Application of iron (II) doped molybdenum sulfide material in self-energized piezoelectric enhanced hydrogen production

A molybdenum sulfide piezoelectric and molybdenum sulfide technology, applied in the production of molybdenum sulfide and hydrogen, catalyst activation/preparation, etc., can solve the problems of high cost, low abundance and limited application of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

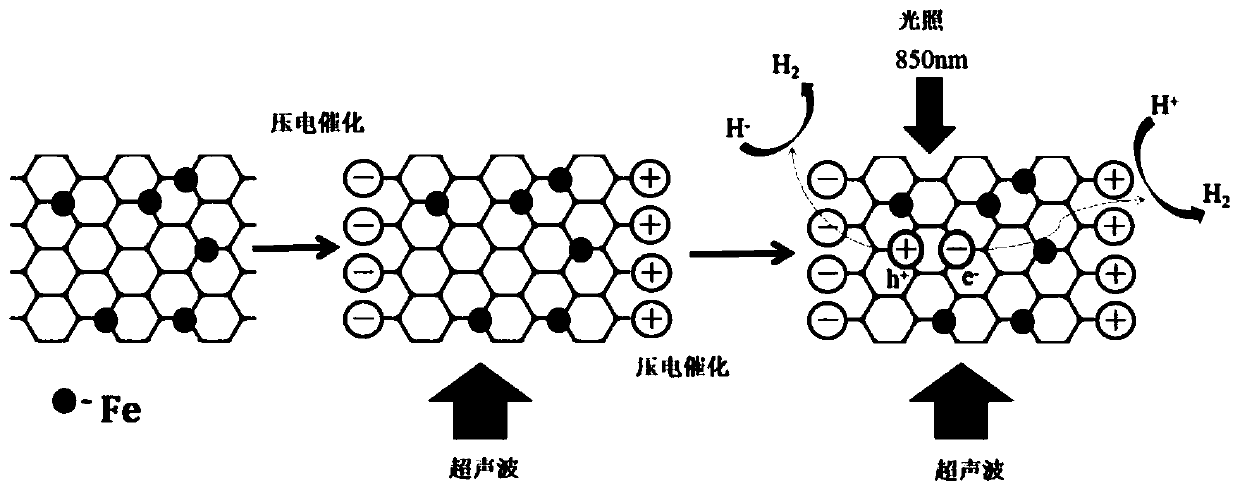

[0043] Further, the iron (II) doped molybdenum sulfide material is prepared by a hydrothermal method, and the preparation method includes the following steps:

[0044] (1) Sodium molybdate was dissolved in deionized water, and ultrasonically treated for 30-60mins to mix uniformly to obtain solution A;

[0045] (2) Dissolve thiourea in deionized water, and sonicate for 30-60mins until mixed uniformly to prepare solution B;

[0046] (3) dissolving ferrous chloride tetrahydrate in deionized water, and ultrasonic treatment for 30-60mins to mix uniformly to prepare solution C;

[0047] (4) Add solution B and solution C dropwise to solution A, and ultrasonically treat for 30-60mins until mixed uniformly to obtain mixed solution D;

[0048] (5) Transfer the mixed solution D to a high-pressure reactor, and react at a temperature of 150-300° C. for 20-30 hours to prepare an iron (II)-doped molybdenum sulfide material.

[0049] Further, the concentration of the solution A is 0.1mol / L~...

