A kind of diaphragm lithiation method and lithiated diaphragm

A lithiation and diaphragm technology, applied in the direction of separators/films/diaphragms/spacers, structural parts, electrical components, etc., can solve the problems of uneven lithium dispersion and the formation of dendrites on the surface of the diaphragm, to promote uniformity, The effect of improving lithiation efficiency and improving the uniformity of solution dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] S1. Take 3.0842g of biphenyl and put it into a wide-mouthed bottle, then put the wide-mouthed bottle into a vacuumed glove box for subsequent operations, take 40 mL of anhydrous tetrahydrofuran and pour it into the wide-mouthed bottle, and then add 0.2832g Lithium-magnesium alloy, stir until the alloy no longer dissolves, and then stand for 0.5h to obtain a dispersed lithiation solution.

[0060] S2. Put the Zif-8 coated diaphragm (the polymer matrix is PE-PP-PE composite diaphragm, the total thickness is 25 μm, and the thickness of the three layers is equal; the coating thickness is 3 μm) into the lithiation solution, soaked for 3 hours, and taken out , washed with tetrahydrofuran until the surface of the separator was colorless, and air-dried to obtain a lithiated separator. The preparation of the above-mentioned lithiation solution and the immersion of the separator were carried out at room temperature (21° C.).

Embodiment 2

[0064] SEM, TEM characterization:

