Preparation method of 3D reticular high-crystallinity walnut shell-based nanocellulose

A technology of nanocellulose and high crystallinity, which is applied in pulping of cellulose raw materials, post-treatment of cellulose pulp, post-treatment and modification of cellulose pulp, etc., can solve the problem of low utilization rate of walnut shells, low economic added value, Pollution of the environment and other problems, to achieve the effect of adding added value, superior performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Walnut shells are washed, dried, crushed, and passed through a 200-mesh sieve to obtain walnut shell powder.

[0030] 2. Take 5g of walnut shell powder and wrap it with filter paper, put it into 150mL of a mixture of toluene and absolute ethanol with a volume ratio of 2:1, extract at 145°C for 12 hours to remove pigments and lipids, and take out the wrapped walnut shell The filter paper bag of powder is dried at room temperature for 12 hours to obtain defatted walnut shell powder.

[0031] 3. Add 5g of defatted walnut shell powder to 200g of deionized water, add 2.8g of sodium chlorite and 2g of glacial acetic acid, heat and stir in a water bath at 75°C for 1 hour, then add 2.8g of sodium chlorite and 2g of ice Acetic acid, continue to react for 1 hour, repeat like this 5 times, and react for 6 hours in total. After the reaction is completed, filter and wash with deionized water to neutrality, and dry at 80°C to obtain hemcellulose.

[0032] 4. Mix 5 g of cellulose...

Embodiment 2

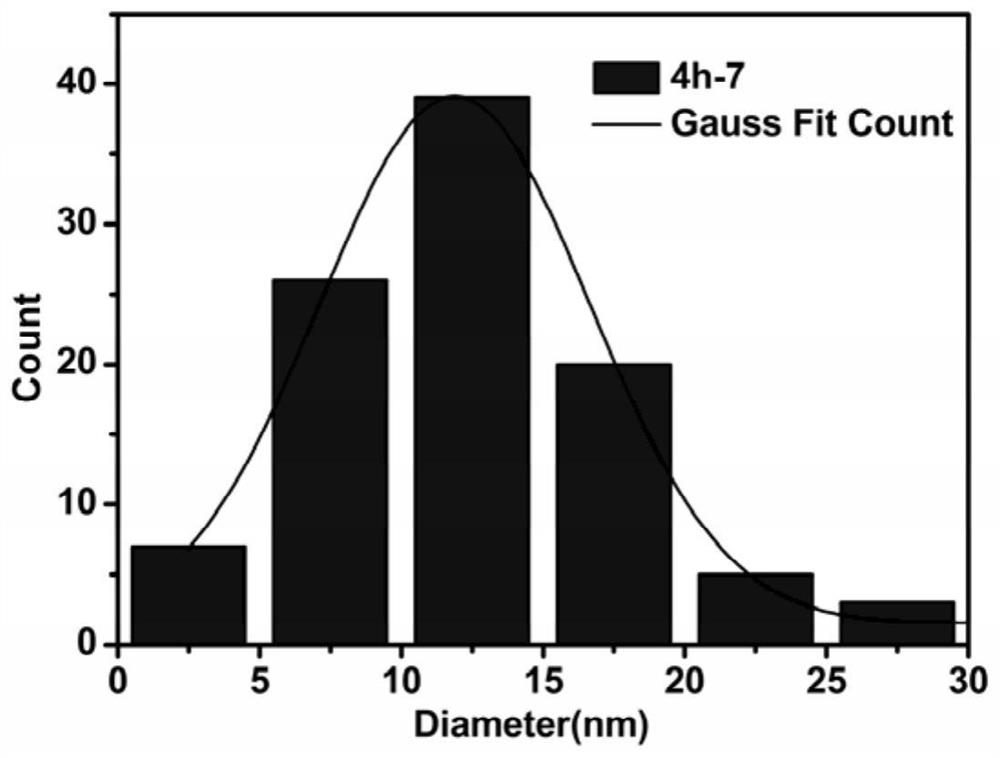

[0036] In step 5 of the present embodiment, 200 g of the diluent was taken, and 0.032 g of 2,2,6,6-tetramethylpiperidine oxide, 0.2 g of sodium bromide, and 3.56 g of sodium hypochlorite were added, and the other steps were the same as in Example 1. Three-dimensional network nanocellulose was obtained. Depend on Figure 4 It can be calculated that the crystallinity of the nanocellulose prepared in this example is 83.32%, which is higher than the crystallinity of commercial nanocellulose, and the Zeta potential of the nanocellulose dispersion is -48.00mV, indicating that the surface has a large amount of negative charges. The nanocellulose is relatively stable.

