Production line equipment and preparation method of high-density mineral wool fiberboard

A technology of mineral wool fiber and production line equipment, which is applied in glass manufacturing equipment, manufacturing tools, and feeding of melting furnaces, etc. It can solve the problems of bamboo and wood resources, unfavorable ecological environment protection, poor fire resistance, and sewage generation, and achieve good fire resistance. , High tensile and compressive strength, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

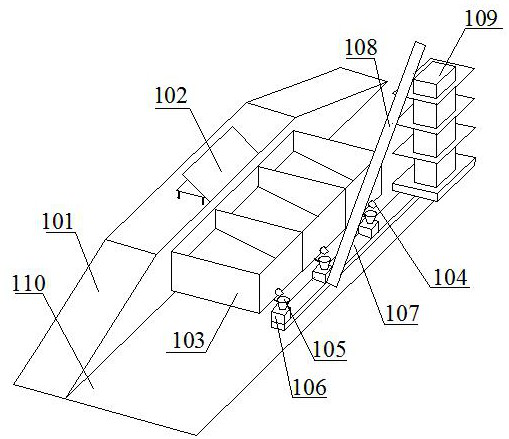

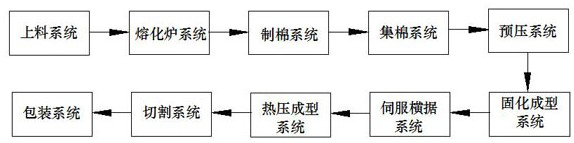

[0046] A production line equipment for high-density mineral wool fiberboard, including a feeding system and a melting furnace system;

[0047] The feeding system includes a working platform 110, a side end surface of the working platform 110 is provided with a vertically arranged rollover vehicle walking platform 101, and the cross section of the rollover vehicle running platform 101 is that the two waists are inclined planes. Trapezoidal, or isosceles trapezoidal, the end surface of the rollover vehicle walking platform 101 is provided with a rollover vehicle 102 that moves laterally along its end surface, and the side of the side of the rollover vehicle running platform 101 horizontal section on the working platform is correspondingly arranged There are several material bins 103 for receiving different types of raw materials. The material bins 103 are arranged parallel to each other. The walking platform 101 of the rollover vehicle is higher than the material bins 103. Warehou...

Embodiment 2

[0077] A production line equipment for high-density mineral wool fiberboard, including a feeding system and a melting furnace system;

[0078] The feeding system includes a working platform 110, a side end surface of the working platform 110 is provided with a vertically arranged rollover vehicle walking platform 101, and the cross section of the rollover vehicle running platform 101 is that the two waists are inclined planes. Trapezoidal, also can be isosceles trapezoidal, described rollover car walking platform 101 end face is provided with the rollover car 102 that moves laterally along its end face, is positioned at the side of the side of rollover car running platform 101 horizontal sections on the working platform Several material bins 103 for receiving different types of raw materials, the material bins 103 are arranged parallel to each other, the walking platform 101 of the rollover vehicle is higher than the material bin 103, and the hopper of the rollover vehicle 102 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com