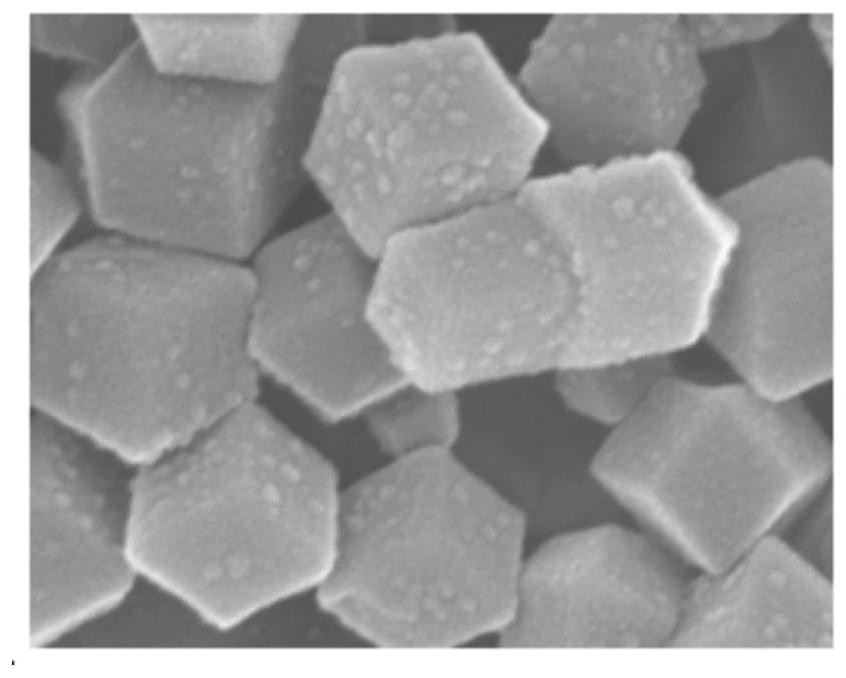

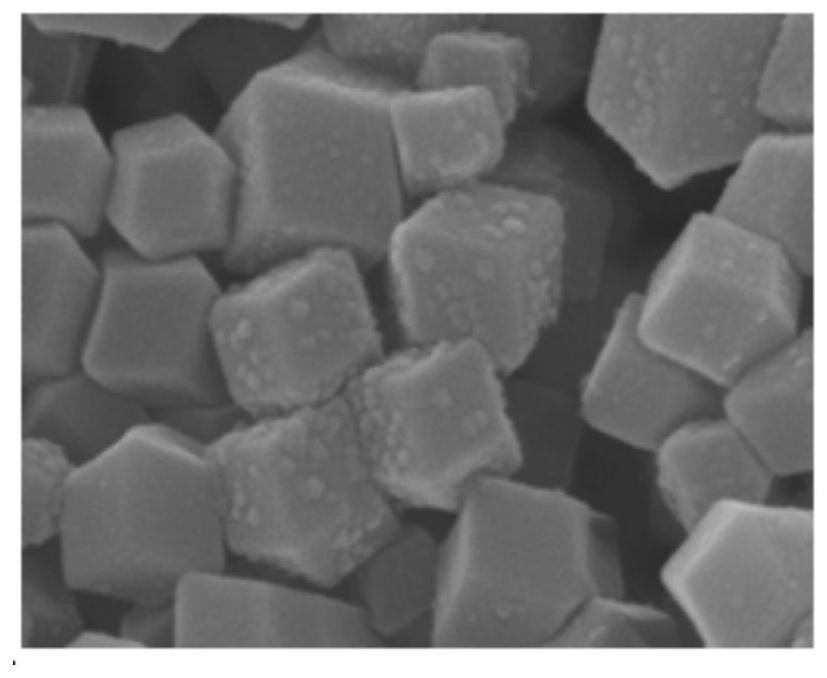

[0065] The lithiated diaphragms obtained in Example 1 and Comparative Example 1 were respectively subjected to scanning electron microscopy tests, and the results were shown in figure 1 and figure 2 ; figure 1 is the SEM image of the lithiated separator obtained in Example 1, figure 2 It is the SEM image of the lithiated separator obtained in Comparative Example 1.

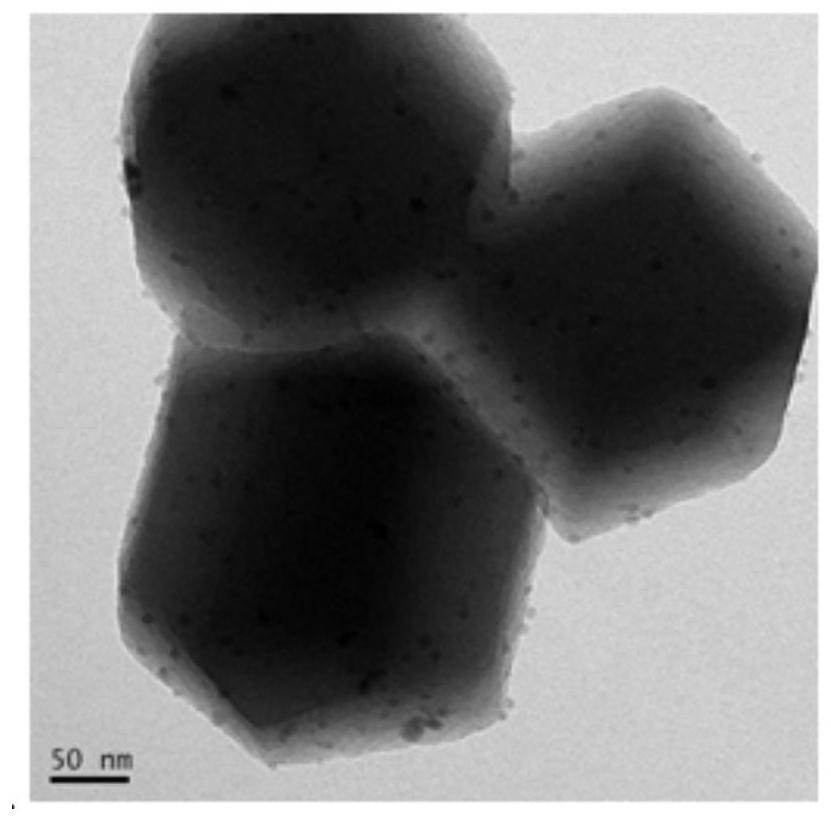

[0066] The lithiated separators obtained in Example 1 and Comparative Example 1 were tested by transmission electron microscopy, and the results were shown in image 3 and Figure 4 ; image 3 is the TEM image of the lithiated separator obtained in Example 1, Figure 4 TEM image of the lithiated separator obtained in Comparative Example 1.

[0067] Comparing the SEM image-TEM image of Example 1 with the SEM image-TEM image of Comparative Example 1, it can be seen that the lithiation in Example 1 is uniform, while in Comparative Example 1 there are still some active part...

Embodiment 3

[0070] S1. Take 3.0842g of biphenyl and put it into a wide-mouthed bottle, then put the wide-mouthed bottle into a vacuumed glove box for subsequent operations, take 40 mL of anhydrous tetrahydrofuran and pour it into the wide-mouthed bottle, and then add 0.3000g Lithium-magnesium alloy, stir until the alloy no longer dissolves, and then stand for 0.5h to obtain a dispersed lithiation solution.

[0071] S2, put the Zif-20 coating diaphragm (specification is the same as Example 1) into the lithiation solution and soak for 3h, take out, wash with tetrahydrofuran until the surface of the diaphragm is colorless, and air dry naturally to obtain the lithiated diaphragm. The preparation of the above-mentioned lithiation solution and the immersion of the separator were carried out at room temperature (21° C.).

[0072] Setting a control sample: follow the process of Example 3, except that the lithium-magnesium alloy is replaced with a lithium sheet, and the time for the separator to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com