Method for detecting nickel content in acid etching waste liquid

A technology of acid etching waste liquid and detection method, which is applied in the measurement of color/spectral characteristics, measurement device, preparation of test samples, etc., can solve problems such as affecting the determination of nickel impurity content, and achieve the effect of removing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the embodiment of the present invention, the acidic etching waste liquid used in one of the etching processes in the printed circuit board (PCB) is selected, and the copper content in the used acidic etching waste liquid is about 120 g / L.

[0031] A detection method for nickel content in acidic etching waste liquid, comprising the steps of:

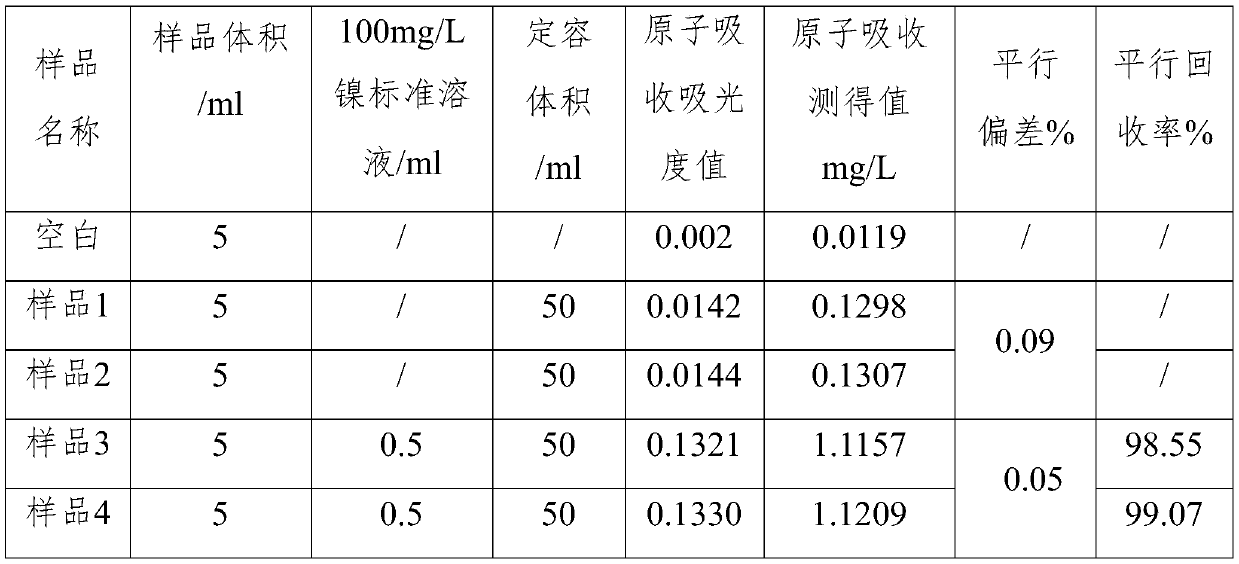

[0032] (1) Accurately pipette 4 parts of 5ml acidic etching waste liquid, each part of acidic etching waste liquid is pipetted into a 50ml beaker; 4 parts of acidic etching waste liquid are respectively recorded as sample 1, sample 2, sample 3 and sample 4 ;

[0033] (2) each adding 0.5ml concentration is the nickel standard solution of 100mg / L in the beaker that sample 3 and sample 4 place;

[0034] (3) in each beaker, all add 3g potassium iodide, shake up and dissolve, the sample in each beaker is constant volume in a 50ml volumetric flask, after the sample in the volumetric flask is shaken up, filter and remove the cuprous i...