Embodiment 1

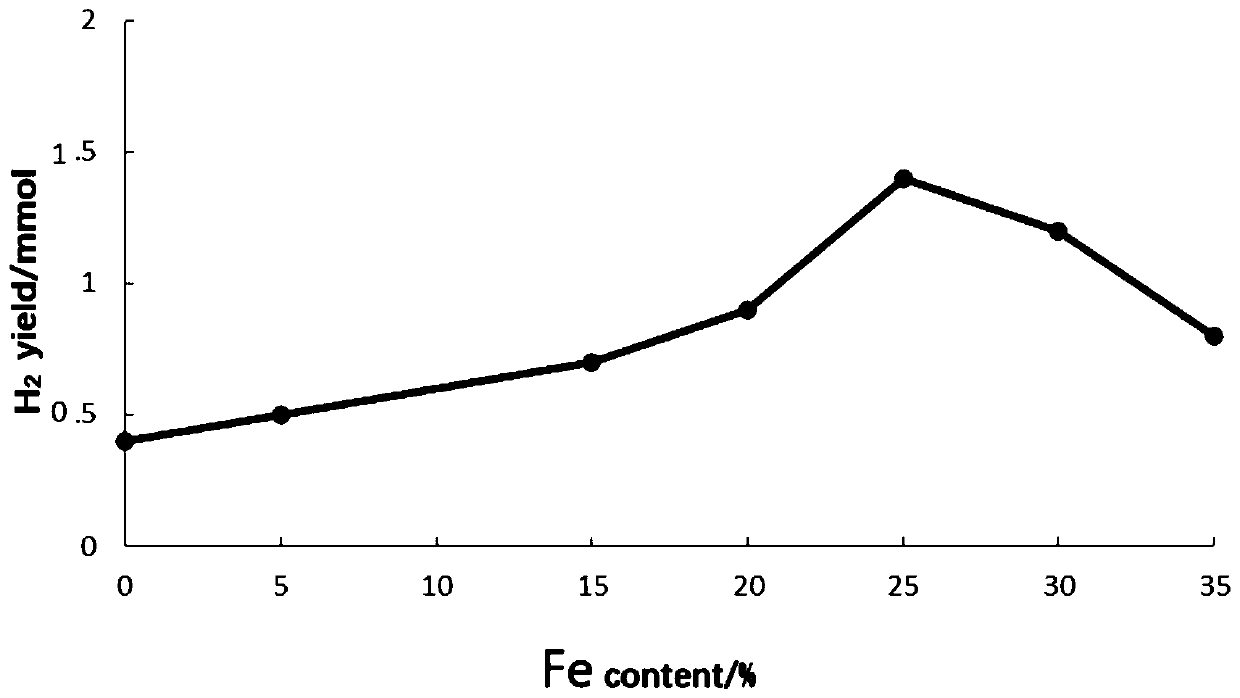

[0063] Iron(II) Doped Molybdenum Sulfide Material Fe-MoS as Piezoelectric Enhancement Material 2 Preparation of semiconductor materials in which the mass of Fe is MoS 2 10% of the mass.

[0064] (1) 2.42g (0.01mol) sodium molybdate (NaMoO 4 2H 2 O) be dissolved in deionized water, and ultrasonic treatment 30mins to mix homogeneously to prepare solution A;

[0065] (2) 3.05g (0.04mol) thiourea [(NH 2 ) 2 CS] was dissolved in deionized water, and ultrasonically treated for 30mins until uniformly mixed to obtain solution B;

[0066] (3) 0.190g (0.0015mol) of ferrous chloride tetrahydrate was dissolved in deionized water, and ultrasonically treated for 60mins until mixed uniformly to obtain solution C;

[0067] (4) Add solution B and solution C dropwise to solution A, and ultrasonically treat for 60mins until mixed uniformly to obtain mixed solution D;

[0068] (5) Set the volume of the mixed liquid D to 100mL and transfer it to a high-pressure reactor. The temperature is c...

Embodiment 2

[0074] Iron(II) Doped Molybdenum Sulfide Material Fe-MoS as Piezoelectric Enhancement Material 2 Preparation of semiconductor materials in which the mass of Fe is MoS 2 15% of the mass.

[0075] (1) 2.42g (0.01mol) sodium molybdate (NaMoO 4 .2H 2 O) be dissolved in deionized water, and ultrasonic treatment 30mins to mix homogeneously and make mixed solution A;

[0076] (2) 3.05g (0.04mol) thiourea [(NH 2 ) 2 CS] was dissolved in deionized water, and ultrasonically treated for 30mins until mixed uniformly to obtain mixed solution B;

[0077] (3) 0.285g (0.00224mol) ferrous chloride tetrahydrate was dissolved in deionized water, and ultrasonically treated for 60mins until mixed uniformly to obtain mixed solution C;

[0078] (4) Add mixed solution B and mixed solution C dropwise to mixed solution A, and ultrasonically treat for 60mins until mixed evenly to prepare mixed solution D;

[0079] (5) Set the volume of the mixed liquid D to 100mL and transfer it to a high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com