High-temperature-resistant ink composition, preparation method and application method

An ink composition and high temperature resistant ink technology are applied in the field of ink to achieve the effects of improving adhesion, good adhesion and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

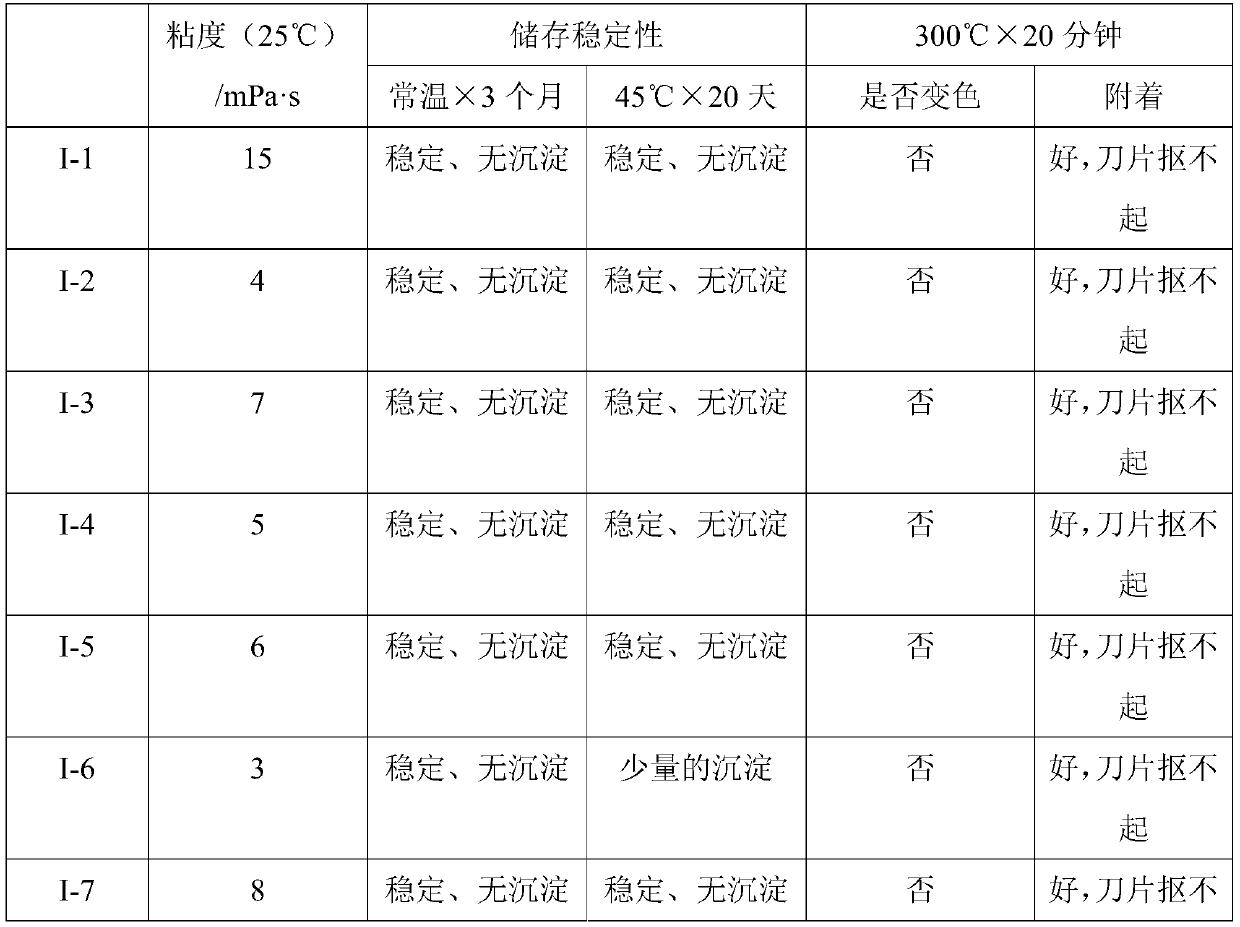

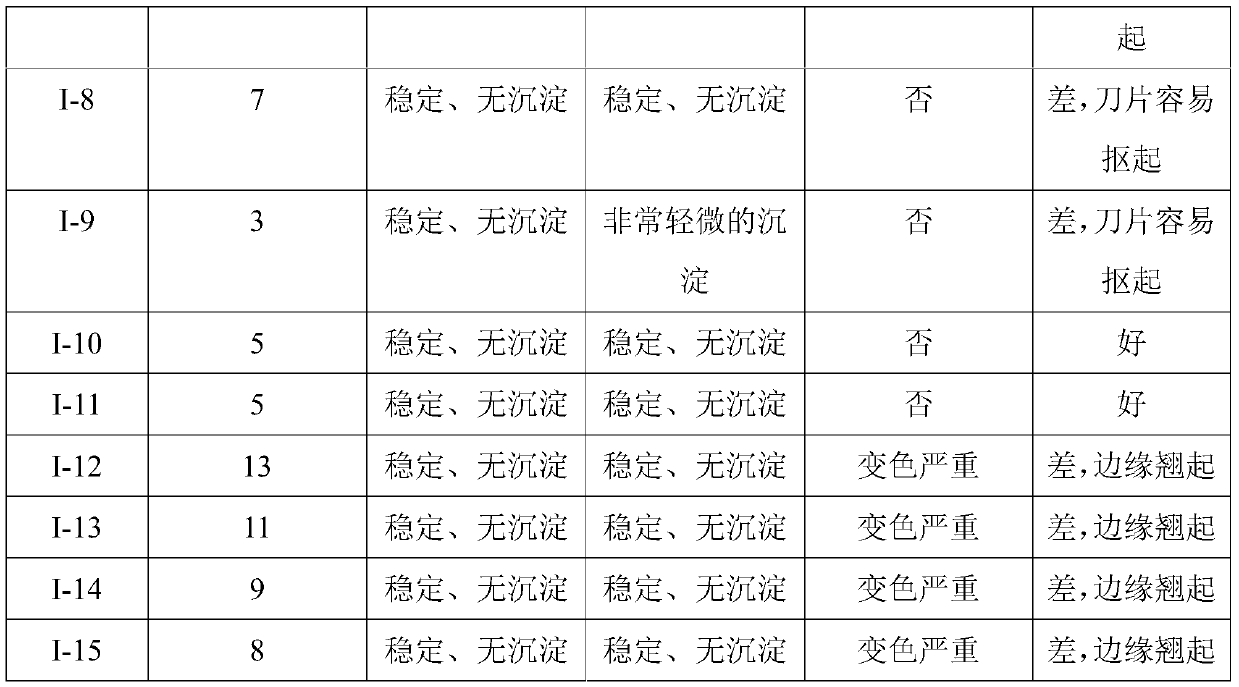

Examples

Embodiment 1

[0028] According to the formula: 20 parts of polyester modified methyl phenyl silicone resin, 0.5 parts of hydrogen heptaphenyl cage octapolysilsesquioxane, 15 parts of titanium dioxide, 0.5 parts of polymer dispersant, 0.5 parts of gas phase method Silicon dioxide, 0.4 parts of silicone defoamer, 1.5 parts of 3-glycidyloxypropyltrimethoxysilane, 10 parts of n-butanol and 25 parts of dipropylene glycol monomethyl ether, prepare raw materials.

[0029] Mix the titanium dioxide and the polyester-modified methylphenyl silicone resin evenly and grind them until the particle size does not exceed 1000nm to obtain a mixed material;

[0030] The above-mentioned mixed material, hydrogen-based heptaphenyl cage octapolysilsesquioxane, silicone defoamer, fumed silica, 3-glycidyl ether oxypropyltrimethoxysilane were dropped into n-butanol and In the organic solvent that dipropylene glycol monomethyl ether forms, stir to obtain ink slurry;

[0031] Send the above ink slurry into a high-she...

Embodiment 2

[0033] According to the formula: 50 parts of polyester modified methyl phenyl silicone resin, 1 part of octahydrocage octasilsesquioxane, 2 parts of hydrogen heptaphenyl cage octasilsesquioxane, 35 parts Titanium dioxide, 2 parts of polymeric dispersant, 1 part of organic bentonite, 0.8 parts of silicone defoamer, 5 parts of 3-aminopropyltrimethoxysilane, 35 parts of butyl acetate and 35 parts of propylene glycol monomethyl ether, prepared raw material.

