Etchant composition for simultaneous etching of multilayer film having zinc oxide and silver

A zinc oxide and oxide technology, applied in the direction of surface etching composition, chemical instruments and methods, electrical components, etc., can solve the problems of large etching difference and low chemical resistance of zinc oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

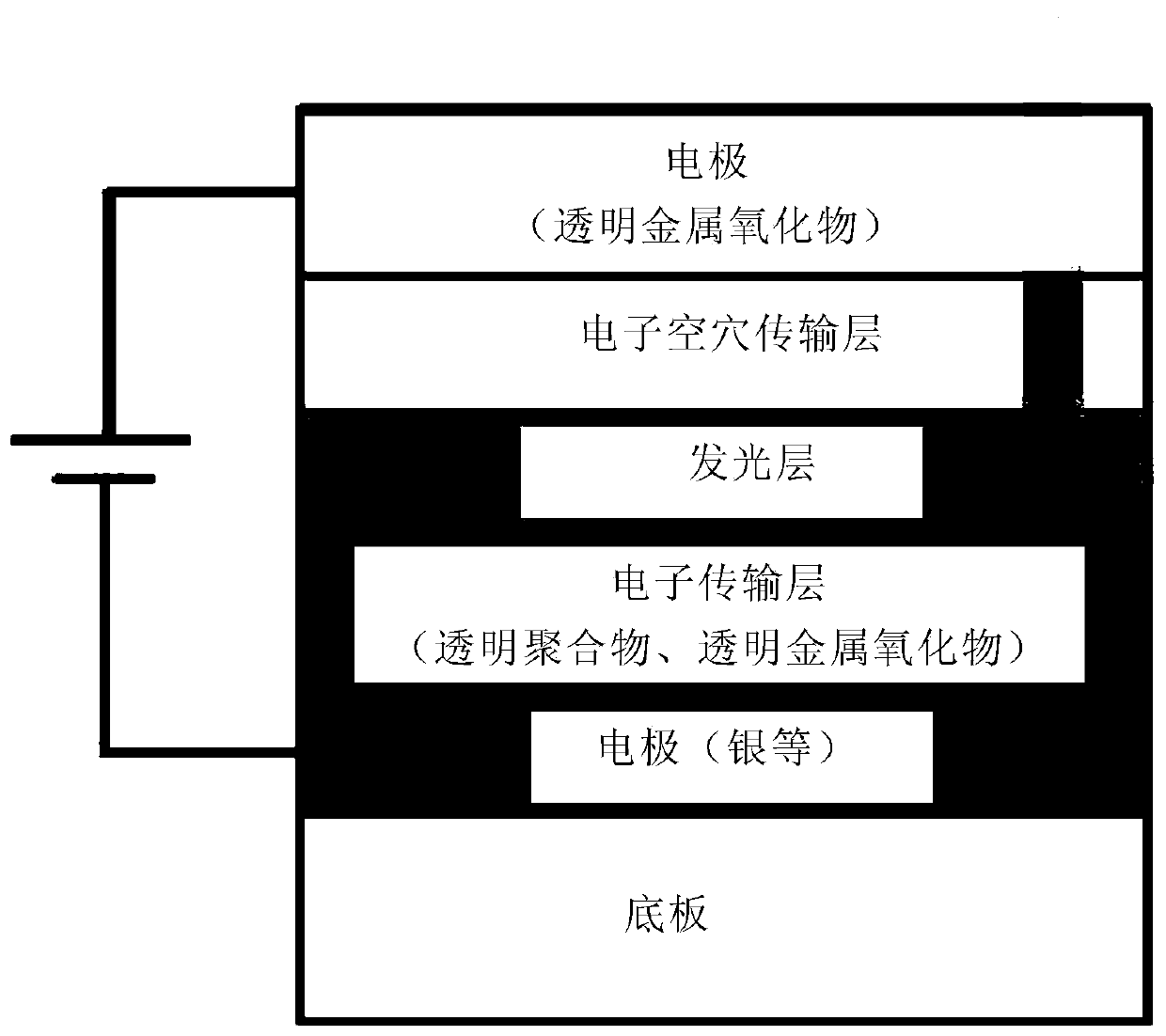

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

[0085] (Evaluation method of Example 14)

preparation Embodiment 9

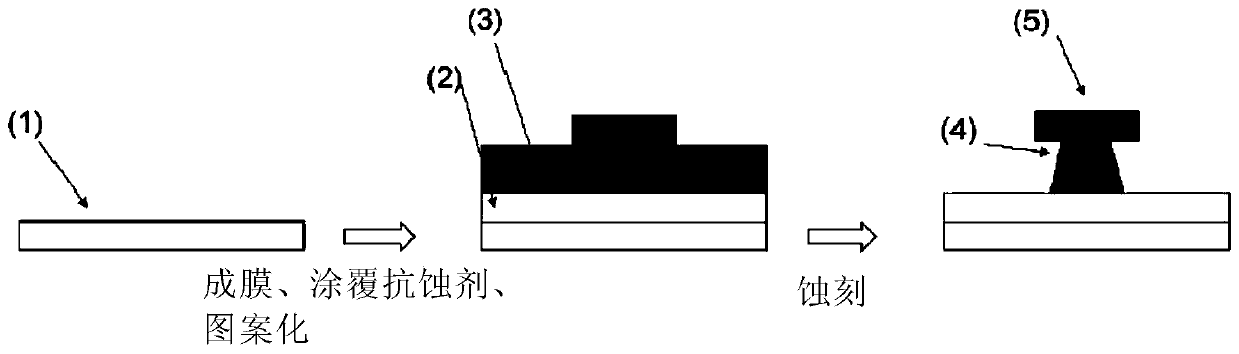

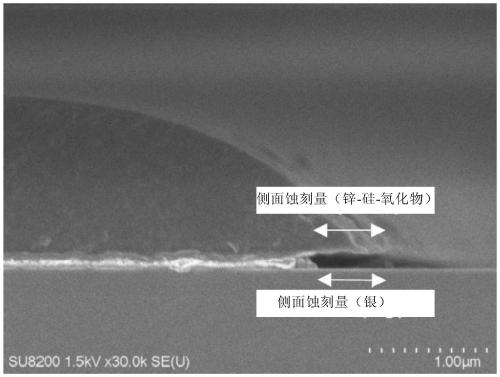

[0086] Such as figure 2 As shown, films of silicon nitride (200nm) (2), silver (100nm) (3), zinc-silicon-oxide (50nm) (4) were sequentially formed on a glass substrate (1), and a resist (5 ) patterned on it, and cut the bottom plate into a size of 15mm×15mm. After preparing the etching solution composition described in Example 9, the above etching solution composition was incubated at 30° C. for 20 minutes. The bottom plate was immersed in 40 mL of etching solution, stirred and etched at 30 °C. The etch time alone was 45 seconds. After immersion in the etching solution for 68 seconds, the bottom plate was washed with ultrapure water for 10 seconds, and dried under nitrogen flow. After cutting the bottom plate, the cross section was observed using FE-SEM (manufactured by Hitachi High-Tech Co., Ltd., model: SU8220). The cross-sectional shape observed by FE-SEM is as follows image 3 shown. The amount of side etching (S.E.) of zinc-silicon-oxide was 0.62 μm, and that of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com