Plant functional polyester fibers and preparation method thereof

A polyester fiber and functional technology, which is applied in the field of plant functional polyester fiber and its preparation, can solve problems such as single function, hidden safety hazards, and complicated production, and achieve multi-function, outstanding performance, and simple and easy methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

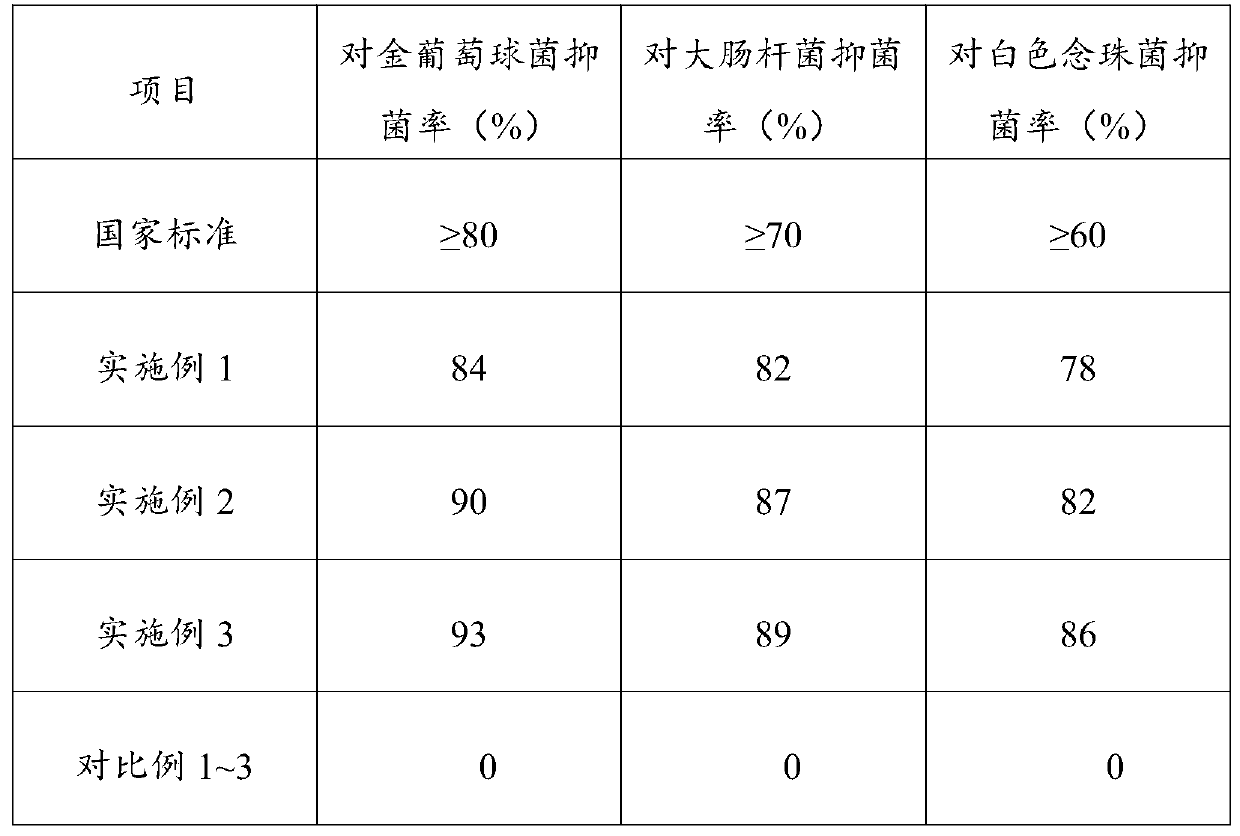

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of plant functional polyester fiber, comprises the following steps:

[0020] mixing plant powder and polyester powder, and sequentially melt-blending, extruding, granulating and drying the obtained mixture to obtain plant functional masterbatch;

[0021] The plant functional masterbatch and the polyester chip are blended and spun to obtain the plant functional polyester fiber.

[0022] In the present invention, unless otherwise specified, the required raw materials are commercially available products well known to those skilled in the art.

[0023] In the invention, plant powder and polyester powder are mixed, and the obtained mixture is sequentially melt-blended, extruded, granulated and dried to obtain plant functional masterbatch. In the present invention, the preparation process of the plant powder preferably includes: crushing and ultrafine pulverizing the plants in sequence to obtain the plant powder. In the pr...

Embodiment 1

[0036] 10 kg of dried mint leaves were crushed to 80 meshes, and then ultrafinely pulverized. During the ultrafine pulverization process, 12 kg of dry ice was added, and the pulverization time was 45 minutes to obtain 8 kg of mint powder with an average particle size of 0.5 μm.

[0037] Dry the PET powder in a vacuum oven at 120°C for 4 hours to make the moisture content reach 300ppm, then mix 8kg of dried PET powder with 2kg of mint powder, and use a twin-screw extruder to obtain the mixture Melt blending, extrusion and granulation, and after drying, plant functional masterbatches are obtained;

[0038] After the PET slices are dried until the water content reaches 300ppm, the plant functional masterbatch is added to the dried PET slices to form a mixture with a volume metering injection machine, so that the content of the plants is 1% of the total weight of the mixture. %, the mixture is blended and spun to obtain plant functional polyester fibers.

Embodiment 2

[0042] 10 kg of dried Radix isatidis leaves were pulverized to 90 mesh, and then ultrafinely pulverized. During the ultrafine pulverization, 11 kg of dry ice was added, and the pulverization time was 30 minutes to obtain 9 kg of Radix isatidis powder with an average particle size of 3 μm.

[0043] Dry the PBT powder in a vacuum oven at 120°C for 4 hours to make the moisture content reach 300ppm, then mix 8.5kg of the dried PBT powder and 1.5kg of Radix Radix Radix, and extrude the obtained mixture by twin-screw machine for melt blending, extrusion and granulation, and after drying, plant functional masterbatches are obtained;

[0044]After the PBT slices are dried until the water content reaches 300ppm, the plant functional masterbatch is added to the dried PET slices with a volume metering injection machine to form a mixture, so that the content of the plants is 2% of the total weight of the mixture. %, the mixture is blended and spun to obtain plant functional polyester fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com