Basalt ferromagnetic glass fiber as well as preparation method and application thereof

A glass fiber and ferromagnetic technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high cost, complicated preparation method of glass batch materials, low output of magnetic glass fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of basalt ferromagnetic glass fiber, in order to prepare 500kg batch material, used raw material according to following mass ratio:

[0050]

[0051]

[0052] The preparation steps are as follows:

[0053] The above raw materials are mixed evenly by QH750 type mixer to obtain uniformly mixed batch materials, which are added to the glass furnace, melted, clarified and homogenized at 1500°C according to conventional melting conditions, and passed through the feeding channel The molten glass is transported to the discharge port and cooled to 1300°C. The molten glass flows down from the discharge port onto the fast-rotating spinner wheel, and the basalt ferromagnetic glass fiber is prepared by the spinning method.

[0054] The chemical composition of the basalt ferromagnetic glass fiber that the present embodiment makes is as follows, all are mass percentages:

[0055] SiO 2 : 34.45%, Al 2 o 3 : 11.54%, Fe 2 o 3 +FeO: 36.24%, B 2 o 3 : 3.43%, CaO: 7.39%...

Embodiment 2

[0061] A kind of basalt ferromagnetic glass fiber, in order to prepare 500kg batch material, used raw material according to following mass ratio:

[0062]

[0063] The preparation method is the same as in Example 1.

[0064] The chemical composition of the basalt ferromagnetic glass fiber that the present embodiment makes is as follows, all are mass percentages:

[0065] SiO 2 : 38.13%, Al 2 o 3 : 11.72%, Fe 2 o 3 +FeO: 31.69%, B 2 o 3 : 3.65%, CaO: 9.57%, MgO: 3.62%, Na 2 O: 1.62.

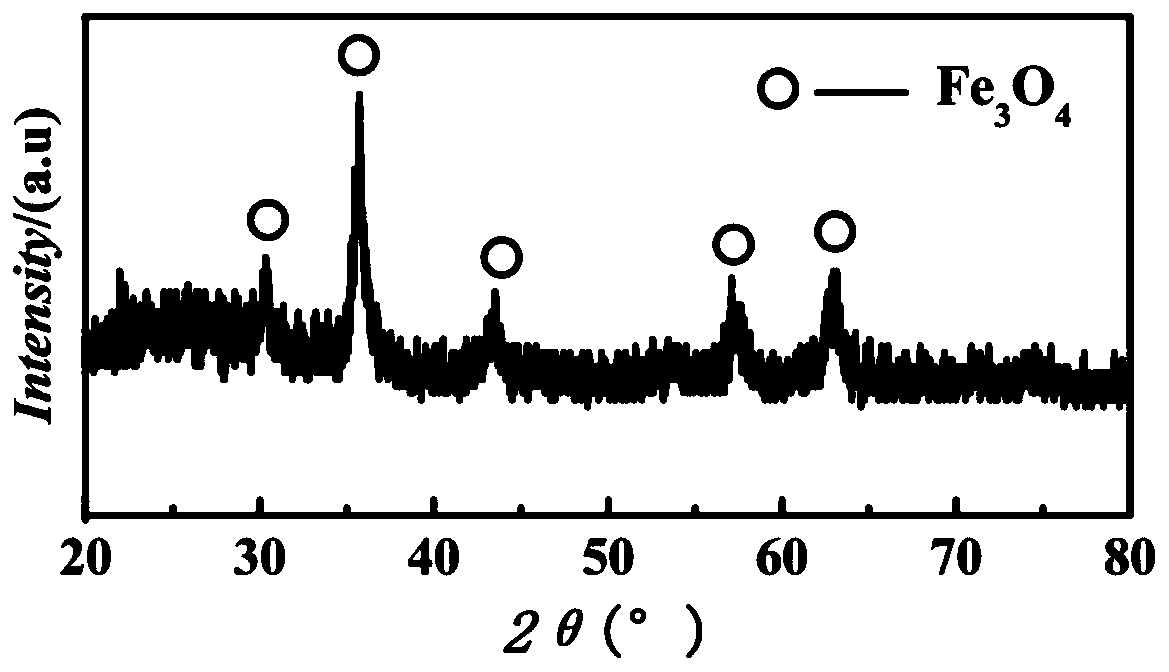

[0066] The XRD figure of the basalt ferromagnetic glass fiber that the present embodiment makes Figure 5 shown by Figure 5 It can be seen that the crystalline phase of the ferromagnetic glass fiber prepared in this example is Fe 3 o 4 .

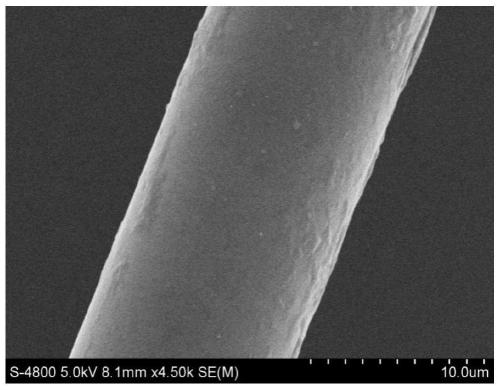

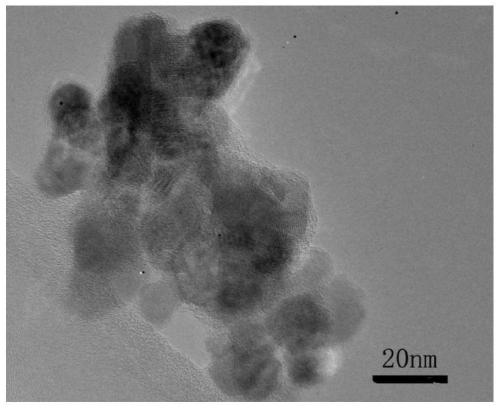

[0067] The scanning electron microscope picture of the basalt ferromagnetic glass fiber that the present embodiment makes is as Image 6 shown by Image 6 It can be seen that the diameter of the ferromagnetic glass fiber prepared in this examp...

Embodiment 3-6

[0071] The raw material ratio of embodiment 3-6 is as shown in table 1.

[0072] Table 1 Example 3-6 500kg batch required raw material ratio

[0073] Raw material\Example Example 3 Example 4 Example 5 Example 6 Basalt (kg) 237.44 323.28 346.68 266.05 Alumina powder (kg) 16.63 2.45 0.00 11.75 Iron oxide powder (kg) 150.39 118.8 95.34 136.94 Boric acid (kg) 48.92 24.98 48.71 48.37 Calcium carbonate (kg) 36.74 28.89 9.27 32.97 Magnesium oxide (kg) 9.88 1.60 0.00 3.92 total 500.00 500.00 500.00 500.00

[0074] The preparation steps are the same as in Example 1.

[0075] The chemical composition of the basalt ferromagnetic glass fiber that embodiment 3-6 makes is as shown in table 2, is mass percent:

[0076] Table 2 The chemical composition of the basalt ferromagnetic glass fibers prepared in Examples 3-6

[0077]

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com