Preparation method of metal sulfide

A technology of metal sulfide and metal ions, applied in chemical instruments and methods, copper sulfide, zinc sulfide, etc., can solve the problems of environmental pollution, S2- entering the atmosphere or water, etc., and achieve large specific surface area, high yield, and structure Unit Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

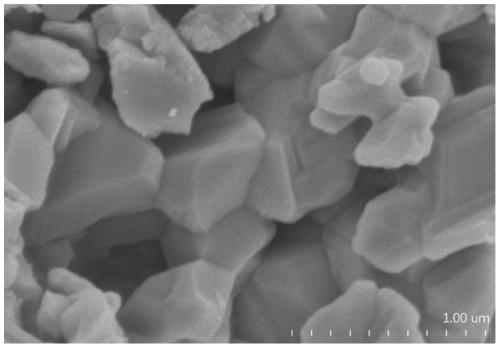

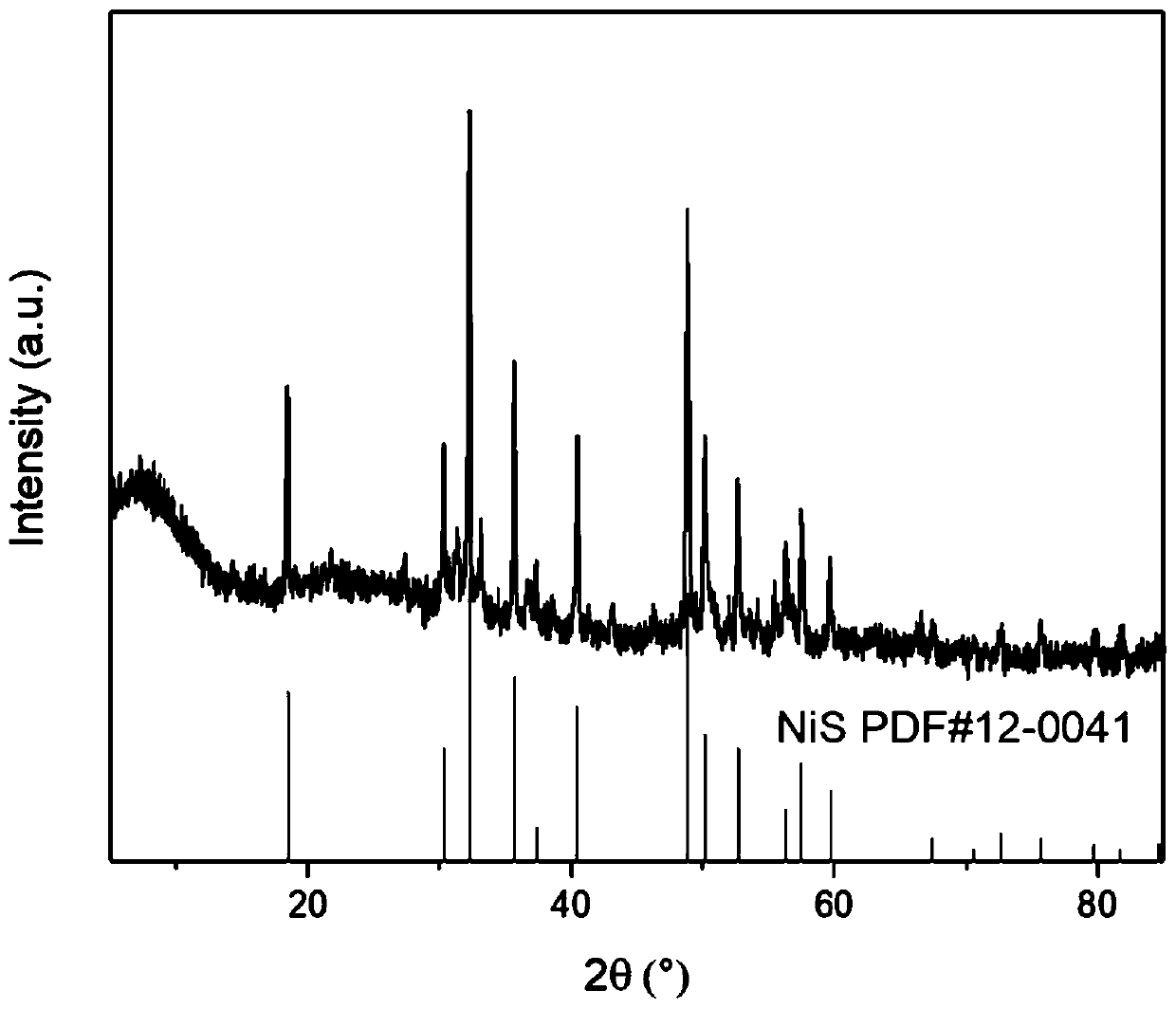

Embodiment 1

[0027] 1) Add 0.320g of thiocyanuric acid to 5ml of DMF, and stir at room temperature until a yellow clear and transparent solution is formed, which is designated as solution A;

[0028] 2) 0.450g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) added to 5ml of DMF, stirred at 50°C until a clear solution was formed, which was designated as solution B;

[0029] 3) With stirring at room temperature, add solution A dropwise to solution B, and the solution immediately becomes turbid, accompanied by continuous precipitation of brown precipitates;

[0030] 4) The above-mentioned brown precipitate was collected by vacuum filtration, washed three times with distilled water and ethanol, and then dried at a constant temperature of 60° C. under vacuum conditions for 12 hours;

[0031] 5) heat treatment is carried out to the precipitate after drying, and the heat treatment process is: in N 2 Heat up to 600°C at a rate of 5°C / min in the atmosphere, keep warm for 2 hours and then coo...

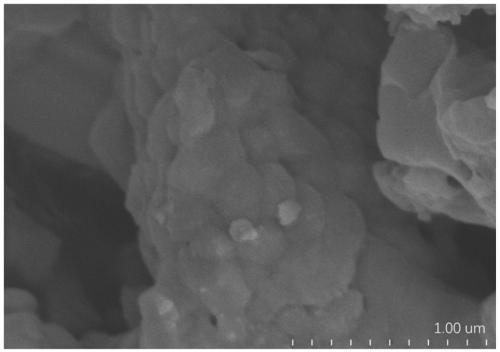

Embodiment 2

[0034] 1) Add 0.320g of thiocyanuric acid to 5ml of DMF, stir vigorously at 30°C until a yellow clear and transparent solution is formed, which is designated as solution A

