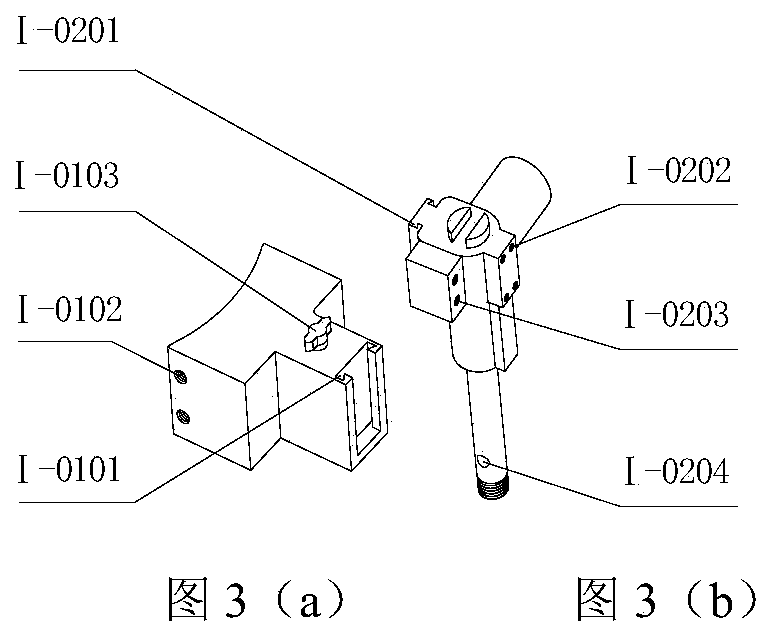

[0118] See attached figure 1 As shown, this embodiment discloses a CNC machine tool tool state monitoring and control system, including data acquisition unit Ⅰ, data analysis and processing unit Ⅱ, database unit Ⅶ, decision-making and control unit Ⅵ, intelligent tool magazine unit Ⅲ, display unit Ⅴ and abnormal Tool delivery unit Ⅳ. The system can realize accurate judgment of tool status through data acquisition and data analysis and processing unit. The intelligent tool magazine unit and decision-making and control unit realize the replacement of new tools when the machine tool is abnormal, the accurate judgment and classification of abnormal tools, and subsequent intelligent processing.

[0119] In an implementation example, Figure 23 It is a schematic diagram of the connection of each unit of the system; the data acquisition unit includes a power sensor, a data acquisition card, an industrial CCD camera and an AD converter, completes the data acquisition and transmits it ...

Embodiment 2

[0178] This implementation example discloses a CNC machine tool tool state monitoring and control method, Figure 24 It is the working flow chart of the machine tool after the initial judgment of tool abnormality; Figure 25 It is a schematic diagram of the wear of the replaceable tool blade; Figure 27 It is the schematic diagram of the tool initial judgment module; including:

[0179] The data acquisition unit and the data analysis and processing unit are divided into two subsystems, which are used for pre-judgment and accurate judgment of the tool state respectively.

[0180] The way to realize the pre-judgment of the tool state is as follows:

[0181] Through the vibration sensor inside the intelligent tool holder, the vibration signal during the machining process is detected and used as the signal input for the system tool detection pre-judgment.

[0182] The vibration sensor is integrated inside the intelligent tool handle and uses wireless transmission inside the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com