A production process of glue-free and formaldehyde-free fiberboard with co-production of fulvic acid from straw

A production process, the technology of fulvic acid, is applied in fiber raw material processing, wood processing appliances, and other household appliances, etc. It can solve the problems not involved in the sewage treatment of the production of glue-free and formaldehyde-free fiberboard, and achieve economic value and product added value High, improve industrial competitiveness, eliminate pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Use wheat straw as raw material, crush it to 2-5cm for later use, follow the steps below:

[0080] The first step, washing materials;

[0081] In the second step, preliminary purification, activation and saccharification are carried out by cooking. Dosing and dosing according to the following ratio: 2 tons of absolute dry raw materials, 200kg of ammonium sulfite, add water according to the liquid ratio of 1:5, put into steaming balls, heat to 120°C to release steam, heat up to 160°C, keep warm for 60min, and discharge. The initial purification, activation and saccharification are completed by cooking, which not only degrades non-wood fiber components such as pectin wax into low sugar and dissolves them in the cooking liquid, partially degrades hemicellulose, saccharifies and dissolves them in the cooking liquid; at the same time, makes part of the lignin sulfonate It can be activated by chemical hydrolysis, splitting lignin as a whole and separating it from cellulose; ...

Embodiment 2

[0100] Use cotton stalks as raw materials, crush them to 2-5cm for later use, and proceed as follows:

[0101] The first step, washing materials;

[0102] In the second step, preliminary purification, activation and saccharification are carried out by cooking. Dosing and dosing according to the following proportions: 1kg of absolute dry raw material, 200g of ammonium sulfite, add water according to the liquid ratio of 1:5, put it into a 15L electric heating rotary steamer, heat to 120°C to release steam, heat up to 160°C, keep it warm for 60min, and leave material. The initial purification and activation are completed by cooking, which not only degrades non-wood fiber components such as pectin wax into low sugar and dissolves them in the cooking liquid, partially degrades hemicellulose, saccharifies and dissolves them in the cooking liquid; at the same time, makes part of the lignin sulfonated and hydrolyzed Thus, it can be activated, and the whole lignin can be split and se...

Embodiment 3

[0118] Cotton stalks are used as raw materials.

[0119] Step 1~step 7 are the same as embodiment 2;