Embodiment 2

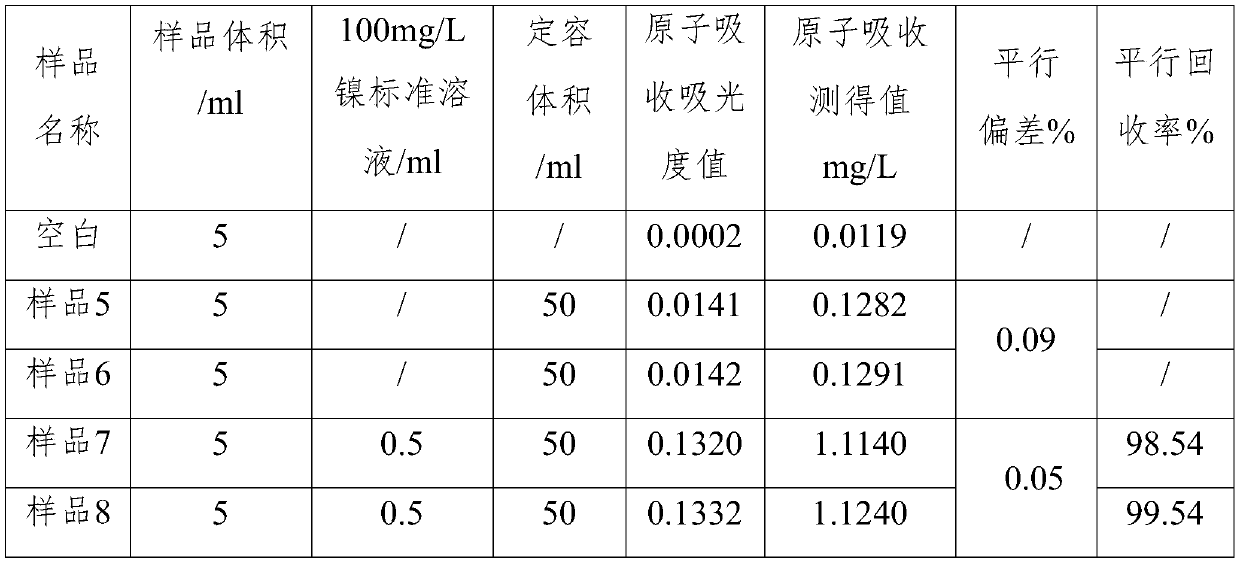

[0041] In the embodiment of the present invention, the acidic etching waste liquid used in another etching process in the printed circuit board (PCB) is selected, and the copper content in the used acidic etching waste liquid is about 125 g / L.

[0042] A detection method for nickel content in acidic etching waste liquid, comprising the steps of:

[0043] (1) Accurately pipette 4 parts of 5ml acidic etching waste liquid, each part of acidic etching waste liquid is pipetted into a 50ml beaker; 4 parts of acidic etching waste liquid are respectively recorded as sample 1, sample 2, sample 3 and sample 4 ;

[0044] (2) each adding 0.5ml concentration is the nickel standard solution of 100mg / L in the beaker that sample 3 and sample 4 place;

[0045] (3) in each beaker, all add 3g potassium iodide, shake up and dissolve, the sample in each beaker is constant volume in a 50ml volumetric flask, after the sample in the volumetric flask is shaken up, filter and remove the cuprous iodide...

Embodiment 3

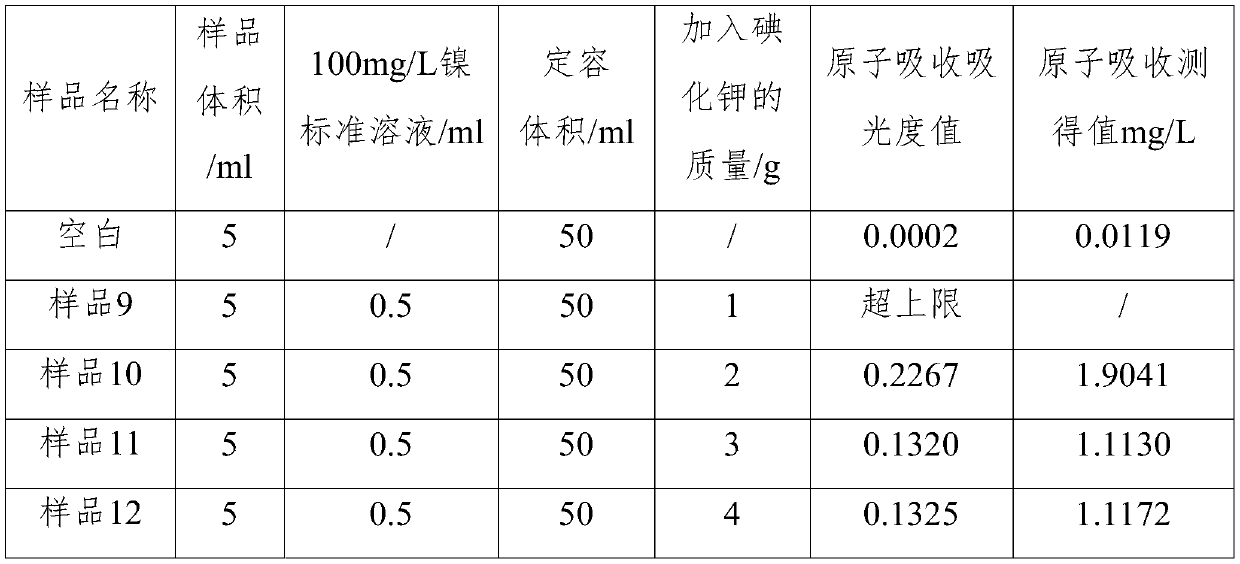

[0052] The addition of potassium iodide is confirmed by the following steps:

[0053] (1) Accurately pipette 5ml of acidic etching waste liquid in 4 parts of implementation case 1 in 4 beakers of 50ml, and add 0.5ml content respectively to be the nickel standard solution of 100mg / L, 4 parts of samples are respectively marked as sample 9, Sample 10, Sample 11, Sample 12;

[0054](2) Weigh 1g, 2g, 3g, and 4g of potassium iodide in the sample 9-12 in turn, add a small amount of pure water to dissolve, shake well, transfer to a 50ml volumetric flask after the reaction is complete, and dilute to constant volume;

[0055] (3) Filter the above 4 samples to obtain the clear solution, and detect the nickel content at a wavelength of 232nm with an atomic absorption spectrophotometer under a hollow cathode lamp according to the detection standard of the national standard GB / T9723-2007. At the same time, pure water was taken as a blank group to detect nickel content at a wavelength of 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com