Temperature switch system and application thereof to increment of yield of amino acids

A technology of temperature switch and threonine, applied in the fields of genetic engineering and microbial fermentation, can solve the problems of difficulty in accumulating oxaloacetic acid and low conversion rate of oxaloacetic acid derivatives, and achieve high-efficiency fermentation production, rapid biomass accumulation, The effect of shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

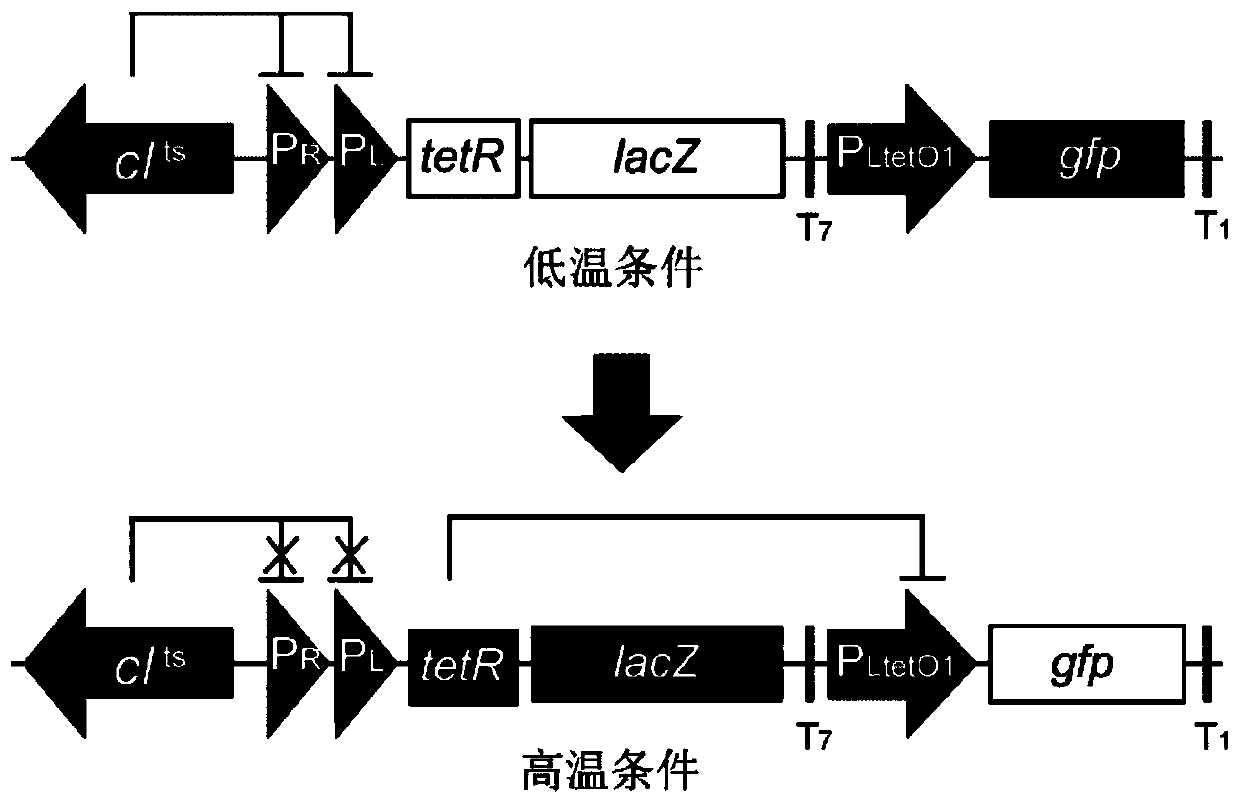

[0073] Embodiment 1 temperature switch carrier construction and characterization

[0074] (1) Construction of temperature switch carrier

[0075] Based on the plasmid pFW001 (containing triclosan resistance and high copy number pMB1 replicon), the medium copy number replicon p15A was used to replace pMB1, and the temperature switch loop was used to replace the PJ23101 promoter to obtain a temperature switch vector. The plasmid pFW001 is derived from a paper published in 2018: Zhao, H., Fang, Y., Wang, X., Zhao, L., Wang, J., Li, Y., 2018.Increasing L-threonine production in Escherichia coli by engineering the glyoxylate shunt and the L-threonine biosynthesis pathway.

