Straw treatment method and straw feed obtained by method

A treatment method and straw technology, applied in the field of straw treatment, can solve the problems of high acid content, diarrhea, and poor palatability, and achieve the effects of high sugar retention rate, increased food intake, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

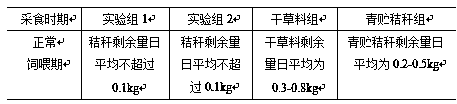

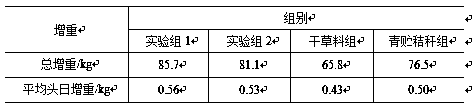

Embodiment 1

[0030] A method for processing stalks, comprising the following steps:

[0031] Step 1: Roll the harvested straw once to destroy the skin structure of the straw, and carry out the second rolling at an interval of 1-2 days. Each rolling should not make the sugar water flow out;

[0032] Step 2: drying the rolled straw to make the water content reach 14.0%.

[0033] In this embodiment, the moisture content of the harvested corn stalks is 67.3%.

Embodiment 2

[0035] A method for processing stalks, comprising the following steps:

[0036] Step 1: Cut the harvested straw into sections, and control the length of each section to 2-3 cm, and dry for 1-2 days;

[0037] Step 2: Roll the dried straw once to destroy the skin structure of the straw so as not to let the sugar water flow out;

[0038] Step 3: drying the rolled straw to make the water content reach 15.2%.

[0039] In this embodiment, the moisture content of the harvested straw is 50.6%.

Embodiment 3

[0041] A method for processing stalks, comprising the following steps:

[0042]Step 1: Roll the harvested straw three times to destroy the skin structure of the straw. The interval between each rolling is 1-2 days, and the sugar water should not flow out for each rolling;

[0043] Step 2: drying the rolled straw to make the water content reach 16.7%.

[0044] In this embodiment, the moisture content of the harvested straw is 56.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com