System for coproduction of nitrogen-containing heterocyclic chemicals and nitrogen-doped carbon through nitrogen-rich catalytic pyrolysis

A technology for catalytic pyrolysis and nitrogen heterocycles, applied in chemical instruments and methods, inorganic chemistry, chemical/physical processes, etc., can solve the problem of low selectivity and yield of nitrogen-rich pyrolysis liquid products, nitrogen-doped carbon porosity and Nitrogen content is not high, to achieve the effect of high-value utilization, high-efficiency utilization, and full progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

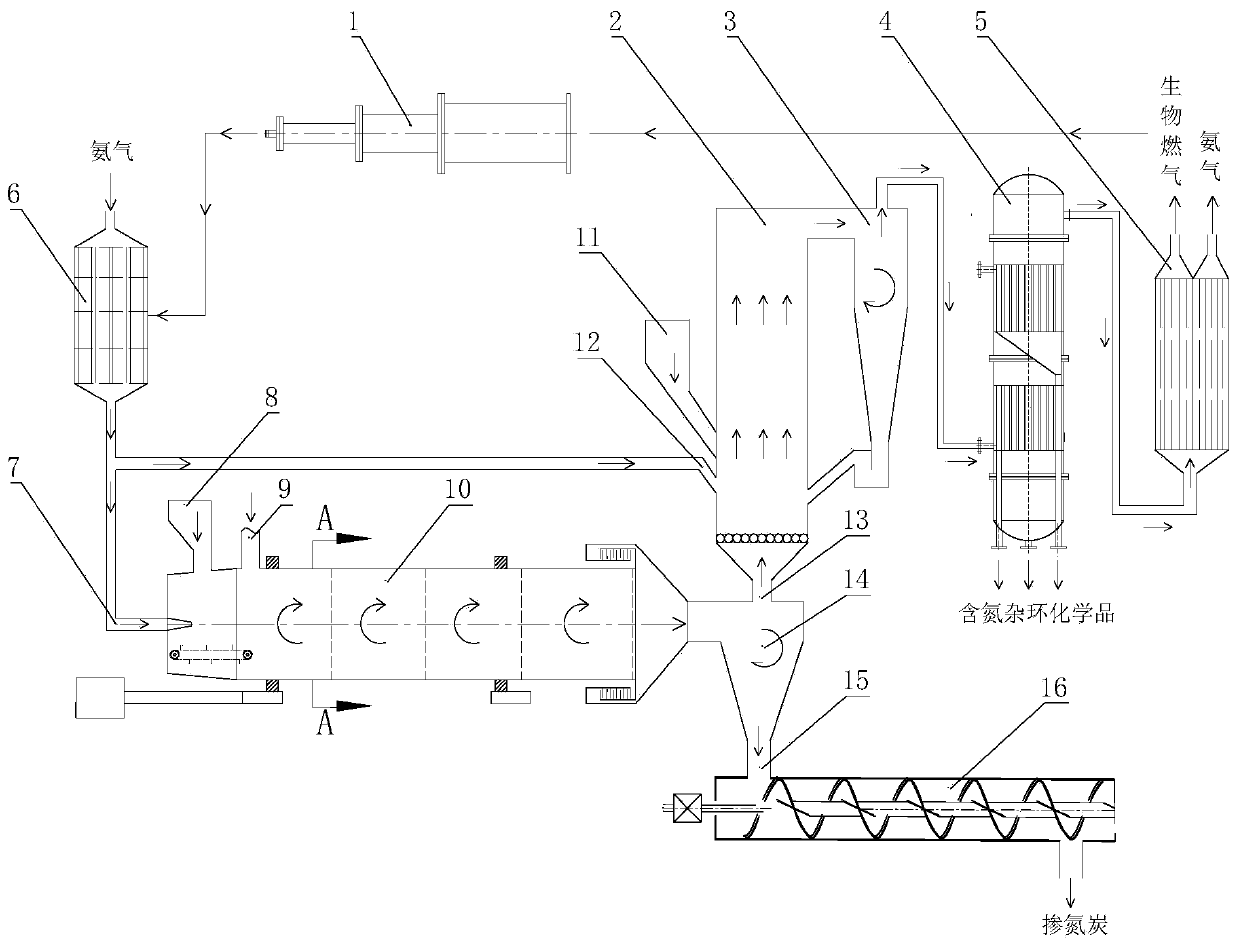

[0031] figure 1 Shown is a schematic structural diagram of the system for co-producing nitrogen-containing heterocyclic chemicals and nitrogen-doped carbon by nitrogen-enriched pyrolysis in this embodiment. The system includes interconnected organic solid waste nitrogen-rich pyrolysis activation subsystem, nitrogen-containing compound catalytic conversion subsystem, ammonia gas recycling and energy supply subsystem,

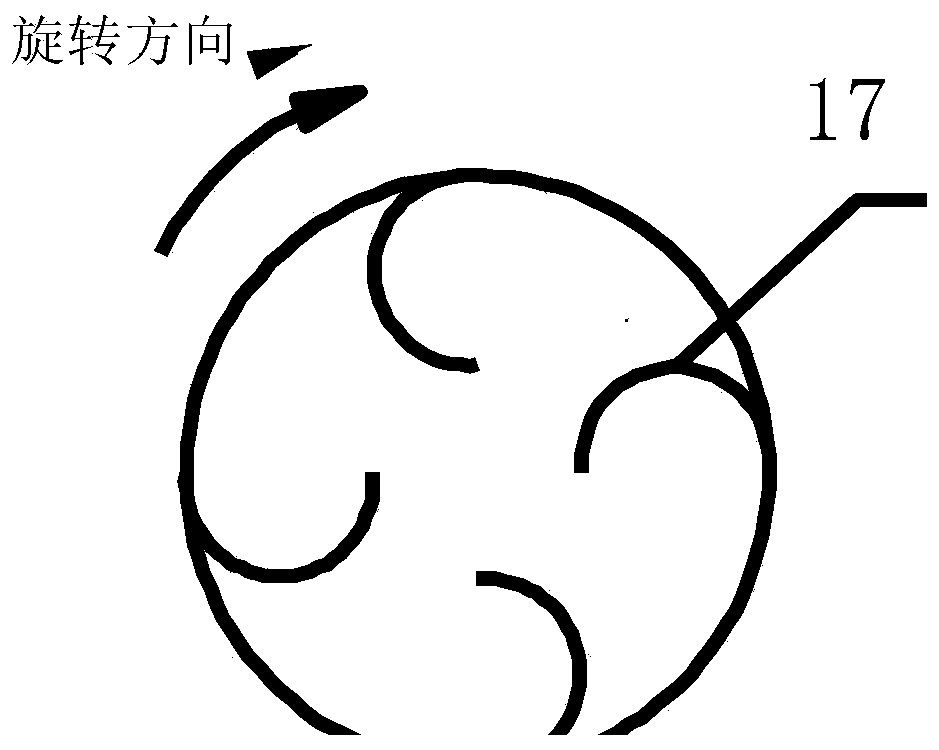

[0032] Among them, the organic solid waste nitrogen-rich pyrolysis activation subsystem includes an organic solid waste nitrogen-rich pyrolysis activation rotary furnace 10 (length is 3m, diameter is 0.8m), and is arranged at one end of the organic solid waste nitrogen-rich pyrolysis activation rotary furnace 10 The high temperature ammonia gas nozzle 7, the organic solid waste feed bin 8, the activator introduction pipe 9, and the rotating mixing plates 17 (such as figure 2 shown), the organic solid waste feeding bin 8 and the activator introduction pipe 9 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com