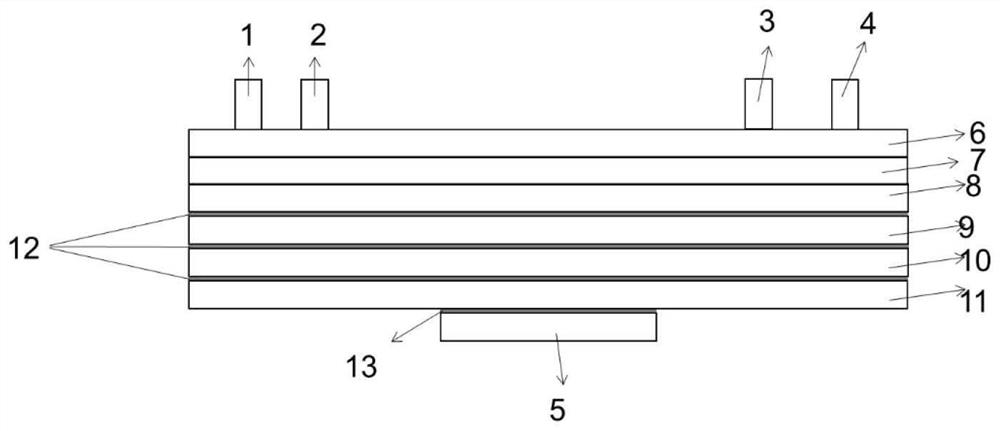

A vertical channel tunable high-throughput acoustofluidic sorting chip and its preparation method

A vertical channel, high-throughput technology, applied in the field of micro-total analysis, can solve the problems of unfavorable life safety of experimenters, increase of preparation cost, low sorting flux, etc., to achieve improved fluid flux, low cost, and large application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of high-throughput acoustofluidic sorting chip

[0063] The preparation method is as follows:

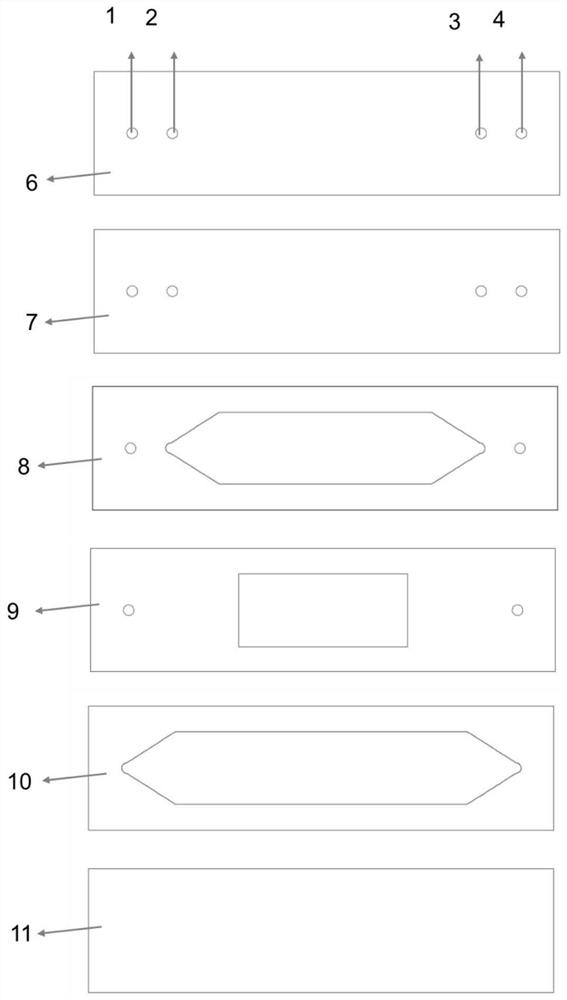

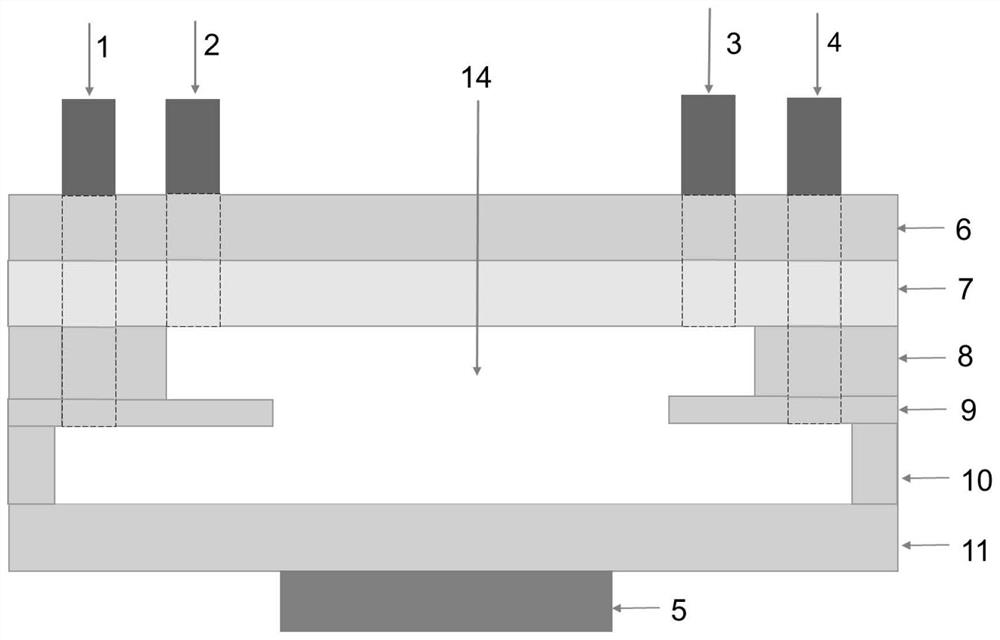

[0064] (1) Prepare 5 pieces of glass sheets and PDMS film 7, wherein the glass sheets include bottom sheet 11, gasket I 10, spacer I 9, gasket II 8, and top sheet 6;

[0065] (2) Use laser cutting glass sheets with different thicknesses to process 5 glass sheets with the same overall size and hollow shape;

[0066] Negative film 11 with a thickness of 1.25 mm;

[0067] Gasket I 10, with a hexagonal hollow in the middle and a thickness of 200 μm;

[0068] The middle of the spacer I 9 is hollowed out into a square, and the thickness is 75 μm;

[0069] Spacer II 8 has a hexagonal hollow in the middle, which is exactly the same as Spacer I 10 on the whole, with a thickness of 200 μm;

[0070] PDMS film 7 with a thickness of 200 μm;

[0071] Top sheet 6 with a thickness of 1.25 mm;

[0072] Among them, the size of the hollow area: gasket I > gasket II > spacer I;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com