[0076] The temperature switch circuit includes the temperature sensitive circuit cI ts -p R -p L , the TetR repressor gene tetR and the tightly regulated promoter P LtetO-1 . These genes were obtained by chemical synthesis. In order to obtain independent genetic regulation, dual multiple cloning sites (MC...

Embodiment 2

[0087] Embodiment 2 Application of temperature switch system to improve the production capacity of threonine strains

[0088] (1) Optimization and transformation of threonine production strains:

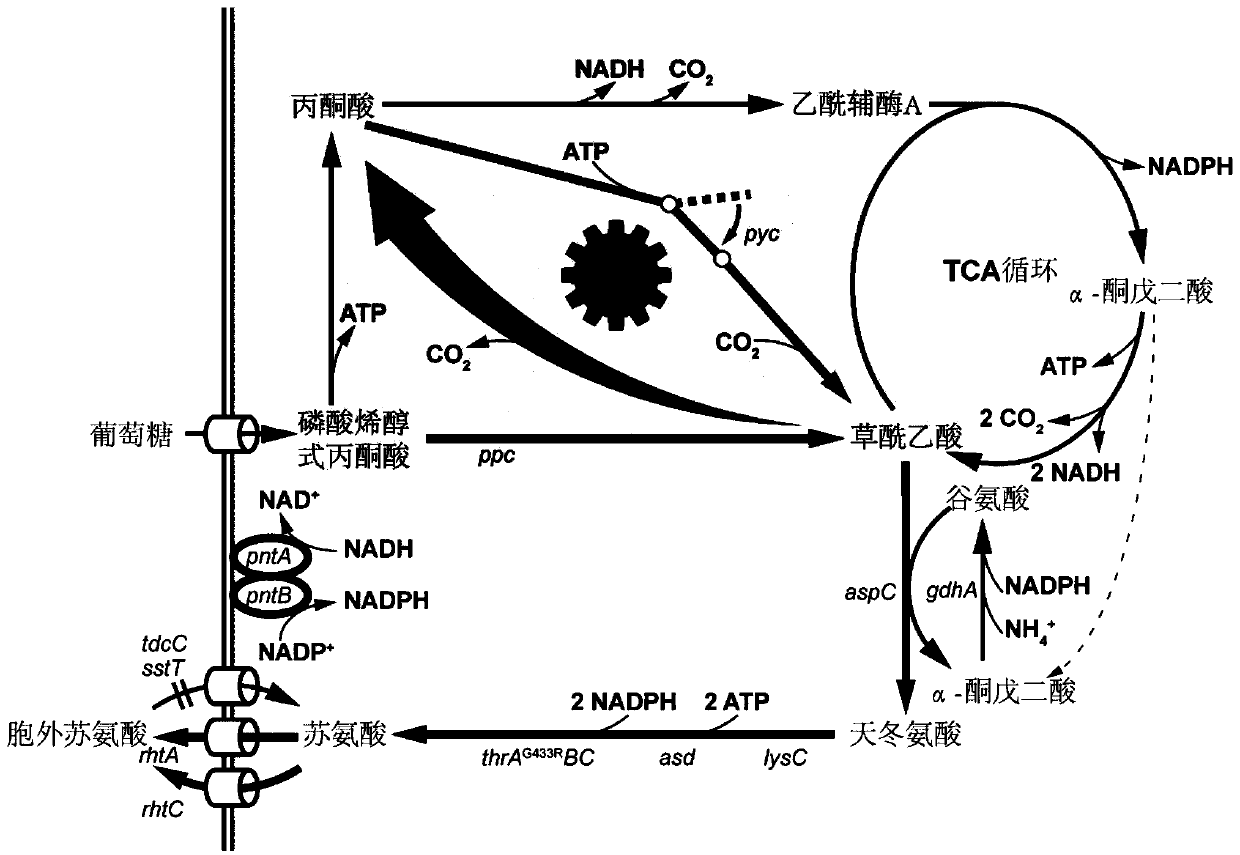

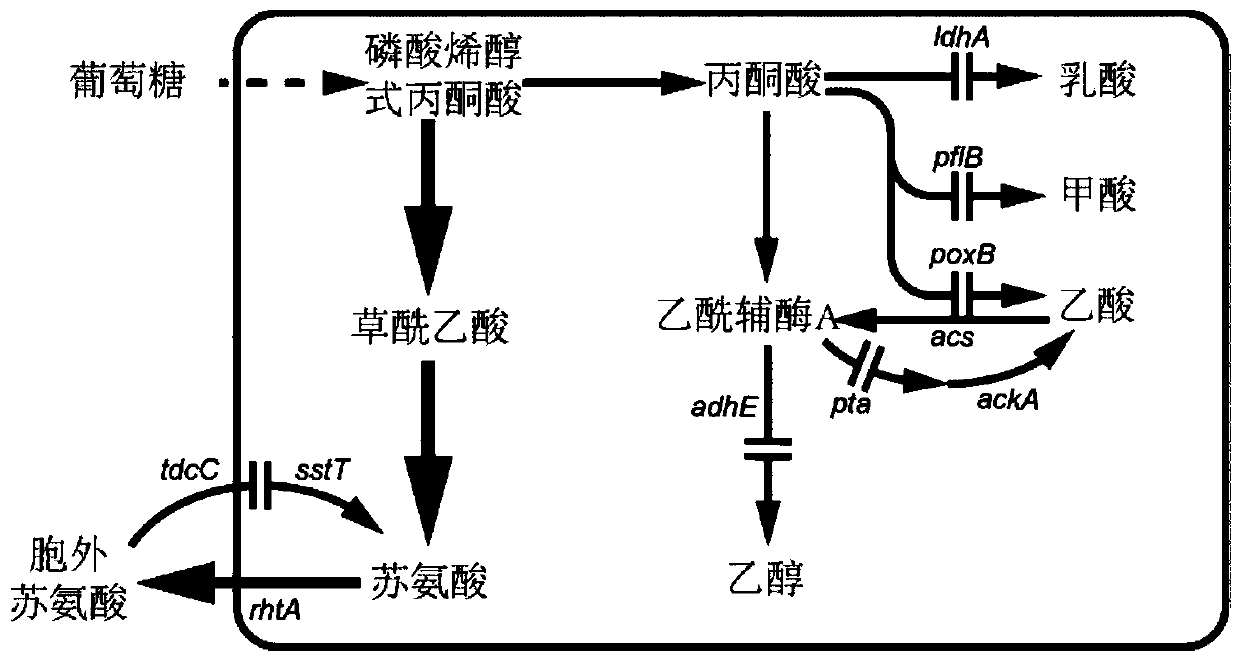

[0089] Taking TWF001 as the starting strain, the genome of this strain has overexpressed pyridine nucleotide transhydrogenase (pntAB) and related genes involved in threonine production (ppc, aspC, lysC, asd, thrA G433R BC and rhtA) (see figure 1 ). To improve the threonine production performance of the strain and reduce waste of carbon sources, some unimportant genes related to organic acid synthesis (poxB, pflB, ldhA, adhE, and pta) and a gene encoding a threonine transporter (tdcC) were knocked out, respectively. except (see figure 2 ), thereby producing platform strains TWF102, TWF103, TWF104, TWF105, TWF106, TWF107, TWF108, as shown in Table 1. These platform strains were subjected to shake-flask fermentation to produce threonine at 37°C constant temperature and variable te...

Embodiment 3

[0097] Embodiment 3 fermentation produces threonine

[0098] STF seed medium is based on LB medium and obtained after optimization and improvement. After adjusting the content of sucrose and peptone in the LB medium, it was used to cultivate the TWF001 strain, and the growth status and threonine production of the strain in the seed medium with different components were detected (such as Figure 8 shown). The results showed that the threonine yield of TWF001 was 15.37g / L, which was 50.54% higher than that of LB as the seed medium, when STF seed medium was used as the seed medium and fermented in a constant temperature shake flask at 37°C for 18 hours.

[0099] Recombinant strains TWF106 / pFT24r, TWF106 / pFT24p, TWF106 / pFT24pm and TWF106 / pFT24rp were fermented in variable temperature shake flasks (such as Figure 10 shown), its threonine yields are 17.24g / L, 20.15g / L, 20.60g / L and 23.29g / L respectively, and the corresponding molar sugar-acid conversion rates are 72.44%, 81.50%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com