Alfentanil pharmaceutical composition for transdermal administration as well as preparation method and application of pharmaceutical composition

A technology for transdermal drug delivery and composition, which is applied in the field of alfentanil transdermal drug drug composition and its preparation, which can solve the problems of poor compliance and inconvenient medication for patients, and achieve the effect of improving transdermal permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The transdermal patch preparation of embodiment 1 alfentanil hydrochloride

[0068] (1) 3 g of alfentanil hydrochloride, 2 g of povidone (PVP-S630) and 0.15 g of magnesium stearate are micronized, mixed uniformly to obtain a physical mixture, and 4.85 g of polyethylene glycol (molecular weight 2000) is added;

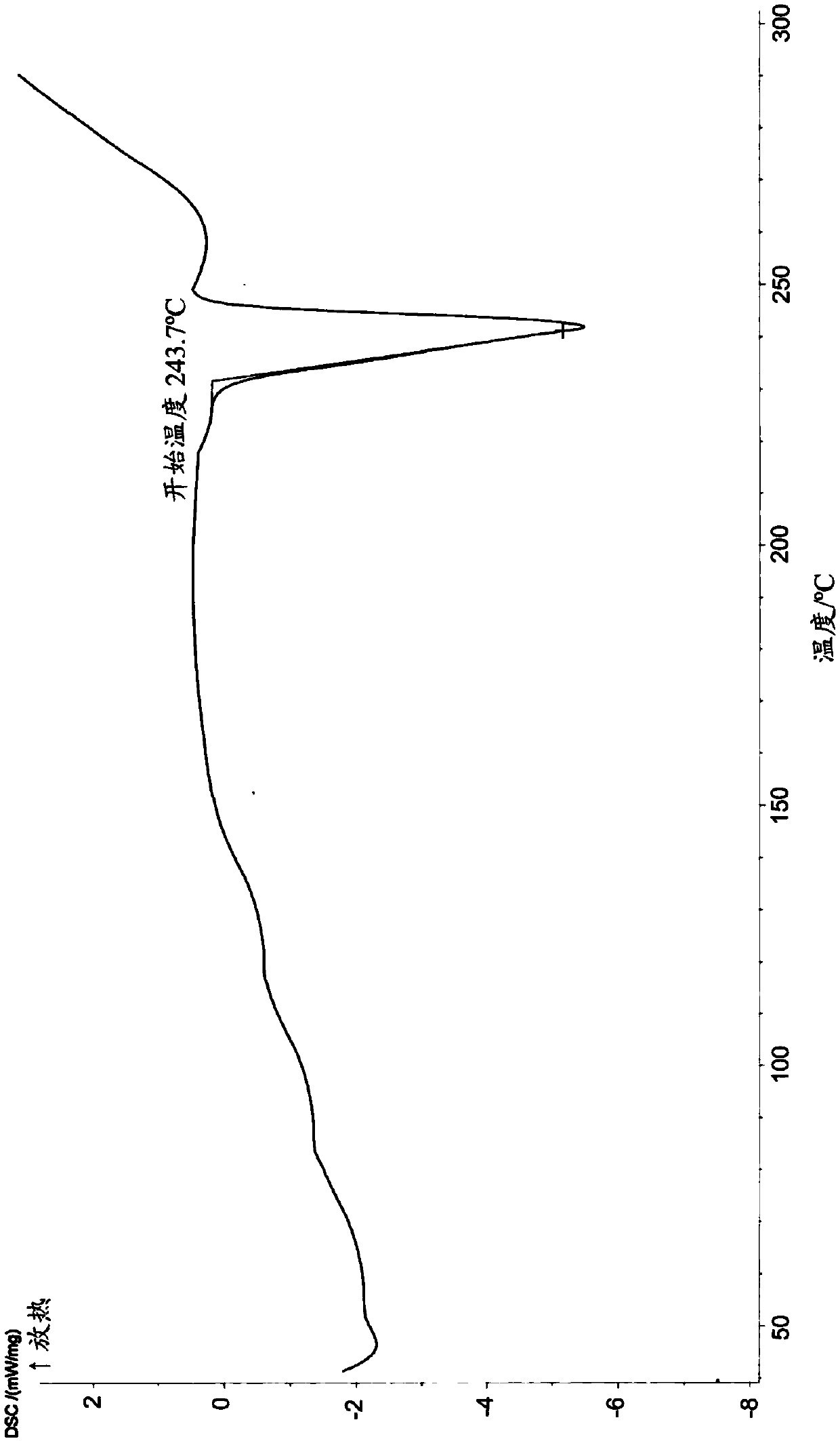

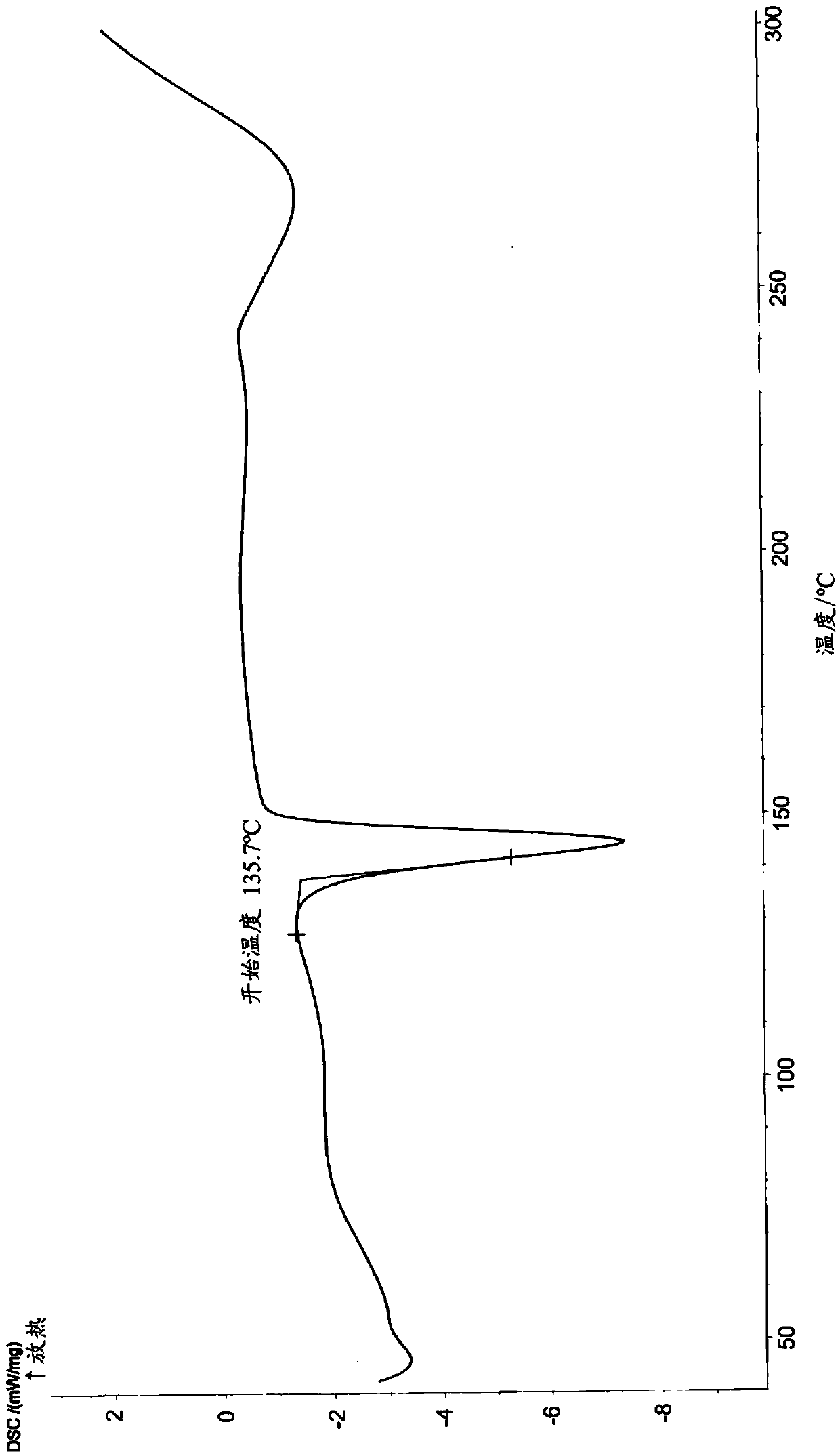

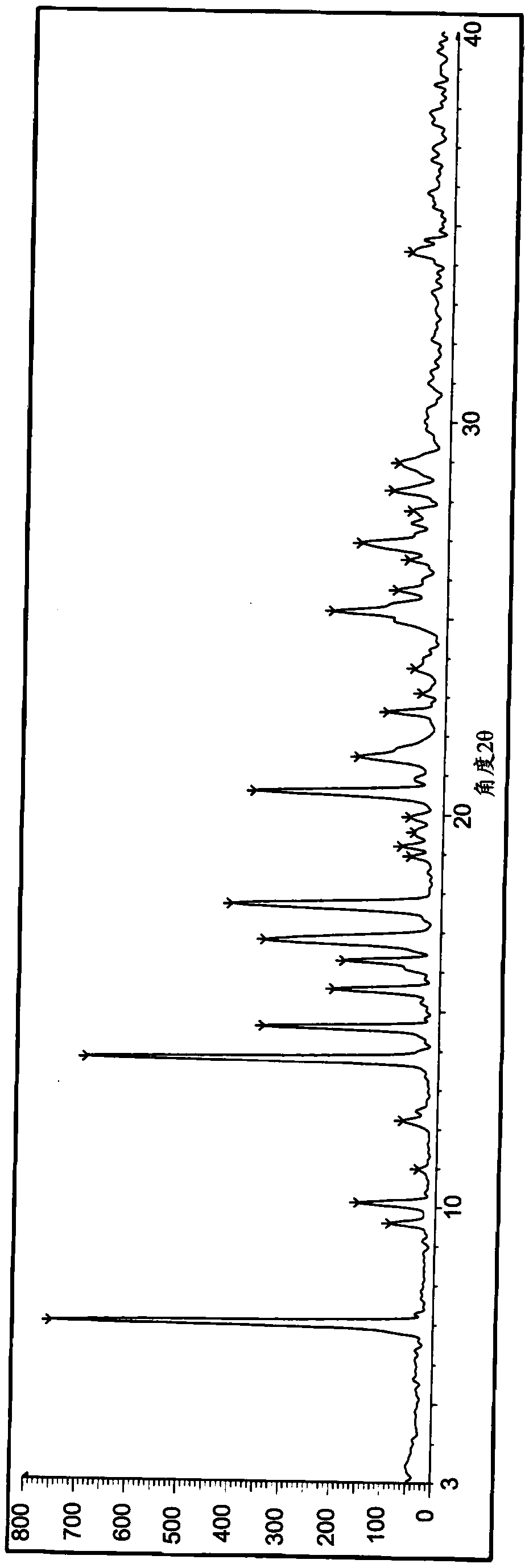

[0069] (2) Set the extrusion temperature of the twin-screw extruder to 120°C, start the screw after rising to the set temperature, add the physical mixture in step (1) to the extruder, heat-melt and extrude, It is extruded in the form of spherical particles to obtain amorphous particles, which are then micronized, and the particle size is controlled at about 100-150nm.

