Novel environment-friendly mixed type plastic runway

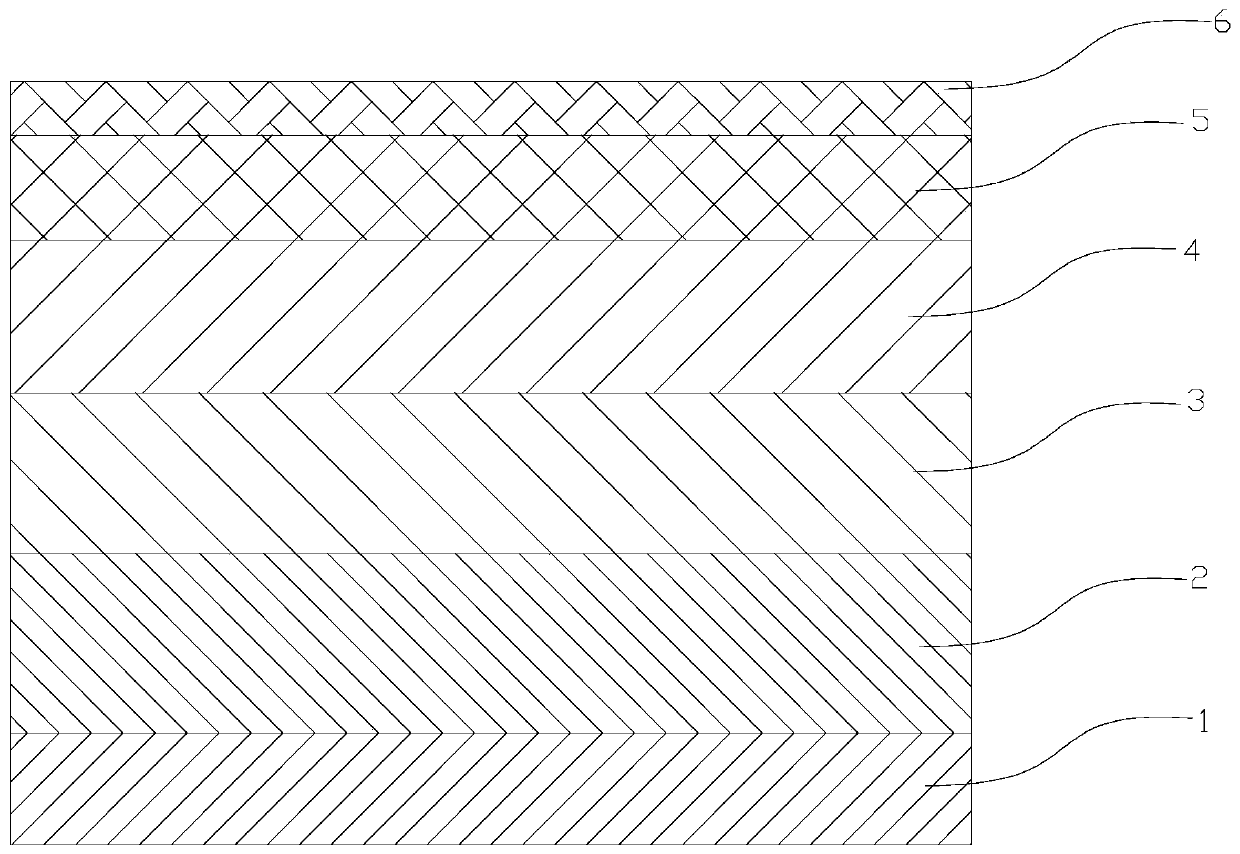

A plastic runway and hybrid technology, applied in the field of runways, can solve problems such as runway cracking, increased gaps, and reduced connection strength, and achieve good water permeability, high frictional strength, and strong compression and deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] S1: pour a layer of cement mortar pouring layer with a thickness of 5cm on the mud floor;

[0055] S2: Stir and mix 30 parts of cement, 24 parts of sand, 10 parts of pumice, 2 parts of activated carbon powder, 2 parts of alumina powder, 1 part of copper powder, 2 parts of polypropylene fiber with water, and spread it on the cement mortar pouring layer , and then compacted into a pre-laid layer, controlling the thickness of the entire pre-laid layer to be 4-5cm;

[0056] S3: Mix and stir 35 parts of polyurethane glue, 15 parts of spherical rubber particles, 2 parts of nano-silica particles, 3 parts of talc powder, 7 parts of drier, and 15 parts of square silica gel particles, and then spread to the pre- On the laying layer, it is compacted into a base layer, and the thickness of the base layer is controlled to be 2.9-3.1cm;

[0057] S4: Mix 100 parts of polyurethane glue, 150 parts of rubber granules, and 20 parts of ceramsite evenly together, then spread them on the ba...

Embodiment 2

[0061] The steps of this example are carried out with reference to the examples, and the components of each step are proportioned according to the following

[0062] Pre-laying layer: 35 parts of cement, 26 parts of sand, 15 parts of pumice, 2 parts of activated carbon powder, 2 parts of alumina powder, 1 part of copper powder, 2 parts of polypropylene fiber, and the balance is water;

[0063] Base layer: 40 parts of polyurethane glue, 20 parts of spherical rubber particles, 2 parts of nano-silica particles, 4 parts of talcum powder, 7 parts of drier, 15 parts of square silica gel particles;

[0064] Reinforcement layer: 120 parts of polyurethane glue, 150 parts of rubber particles, 20 parts of ceramsite;

[0065] Surface layer: 4 parts of EPDM particles, 13 parts of self-knotting finish paint, 1 part of quartz sand, 0.05 parts of cork particles.

Embodiment 3

[0067] Pre-laying layer: 40 parts of cement, 30 parts of sand, 15 parts of pumice, 2 parts of activated carbon powder, 2 parts of alumina powder, 1 part of copper powder, 3 parts of polypropylene fiber, and the balance is water;

[0068] Base layer: 45 parts of polyurethane glue, 25 parts of spherical rubber particles, 1 part of nano-silica particles, 3 parts of talcum powder, 7 parts of drier, 25 parts of square silica gel particles;

[0069] Reinforcement layer: 100 parts of polyurethane glue, 160 parts of rubber particles, 25 parts of ceramsite;

[0070] Surface layer: 4 parts of EPDM particles, 13 parts of self-knotting finish paint, 1 part of quartz sand, and 1 part of cork particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com