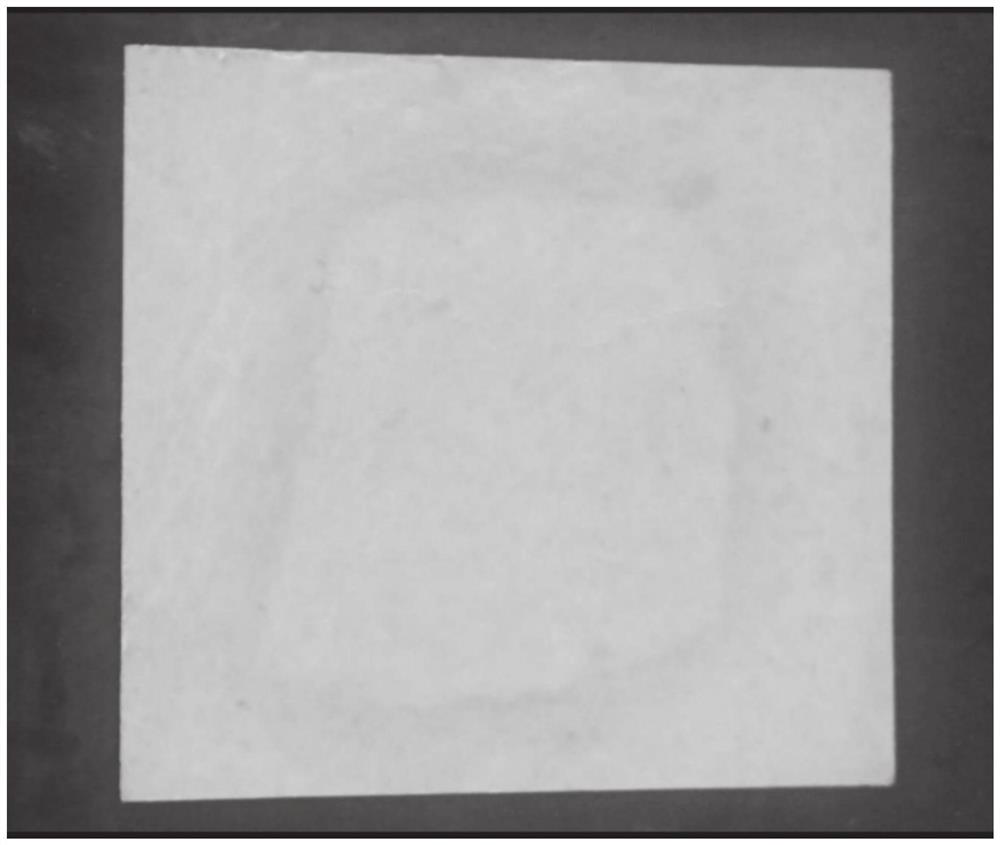

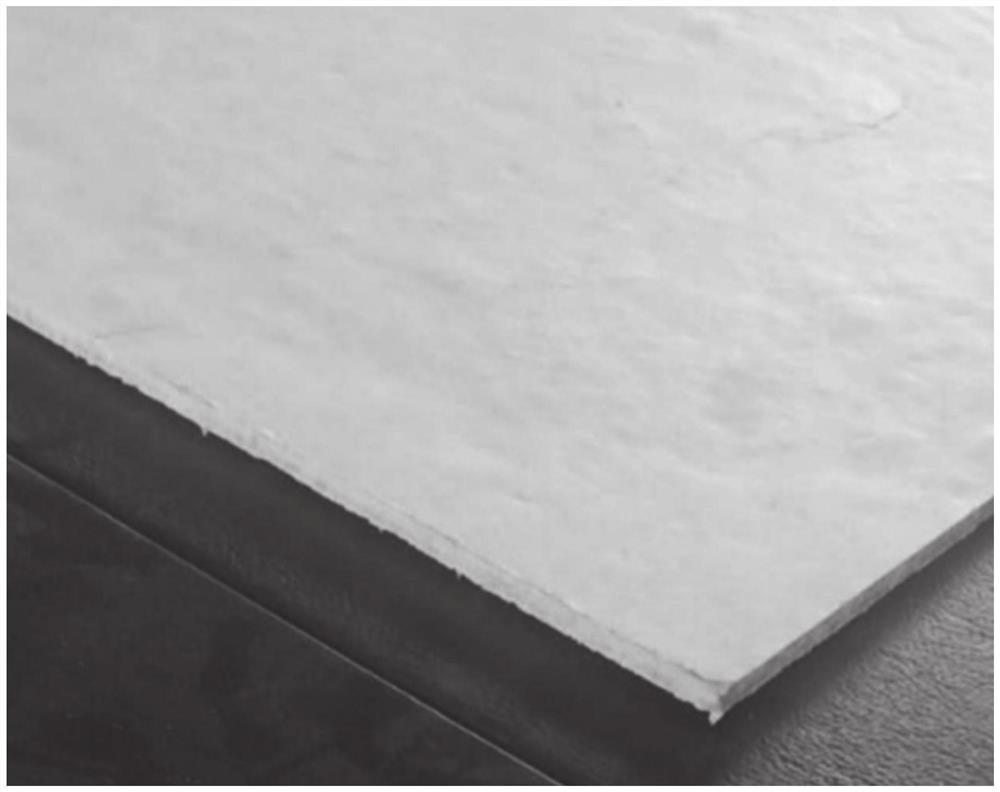

[0120] Step 8, board making and testing indicators.

[0121] Experimental conditions: SYD1 test hot press——produced by Shanghai Liangjun Hydraulic Equipment Co., Ltd. The test adopts the flat pressing method. Take 1 kg of cotton stalk purified fiber pulp with absolute dry weight, 400 g of fulvic acid black liquor, and 20 g of paraffin. Quantity 15%, stir evenly in a glue blender, set aside. Make a density board with a size of 300mm*300mm and a thickness of 3mm. The hot pressing pressure is 4 MPa, the hot pressing temperature is 200°C, and the hot pressing time is 10 minutes.

[0122] Detection Indicator:

[0123]

[0124] The main indicators meet or exceed the ordinary type standard of GB / T 31765-2015 "High Density Fiberboard".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com