Stable dispersing agent and application in preparation of copolymer polyol

A technology of copolymer polyol and stabilizing dispersant, which is applied in the field of copolymer polyol preparation, can solve the problems of high viscosity, low solid content of copolymer polyol, large amount of stabilizer dispersant, etc., and achieves low viscosity and easy operation. , The effect of good stability and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

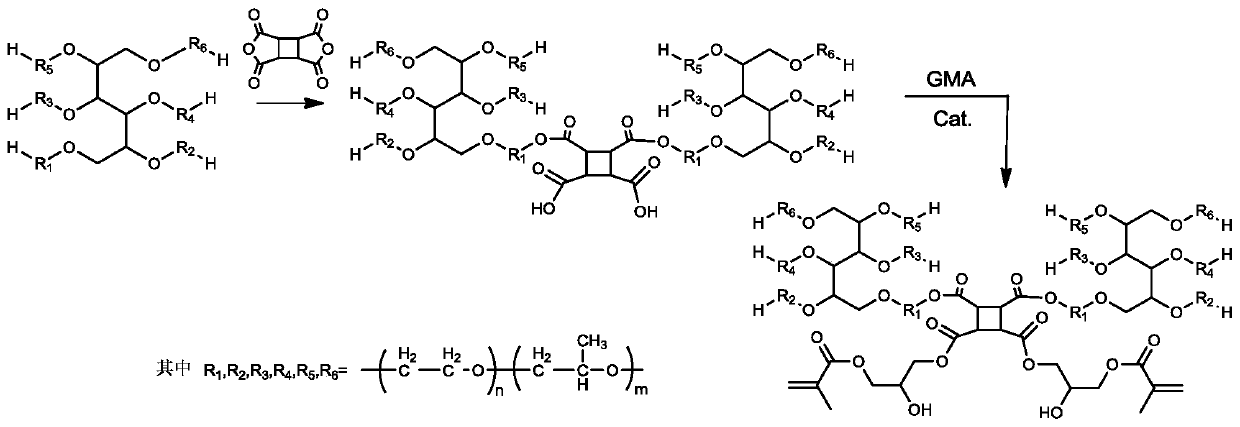

[0056] The preparation of stable dispersant 1 (reaction schematic diagram can refer to figure 2 ):

[0057] Mix 3000 g of polyether polyol A, 40.3 g of cyclobutane tetracarboxylic dianhydride, and 180 g of acetone evenly, raise the temperature to 100° C., and stir and reflux for 16 hours. Then, add 3.1g of ethyltriphenylphosphine iodide and stir to dissolve, then add 40.3g of glycidyl methacrylate (GMA) and 1.78g of hydroquinone, react overnight at 120°C, and the resulting product is transparent Light yellow liquid, viscosity is 2580mPa.s, degree of unsaturation is

[0058] 0.076meq / g, has a higher degree of unsaturation than the contrast stabilizer, indicating that it has more active sites.

Embodiment 2

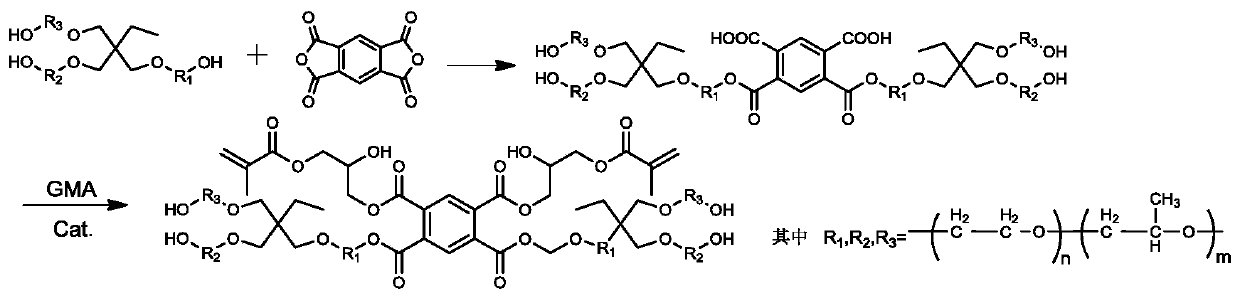

[0060] The preparation of stable dispersant 2 (reaction schematic diagram can refer to figure 2 ):

[0061] Mix 3000 g of polyether polyol B and 41.9 g of pyromellitic dianhydride evenly, heat to 120° C., and react for 18 hours under nitrogen protection. Then add 3.0g of ethyltriphenylphosphine iodide (ETPPI) and stir to dissolve, then add 36.1g of glycidyl acrylate (GA) and 0.90g of hydroquinone, and react overnight at 120°C. The resulting product is a transparent light Yellow liquid with a viscosity of 1780mPa.s and a degree of unsaturation of 0.092meq / g, which has a higher degree of unsaturation than the comparison stabilizer, indicating that it has more active sites.

Embodiment 3

[0063] Copolymer polyol 1 preparation:

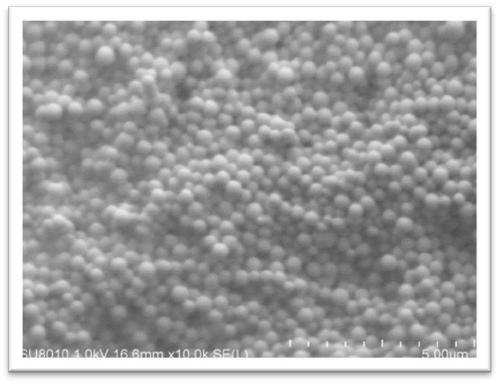

[0064] The 500ml four-necked bottle is equipped with a stirrer, a heating device, a temperature control device and a feeder as a reactor. Add 55.4g of basic polyether polyol (Wanhua 3156), 3.6g of stable dispersant 1, after nitrogen replacement, stirring and slowly raising the temperature to 110°C, and continuously adding topping materials (10.47g of isopropanol, 85.71g of basic polyether polyol 3156, a mixture of 46.55g of acrylonitrile, 69.83g of styrene, and 1.21g of azobisisobutyronitrile), and the temperature is controlled at 115°C to 120°C. The dropwise addition was completed within 100 minutes, the feeding was completed, the aging reaction was carried out for 1 hour, the temperature was raised to 160°C, and the unreacted monomer was removed in vacuum for 2 hours to obtain the product, and the product index was measured. Residual styrene / acrylonitrile / isopropanol are respectively 2 / 2 / 4ppm in sequence, hydroxyl value is 29.8mgK...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com