Modified lignin as well as preparation method thereof and application of modified lignin in phenolic resin adhesive

A lignin and modification technology, applied in the field of materials, can solve the problem of high process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

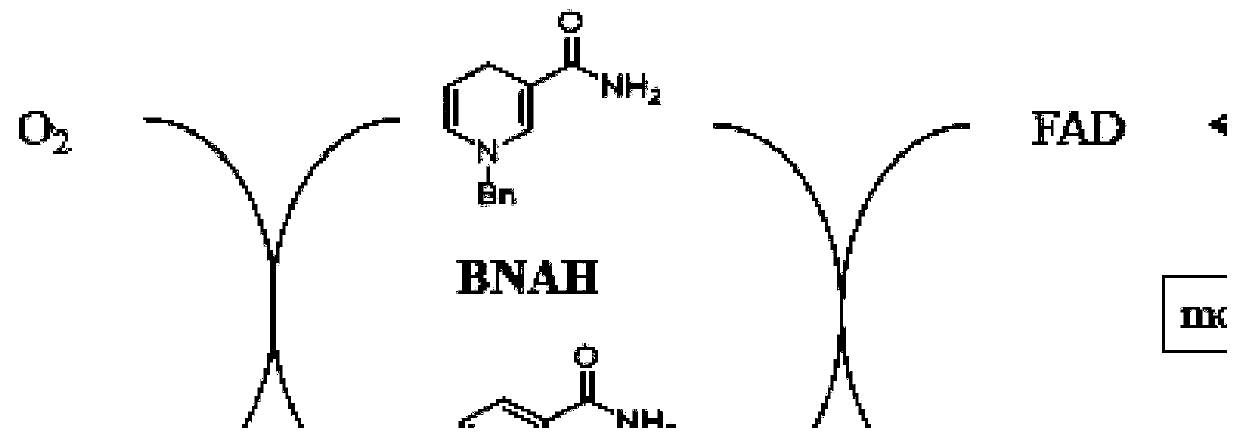

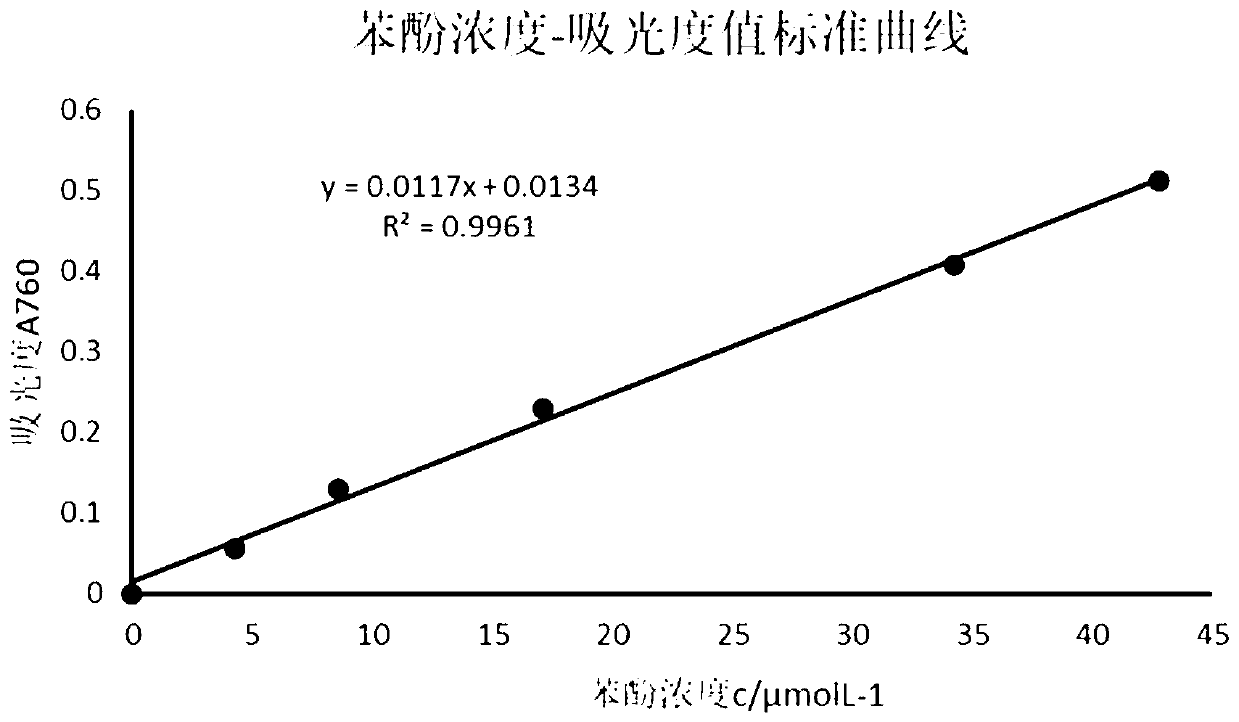

[0063] In 10 mL of 50 mM pH 6.0 potassium phosphate buffer, 0.05 g of alkali lignin, 0.1 mM of FAD, 5 mM of BNAH were added, and finally 30 U / mL of phenol monooxygenase was added. Put it in a shaker at 30°C and 200rpm to react, and the reaction liquid is communicated with the outside air. After reacting for 12 hours, filter the reaction solution, wash it with water until neutral, dry it in a vacuum oven at 80°C to constant weight, obtain hydroxylated modified lignin after drying, weigh the product, and the yield is 76%, unmodified alkali lignin The phenolic hydroxyl content was 2.66%, the hydroxylated lignin phenolic hydroxyl content was 4.22%, and the phenolic hydroxyl content increased by 1.56%.

Embodiment 2

[0065]

[0066] In 20mL water, add alkali lignin 0.2g, FAD 0.2mM, C 10 h 16 N 2 O 10mM, finally add phenol monooxygenase 40U / mL. Put it in a shaker at 30°C and 150rpm to react, and the reaction liquid is connected with the outside air. After reacting for 12 hours, the reaction solution was filtered, washed until neutral, and dried in a vacuum oven at 80°C to constant weight. After drying, the hydroxylated modified lignin was obtained, and the product was weighed. The yield was 80%, and the unmodified alkali lignin The content of the phenolic hydroxyl group in the base is 2.66%, the content of the hydroxylated modified lignin is 4.44%, and the content of the phenolic hydroxyl group increases by 1.78%.

Embodiment 3

[0068]

[0069] In 30mL of 50mM pH 7.0 potassium phosphate buffer, add lignosulfonate 0.6g, FAD 0.5mM, C 11 h 18 N 2 O 50mM, finally add phenol monooxygenase 50U / mL. Put it at 40°C and react in a shaker at 200 rpm, and the reaction solution is connected to the outside air. After reacting for 15 hours, the reaction solution was filtered, washed until neutral, and dried in a vacuum oven at 80°C to constant weight. After drying, the hydroxylated modified lignin was obtained, and the product was weighed. The yield was 82%, and the unmodified lignin The phenolic hydroxyl content of sulfonate was 2.32%, the hydroxylated lignin phenolic hydroxyl content was 4.92%, and the phenolic hydroxyl content increased by 2.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com