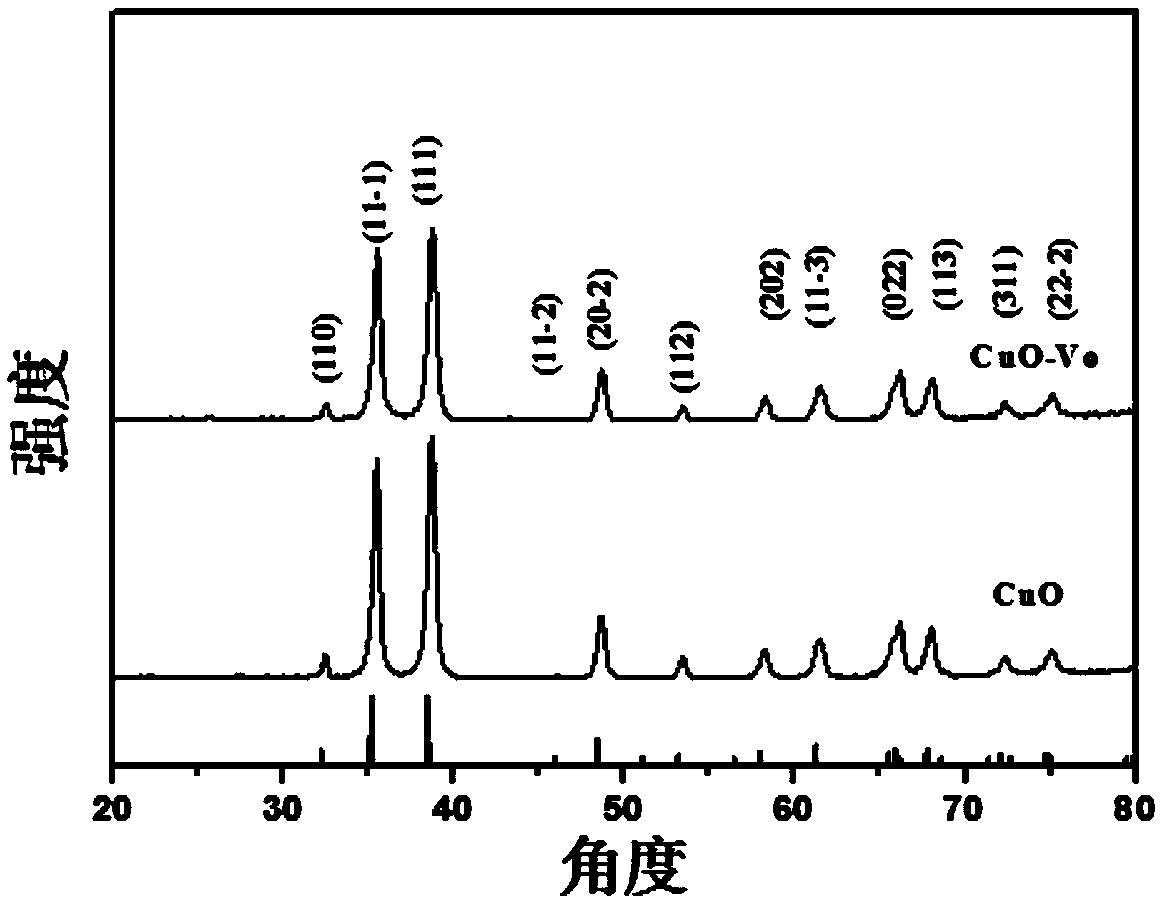

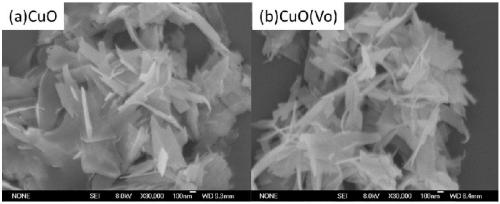

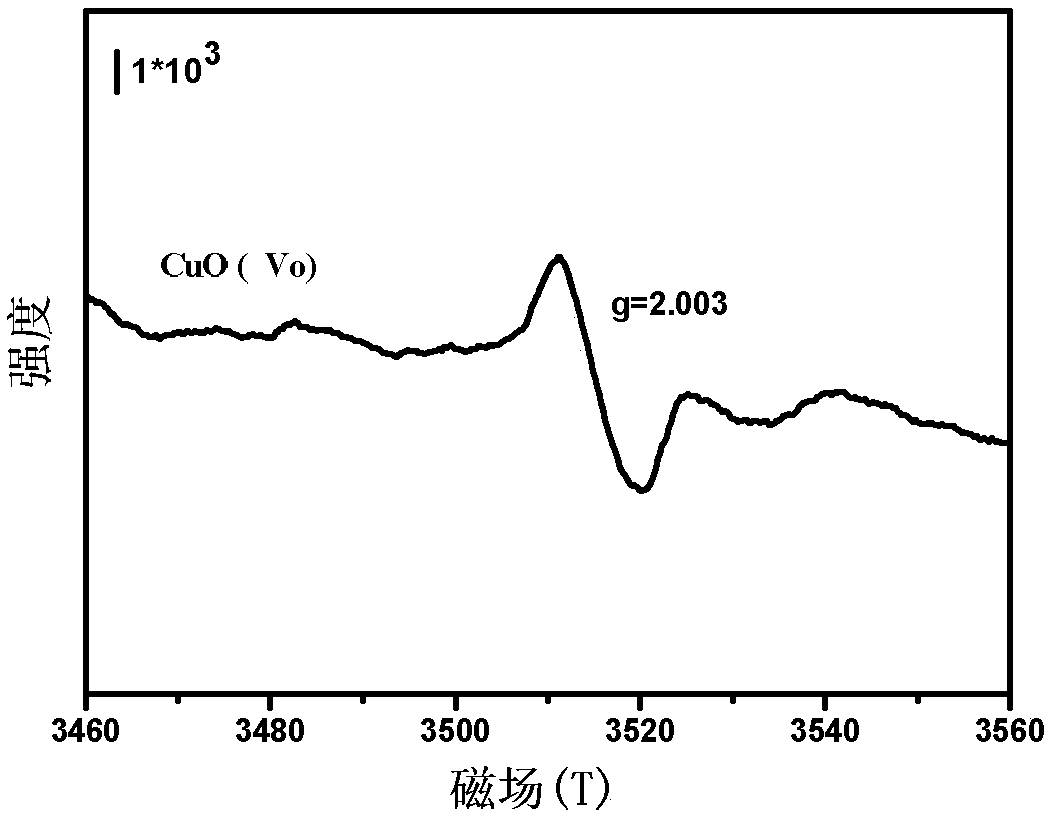

Method for producing oxygen vacancy-containing CuO nanosheets

A manufacturing method and technology of nanosheets, applied in chemical instruments and methods, copper oxide/copper hydroxide, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high reaction temperature, composition and morphology Control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for manufacturing a CuO catalyst containing oxygen vacancies, which mainly includes the following steps:

[0034] (1) Preparation of CuO nanosheets

[0035] Step 1: Dissolve 60g of sodium hydroxide (NaOH) and 11g of cetyltrimethylammonium bromide (CTAB) in 450ml of distilled water, pour the mixed solution into a 1000ml round bottom flask, and heat up to 60 °C, recorded as solution A.

[0036] Step 2: take by weighing 1.7g copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) Dissolve in 50ml distilled water, record as solution B.

[0037] Step 3: Slowly add solution B to solution A, and keep stirring during the addition process to obtain a blue solid-liquid mixture.

[0038] Step 4: After reacting for 60 minutes, a solid-liquid mixture is obtained. After standing still for a period of time, the supernatant is filtered off, and the precipitate is washed by suction filtration with water and ethanol. A black powder was obtained.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com