Battery back silicon nitride film layer, PERC battery and preparation method

A front-side silicon nitride film and silicon nitride film technology, used in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high temperature requirements for the production process of the back film, low reflectivity of the battery back film, and low battery conversion efficiency. , to achieve the effect of improving the passivation effect, obvious advantages of current performance, and reducing the annealing time of the back film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment takes P-type monocrystalline silicon as an example to describe the five-layer structure of its PERC solar cell back film and the corresponding low-temperature preparation method.

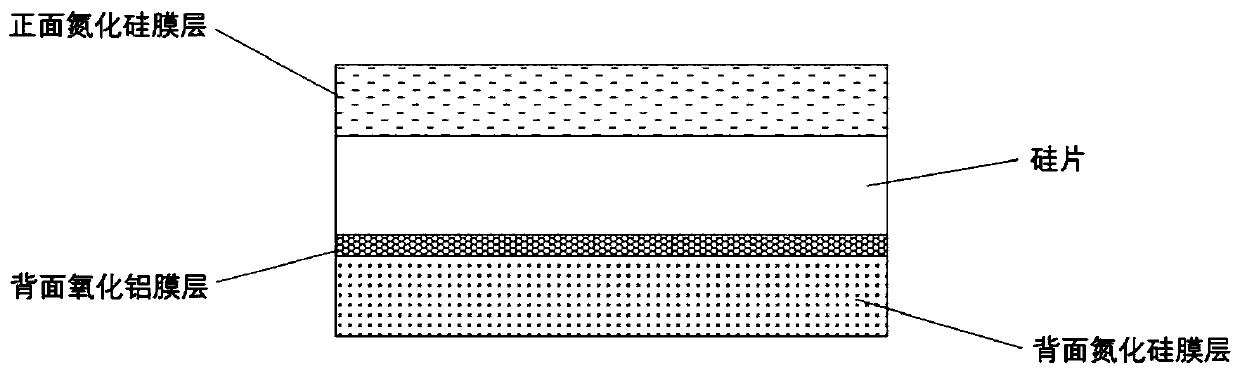

[0041] First of all, the battery structure of the present invention is as follows figure 1 As shown, the front side of the monocrystalline cell is coated with a front silicon nitride film layer to reduce reflection. It plays a protective role, and at the same time increases the reflectivity of the back, obtains a better passivated surface, and improves the conversion efficiency of the battery.

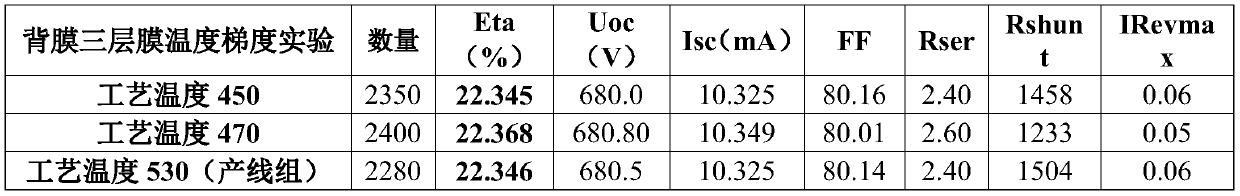

[0042] Table 1

[0043] Silicon nitride film on the back film thickness Refractive index level one 25nm±5nm 2.6±0.2 Second floor 10nm±5nm 2.1±0.1 the third floor 30nm±5nm 2.5±0.1 fourth floor 20nm±5nm 2.3±0.05 fifth floor 45nm±5nm 2.1±0.1

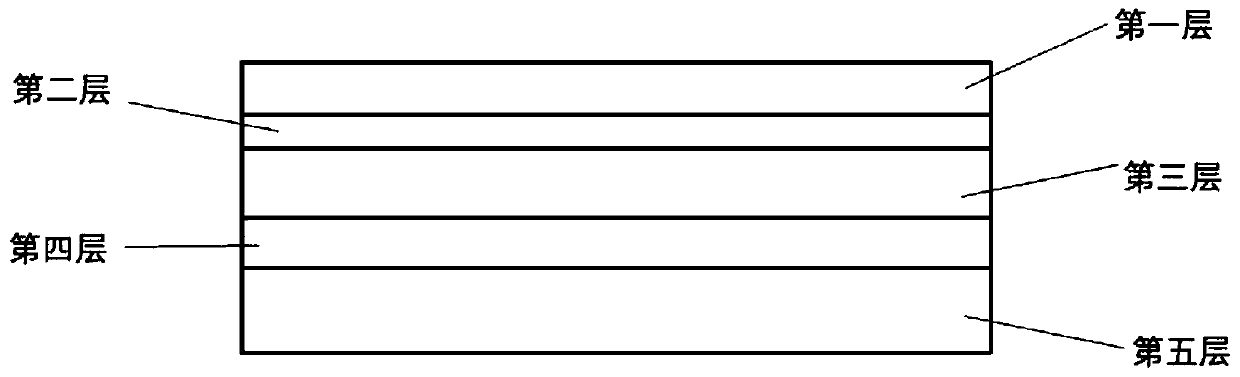

[0044] Such as figure 2 As shown, the silicon nitride film layer on the back side of ...

Embodiment 2

[0048] The five-layer structure battery with the back film described in Example 1, the specific manufacturing steps are as follows:

[0049] Step Ⅰ: Obtain pre-treated silicon wafers through texturing, diffusion, primary annealing, etching and secondary annealing operations;

[0050] a), cashmere:

[0051] Carry out isotropic etching with acid solution to obtain a surface structure with many pits on the surface, and at the same time play a good role in light trapping. Texture processing is carried out on monocrystalline silicon wafers to form a pyramid textured surface, so that the surface of the silicon wafer is formed uniformly. The pyramid-like structure enhances light absorption and improves the short-circuit current and conversion efficiency of the battery.

[0052] The reaction equation is: Si+4HNO 3 +6HF=H 2 SiF 6 +4NO 3 +4H 2 O.

[0053] b) Diffusion to prepare PN junction:

[0054] Surface phosphorus source propulsion, using thermal propulsion to form PN junct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com