[0035] 2) 0.450g cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) added to 5ml of DMF, stirred vigorously at 50°C until a clear solution was formed, which was designated as solution B;

[0036] 3) Stir at 30°C, add solution A dropwise to solution B, the solution immediately becomes turbid, accompanied by continuous precipitation of brown precipitates (the ratio of Co to S is 1:1);

[0037] 4) The above-mentioned brown precipitate was subjected to vacuum filtration, washed three times with distilled water and ethanol, and then dried at 60° C. under constant temperature and vacuum conditions for 12 hours;

[0038] 5) heat treatment is carried out to the precipitate after drying, and the heat treatment process is: in N 2 In the atmosphere, the temperature is raised to 500°C at a rate of 10°C / min, and a...

Embodiment 3

[0041] 1) Add 0.320g of thiocyanuric acid to 5ml of DMF, and stir vigorously at 40°C until a yellow clear and transparent solution is formed, which is designated as solution A

[0042] 2) 0.396g zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) add it to 5ml of DMF, and stir vigorously at 50°C until a clear solution is formed, which is referred to as solution B;

[0043] 3) Stir at 40°C, add solution A drop by drop to solution B, the solution immediately becomes turbid, accompanied by continuous precipitation of white precipitates (the ratio of the amount of Zn to S is 1:1);

[0044] 4) The above-mentioned white precipitate was subjected to vacuum filtration, washed three times with distilled water and ethanol, and then dried at a constant temperature of 60° C. under vacuum conditions for 12 hours;

[0045] 5) heat treatment is carried out to the precipitate after drying, and the heat treatment process is: in N 2 In the atmosphere, the temperature was raised to 400°C at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com