[0034] Mix the titanium dioxide and the polyester-modified methylphenyl silicone resin evenly and grind them until the particle size does not exceed 1000nm to obtain a mixed material;

[0035] The above mixed material, octahydrocage octasilsesquioxane, hydrogen heptaphenyl cage octasilsesquioxane, silicone defoamer, organic bentonite, 3-aminopropyltrimethoxy The silane is sequentially dropped into an organic solvent composed of butyl acetate and propylene glycol monomethyl ether, and stirred evenly to obtain an ink slurry; ...

Embodiment 3

[0038] According to the formula: 30 parts of polyester modified methyl phenyl silicone resin, 0.3 parts of octahydrocage octasilsesquioxane, 1.2 parts of hydrogen heptamethyl cage octasilsesquioxane, 25 parts Titanium dioxide, 1 part of polymer dispersant, 0.8 part of polyamide wax, 0.5 part of silicone defoamer, 2 parts of 3-glycidyl etheroxypropyl trimethoxysilane and 50 parts of propylene glycol monomethyl ether, prepare raw materials.

[0039] Mix the titanium dioxide and the polyester-modified methylphenyl silicone resin evenly and grind them until the particle size does not exceed 1000nm to obtain a mixed material;

[0040] The above mixed material, octahydrocage octasilsesquioxane, hydrogen heptamethyl cage octasilsesquioxane, silicone defoamer, polyamide wax, 3-glycidyl ether oxypropylene Trimethoxysilane is dropped into propylene glycol monomethyl ether successively, and the ink slurry is obtained by stirring evenly;

[0041] The above-mentioned ink slurry was fed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com