Single-sided super-hydrophobic polymer fiber membrane and preparation method and application thereof

A hydrophobic polymer and polymer technology, which is applied in the field of membrane flue gas desulfurization, can solve the problems that the membrane contactor cannot operate stably for a long time, affects the membrane absorption flux, membrane wetting of the membrane contactor, etc., and achieves simple and reliable preparation steps. control, excellent desulfurization performance, and the effect of avoiding membrane wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a single-sided superhydrophobic polymer fiber membrane, comprising the following steps:

[0029] mixing the hydrophobic polymer, the hydrophobic nanoparticles, the first solvent and the second solvent to obtain a spinning solution;

[0030] Electrospinning the spinning solution on one side of the polymer base film to form a superhydrophobic fiber layer on one side of the polymer base film to obtain a single-side superhydrophobic polymer fiber film;

[0031] The boiling point difference between the first solvent and the second solvent is greater than or equal to 50° C., and the boiling point of the first solvent is lower than that of the second solvent.

[0032] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0033] In the invention, the hydrophobic polymer, the hydrophobic nano particles, the first solvent ...

Embodiment 1

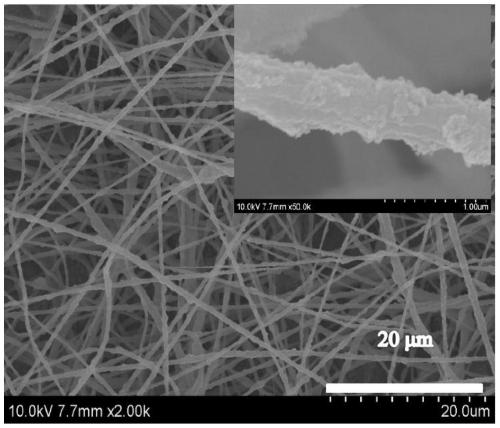

[0048] The superhydrophobic fiber layer of the single-sided superhydrophobic polyvinylidene fluoride fiber membrane is formed by electrostatic spinning of hydrophobic nano silicon dioxide (with a particle diameter of 20-40nm) and polyvinylidene fluoride.

[0049] The preparation method is as follows:

[0050] (1) Soak a commercially available polyvinylidene fluoride film in absolute ethanol solution at 25°C for 2 hours, take it out and dry it naturally, and dry it under vacuum for 24 hours to obtain a polyvinylidene fluoride-based film;

[0051] (2) Preparation of hydrophobic nano-silica-polyvinylidene fluoride spinning solution, the composition of the spinning solution is: polyvinylidene fluoride (1.6g), N,N-dimethylformamide (5.04g, boiling point 152 ℃), N-methylpyrrolidone (3.36g, boiling point 205 ℃), hydrophobic nano-silica accounts for 10% of the mass of polyvinylidene fluoride;

[0052] The preparation method of the spinning solution: Add 0.16g of hydrophobic nano-sili...

Embodiment 2

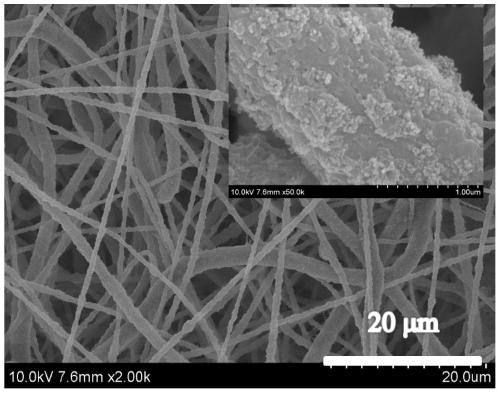

[0062] The difference from Example 1 is that the hydrophobic nano silicon dioxide accounts for 20% of the mass of polyvinylidene fluoride.

[0063] Performance Testing

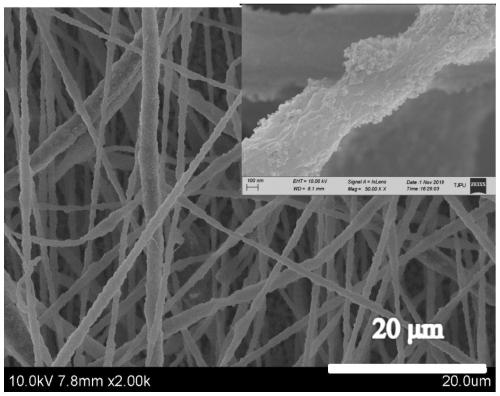

[0064] 1) Observe the obtained single-sided superhydrophobic polyvinylidene fluoride fiber membrane using a scanning electron microscope, the obtained results are as follows figure 2 As shown, the upper right corner of the figure is a detailed picture. According to the SEM image, it can be seen that strip-like protrusions appear on the surface of the film, and higher point-like protrusions appear on the surface of the strip-like protrusions, and the surface of the fiber is exposed to SiO 2 content increased.

[0065] 2) Test the water contact angle of the single-sided superhydrophobic polyvinylidene fluoride film obtained, wherein the side with the fiber layer is called the hydrophobic modified side, and the other side is called the unmodified side, and the results are shown in Table 2;

[0066] 3) Accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com