Embodiment 3

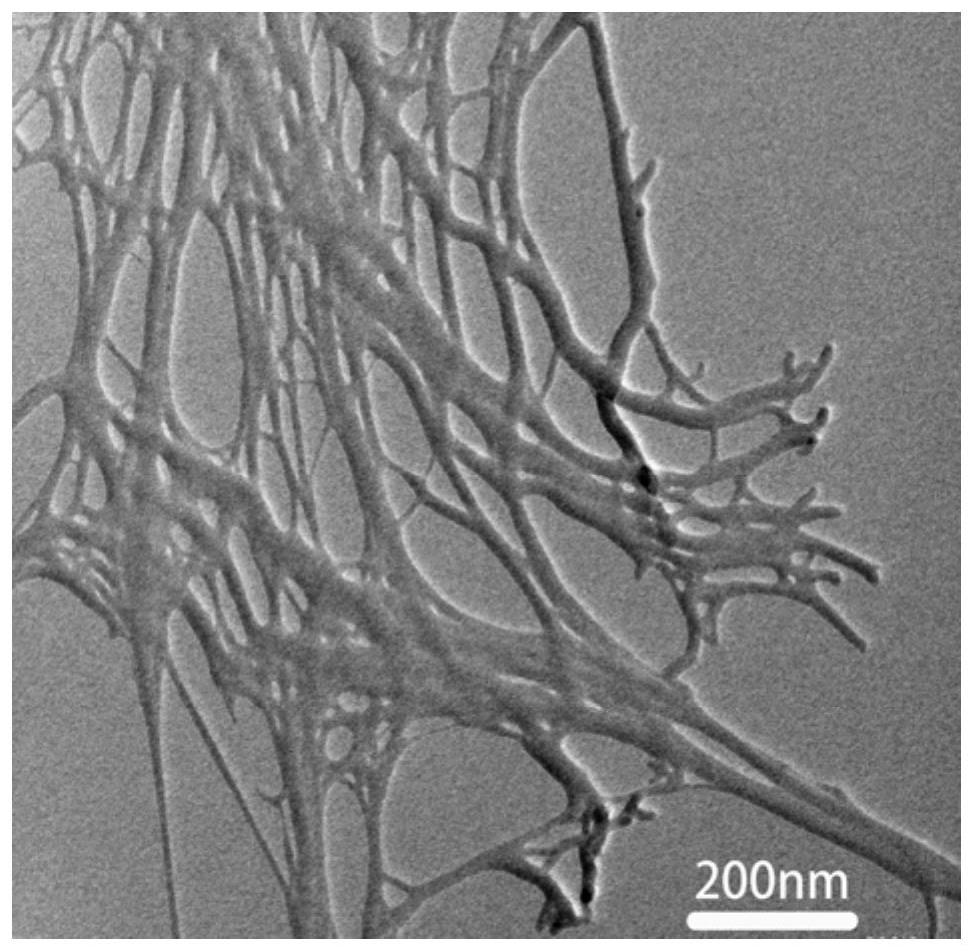

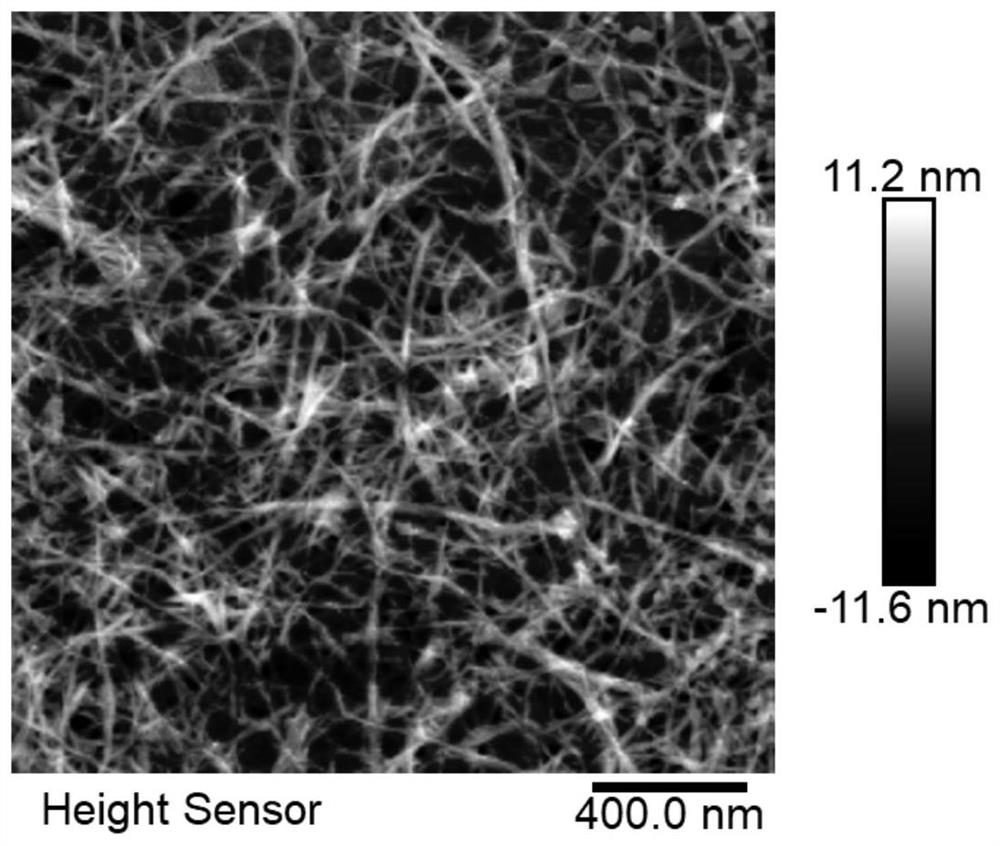

[0038] In the step 5 of this embodiment, get 200g diluent, add 0.032g 2,2,6,6-tetramethylpiperidine oxide, 0.2g sodium bromide, 10.65g sodium hypochlorite, other steps are the same as in Example 1, A three-dimensional network nanocellulose was obtained. Depend on Figure 5 It can be seen that the cellulose fibers are interconnected and interlaced, with a network structure, and the fiber diameter is below 50nm, reaching the nanometer level. Figure 4 It can be calculated that the crystallinity of the nanocellulose prepared in this example is 84.84%, which is higher than the crystallinity of commercial nanocellulose, and the Zeta potential of the nanocellulose dispersion is -30.47mV, indicating that the surface has a large amount of negative charges, and the prepared The nanocellulose is relatively stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com