[0070] (3) Weighing 0.5 g of micronized amorphous particles prepared in step (2), 0.2 g of soybean lecithin, 0.03 g of cholesterol, 3 g of absolute ethanol, and 6.27 g of water;

[0071] (4) Dissolving soybean lecithin, cholesterol, and alfentanil hydrochloride particles in absolute ethanol, hea...

Embodiment 2

[0075] The transdermal patch preparation of embodiment 2 alfentanil hydrobromide

[0076] (1) Micronize 3 g of alfentanil hydrobromide, 1.5 g of povidone (PVP-S630), and 0.1 g of talcum powder, mix well to obtain a physical mixture, and add 5.4 g of polyethylene glycol (molecular weight 3000) ;

[0077] (2) Set the extrusion temperature of the twin-screw extruder to 100°C, start the screw after rising to the set temperature, add the physical mixture in step (1) to the extruder, heat-melt and extrude, It is extruded in the form of spherical particles to obtain amorphous particles, which are then micronized, and the particle size is controlled at about 150-200nm.

[0078] (3) Weigh 0.3 g of micronized amorphous particles prepared in step (2), 0.2 g of phosphatidylcholine, 0.08 g of cholesterol, 3 g of propylene glycol, and 6.42 g of water;

[0079] (4) Dissolving phosphatidylcholine, cholesterol, and alfentanyl hydrobromide microparticles in propylene glycol, and heating to 30...

Embodiment 3

[0083] The transdermal patch preparation of embodiment 3 alfentanil tosylate

[0084] (1) Micronize 0.5 g of alfentanil tosylate, 4 g of povidone (PVP-VA64), and 0.1 g of magnesium stearate, mix well to obtain a physical mixture, add polyethylene glycol (molecular weight 4000) 5.4g;

[0085] (2) Set the extrusion temperature of the twin-screw extruder to 140°C, start the screw after rising to the set temperature, add the physical mixture in step (1) to the extruder, heat-melt and extrude, It is extruded in the form of spherical particles to obtain amorphous particles, which are then micronized, and the particle size is controlled at about 250-300nm.

[0086] (3) Weigh 6 g of micronized amorphous particles prepared in step (2), 2 g of dipalmitoylphosphatidylcholine, 0.3 g of cholesterol, 24 g of absolute ethanol, and 67.7 g of water;

[0087] (4) Dissolving dipalmitoylphosphatidylcholine, cholesterol, and alfentanyl tosylate microparticles in absolute ethanol, and heating to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com