Wire-cutting enameling style plant specimen handicraft making method

A technology of plant specimens and production methods, applied in botanical equipment and methods, techniques for producing decorative surface effects, preservation of plants, etc., can solve the problems of not being able to use the natural texture of plants, etc., achieve flexibility in texture, and meet high temperature resistance Firing, the effect of enhancing artistic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: prepare the herbarium handicraft of the cloisonné enamel style as follows:

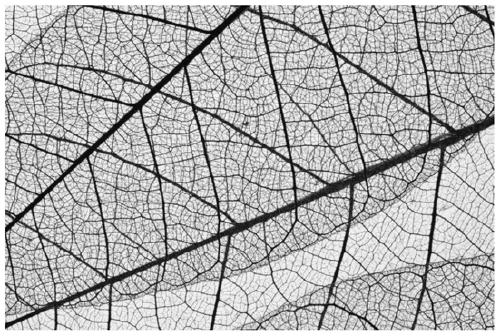

[0035] (1) Preparation of plant veins: the plant leaves are boiled with 12wt% sodium hydroxide aqueous solution for 30 minutes, and then the water flow washes away the leaf pulp, and the remaining complete veins are blotted dry with absorbent paper for subsequent use, such as image 3 shown;

[0036] (2) Treat the plant leaf veins with glycerin and aloe gel infiltration for flexibility or directly soak in calcium bicarbonate solution for hardening; when the plant tissue is hard, such as old leaves, use glycerin and aloe gel to infiltrate for flexibility, as follows : Mix glycerin and aloe vera gel according to the ratio of 1:5 and use it as a flexible solution, immerse the veins in the flexible solution for 12 hours, take it out, rinse it with water, and dry it with absorbent paper; when the plant tissue is tender, such as young leaves or petals, directly Soak in calcium bicarbon...

Embodiment 2

[0046] Embodiment 2: prepare the herbarium handicraft of the cloisonné enamel style as follows:

[0047] (1) Preparation of plant veins: the plant leaves were boiled for 60 minutes with 12wt% calcium hydroxide aqueous solution, and then washed with water to remove the mesophyll, and the remaining complete veins were blotted dry with absorbent paper for subsequent use;

[0048] (2) Plant leaf veins are infiltrated and flexibly treated with glycerin and aloe vera gel or directly soaked in calcium bicarbonate solution for hardening treatment, the method is the same as in Example 1.

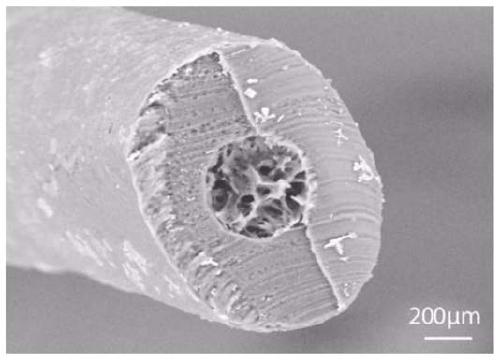

[0049] (3) adopt polyacrylonitrile to hang film on leaf vein, concrete steps are as follows:

[0050] (A) Preparation of polyacrylonitrile membrane-hanging solution: fully dissolve the completely dehydrated polyacrylonitrile membrane in DMF, add a thickener and stir fully, the solution is filtered, vacuum standing state defoaming to obtain the membrane-hanging solution, The mass concentration of the...

Embodiment 3

[0058] Embodiment 3: prepare the herbarium handicraft of the cloisonné enamel style as follows:

[0059] (1) Preparation of plant veins: use 12wt% calcium hydroxide aqueous solution to boil for 50 minutes, then wash to remove the mesophyll, and absorb the remaining complete veins with absorbent paper for subsequent use;

[0060] (2) Plant leaf veins are infiltrated and flexibly treated with glycerin and aloe vera gel or directly soaked in calcium bicarbonate solution for hardening treatment, the method is the same as in Example 1.

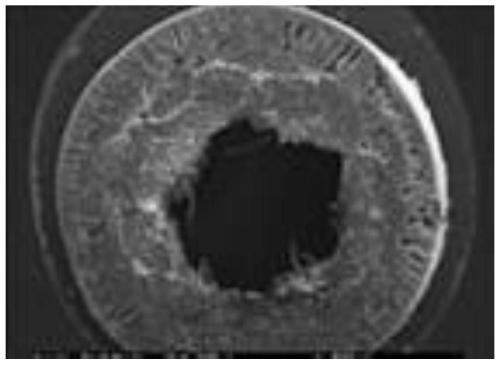

[0061] (3) adopt polyacrylonitrile to hang film on leaf vein, concrete steps are as follows:

[0062] (A) Preparation of polyacrylonitrile membrane-hanging solution: fully dissolve the completely dehydrated polyacrylonitrile membrane in DMSO, fully stir after adding a thickener, filter the solution, and defoam in a vacuum state to obtain a membrane-hanging solution. The mass concentration of the polyacrylonitrile film in the film-hanging solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com