Silicon-carbon composite material, preparation method and application thereof

A silicon-carbon composite material and carbon nanomaterial technology, which is applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of silicon-carbon structure hindering electron/lithium ion transport performance, etc., and achieve excellent structure/interface stability. , the effect of alleviating volume expansion, improving structure and interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

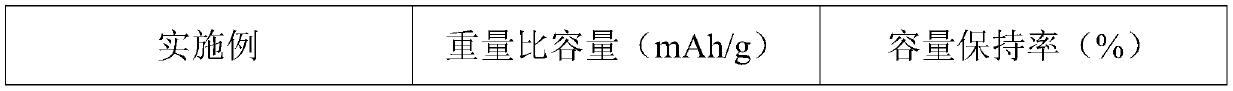

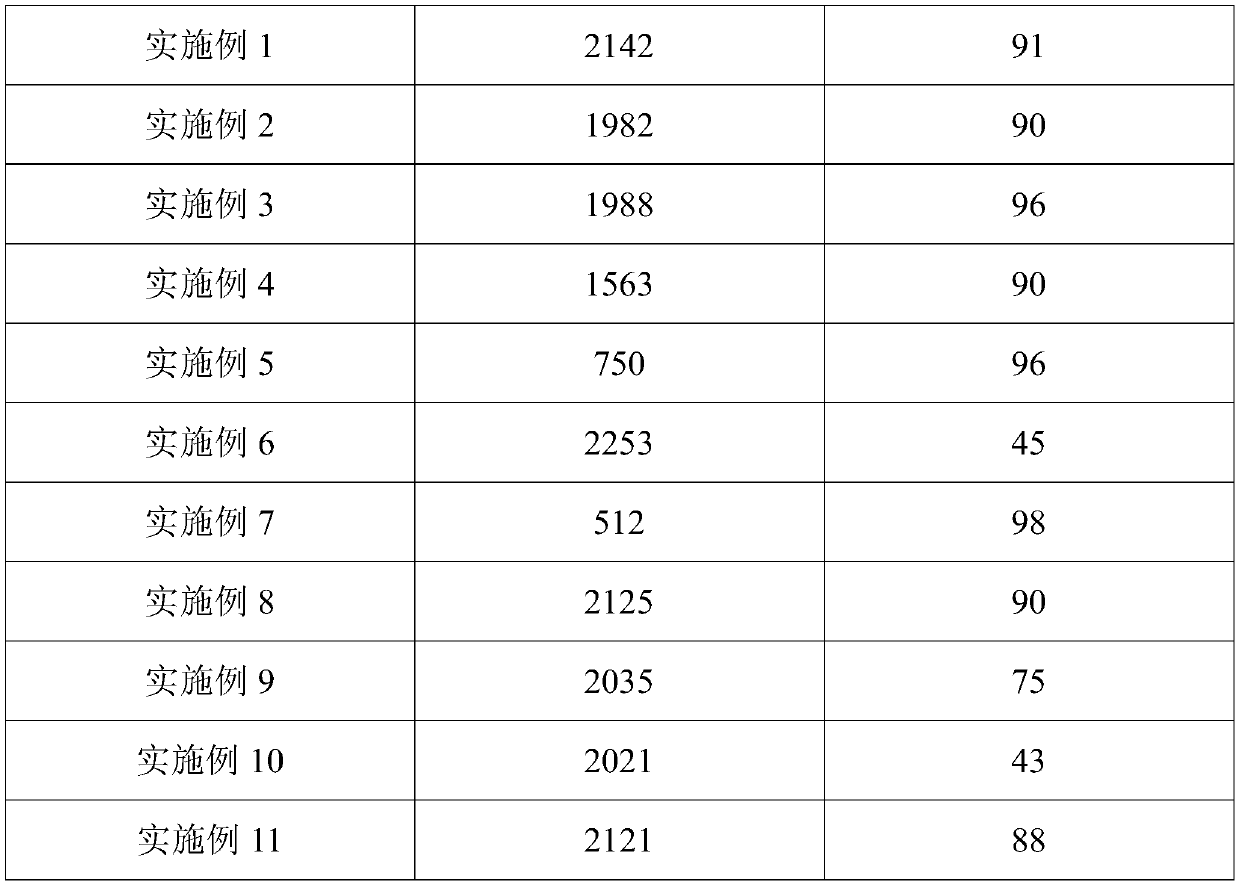

Examples

Embodiment 1

[0056] This embodiment provides a silicon-carbon composite material, including two-dimensional carbon nanomaterials, two-dimensional silicon nanomaterials, and two-dimensional carbon nanomaterials that are composited face-to-face from top to bottom, and the mass percentage of silicon in the silicon-carbon composite material is The thickness of the two-dimensional silicon nanomaterial is 6nm, and the ratio of the length of the short side to the thickness is 15. The preparation method is as follows: put the two-dimensional silicon nanomaterial prepared by the magnesia thermal reduction method into a high-temperature tube furnace, evacuate through a vacuum device, replace argon, and repeat 3 times to ensure an oxygen-free environment; operate the equipment at 100 sccm h 2 / Ar mixed gas (H 2 The volume fraction is 5%), the temperature is raised to 1100°C at a speed of 5°C / min, and CH is introduced at a speed of 50sccm 4 , keep warm for 20min, and deposit graphene on the two-dime...

Embodiment 2

[0060] This embodiment provides a silicon-carbon composite material, including two-dimensional carbon nanomaterials, two-dimensional silicon nanomaterials, and two-dimensional carbon nanomaterials that are composited face-to-face from top to bottom, and the mass percentage of silicon in the silicon-carbon composite material is The thickness of the two-dimensional silicon nanomaterial is 5.4nm, and the ratio of the length of the short side to the thickness is 20. The preparation method is as follows: disperse the two-dimensional silicon nanomaterial prepared by the chemical oxidation exfoliation method in 1% glucose aqueous solution, add graphene oxide, sonicate for 1 hour, filter, put the filtered material into a high-temperature tube furnace, and pass through a vacuum Vacuumize the device, replace argon, repeat 3 times to ensure an oxygen-free environment; run the equipment at 100 sccm of H 2 / Ar mixed gas (H 2 The volume fraction is 5%), the temperature was raised to 900° C...

Embodiment 3

[0064] This embodiment provides a silicon-carbon composite material, including two-dimensional carbon nanomaterials, two-dimensional silicon nanomaterials, and two-dimensional carbon nanomaterials that are composited face-to-face from top to bottom, and the mass percentage of silicon in the silicon-carbon composite material is is 90%, the thickness of the two-dimensional silicon nanomaterial is 5.4nm, and the aspect ratio is 20. The preparation method is as follows: put the two-dimensional silicon nanomaterials prepared by the chemical oxidation stripping method into a high-temperature tube furnace, evacuate through a vacuum device, replace argon, and repeat 3 times to ensure an oxygen-free environment; h 2 / Ar mixed gas (H 2 The volume fraction is 5%), the temperature is raised to 1100°C at a speed of 5°C / min, and CH is introduced at a speed of 50sccm 4 , keep warm for 10 minutes, and deposit graphene on the two-dimensional silicon nanomaterial to obtain the silicon-carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com