3-methyl-3-butene-1-ol dehydration method and device

A technology of alcohol dehydration and butene, applied in chemical instruments and methods, preparation of hydroxy compounds, separation/purification of hydroxy compounds, etc., can solve problems such as inability to efficiently utilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

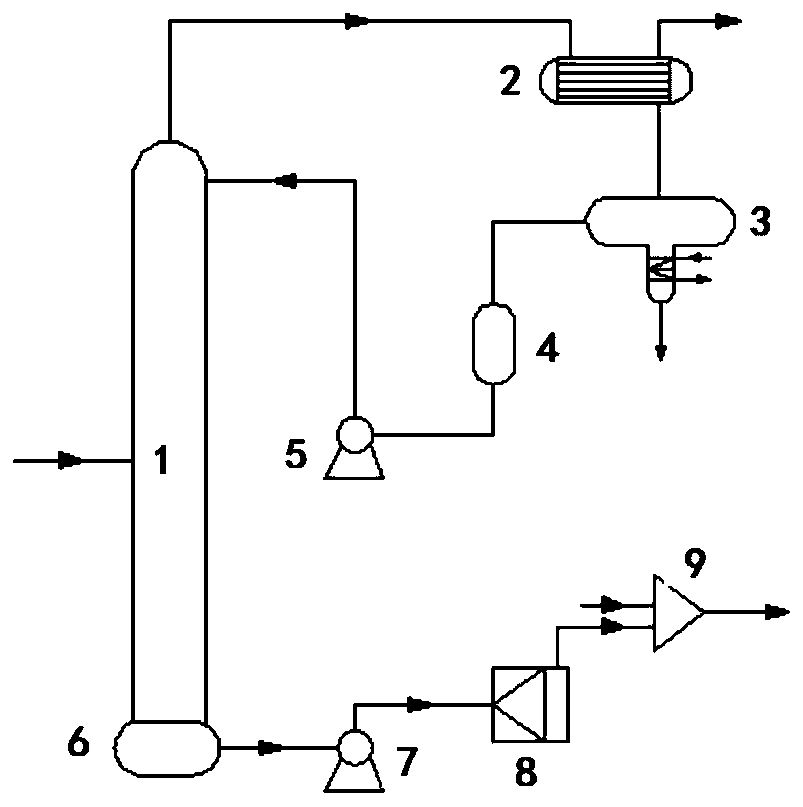

[0034] use figure 1The shown reaction device carries out the following operation process. In the rectification tower 1, feed the material at a rate of 200kg / h with a mass flow rate, open the steam inlet and outlet valves of the reboiler 6, control the temperature of the reboiler 6 at the bottom of the tower to be 95°C, and the vacuum pressure at the bottom of the tower to be -0.085MPa, open The chilled water inlet and outlet valves of the tower top condenser 2 are used to control the tower top temperature to 55°C and the tower top pressure to -0.088MPa. Open the ethylene glycol solution inlet and outlet valves of the freezing pipe at the bottom of the buffer tank 3 to control the temperature of the freezing pipe to 5°C. Keep the total reflux for 0.6h, open the drainage pipe of the freezing pipe, the drainage rate is 18kg / h, wait for the sample analysis of the top reflux pipe, when the water content is less than 1000ppm, stabilize for 10min, open the discharge pump of the recti...

Embodiment 2

[0036] use figure 1 The shown reaction device carries out the following operation process. In the rectification tower 1, feed the material at a rate of 201kg / h with a mass flow rate, open the steam inlet and outlet valve of the reboiler 6, control the temperature of the reboiler 6 at the bottom of the tower to be 98°C, and the vacuum pressure at the bottom of the tower to be -0.088MPa, open The chilled water inlet and outlet valves of the tower top condenser 2 control the tower top temperature to 58°C and the tower top pressure to -0.090MPa, open the ethylene glycol solution inlet and outlet valves of the freezing pipe at the bottom of the buffer tank 3, and control the freezing pipe temperature to 7°C. Keep the total reflux for 0.8h, open the drainage pipe of the freezing pipe, the drainage rate is 16kg / h, wait for the sample analysis of the top reflux pipe, when the water content is less than 1000ppm, stabilize for 10min, open the discharge pump of the rectification tower 1 ...

Embodiment 3

[0038] use figure 1 The shown reaction device carries out the following operation process. In the rectification tower 1, feed the material at a rate of 198kg / h with a mass flow rate, open the steam inlet and outlet valves of the reboiler 6, control the temperature of the reboiler 6 at the bottom of the tower to be 94°C, and the vacuum pressure at the bottom of the tower to be -0.082MPa, open The chilled water inlet and outlet valves of the tower top condenser 2 control the temperature of the tower top to 53°C and the pressure of the tower top to -0.085MPa, open the inlet and outlet valves of the ethylene glycol solution of the freezing pipe at the bottom of the buffer tank 3, and control the temperature of the freezing pipe to 8°C. Keep the total reflux for 0.5h, open the drainage pipe of the freezing pipe, the drainage rate is 15kg / h, wait for the sample analysis of the reflux pipe at the top of the tower, when the water content is less than 1000ppm, stabilize for 10min, open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com