Anti-scaling plastic pipe with far infrared radiation function and preparation method thereof

A technology for far-infrared radiation and plastic pipes is applied in the field of anti-scaling plastic pipes and their preparation, which can solve the problems of affecting the health and comfort of radiant floor heating, waste of energy in radiant floor heating, affecting the heating temperature and effect, etc., so as to improve the heating effect. Efficiency, not easy to scale, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

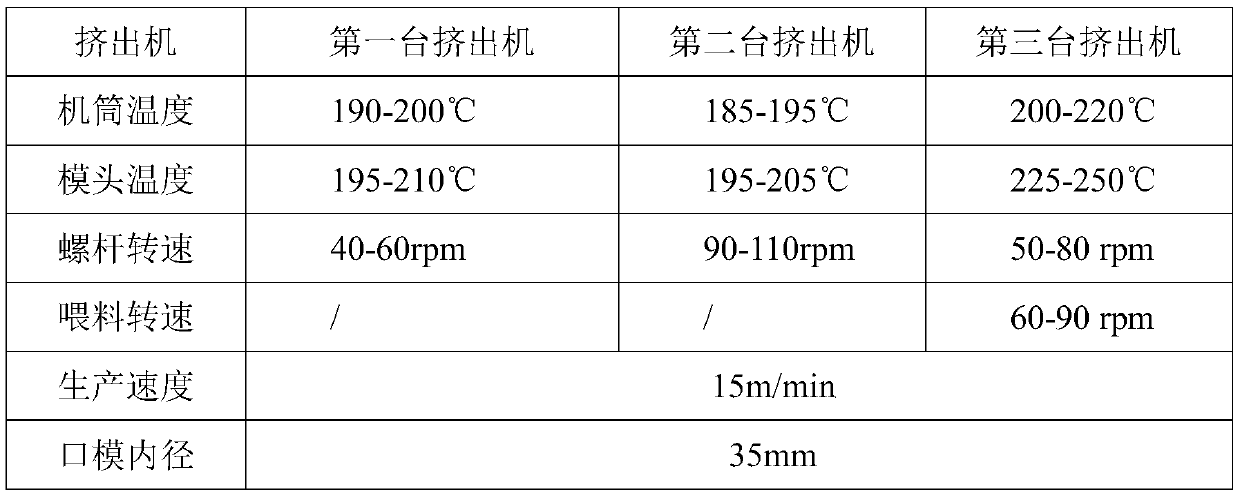

[0043] The method for preparing the anti-scaling plastic pipe with far-infrared radiation function, the specific steps are:

[0044] Add the far-infrared radiation composite material of the far-infrared radiation layer 1 into the first extruder;

[0045] Stir the heat-resistant polyethylene material of the polyolefin resin layer 2 evenly and add it to the second extruder;

[0046] Stir the anti-scaling composite material of the anti-scaling layer 3 evenly and add it to the third extruder;

[0047] Three extruders are used for three-layer co-extrusion, and after vacuum sizing, cooling and shaping, the anti-scaling plastic pipe with far-infrared radiation function is obtained.

[0048] The preparation method of the far infrared radiation composite material of the far infrared radiation layer 1 is as follows:

[0049] Weigh the dried graphene, graphite powder, bamboo charcoal powder, tourmaline powder, carbon black powder, far-infrared ceramic powder and carbon nanotubes according to the pr...

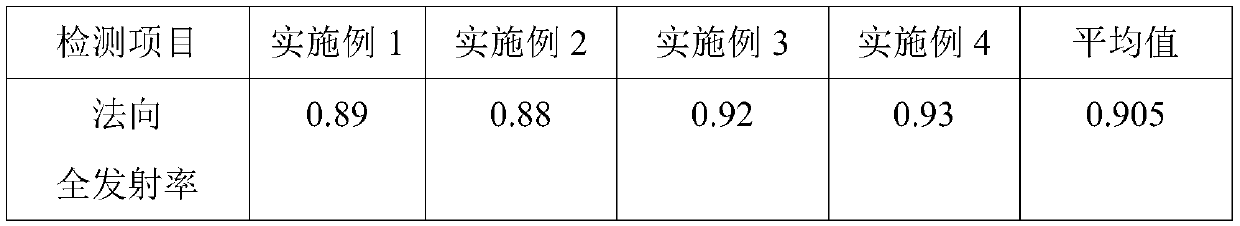

specific Embodiment 1

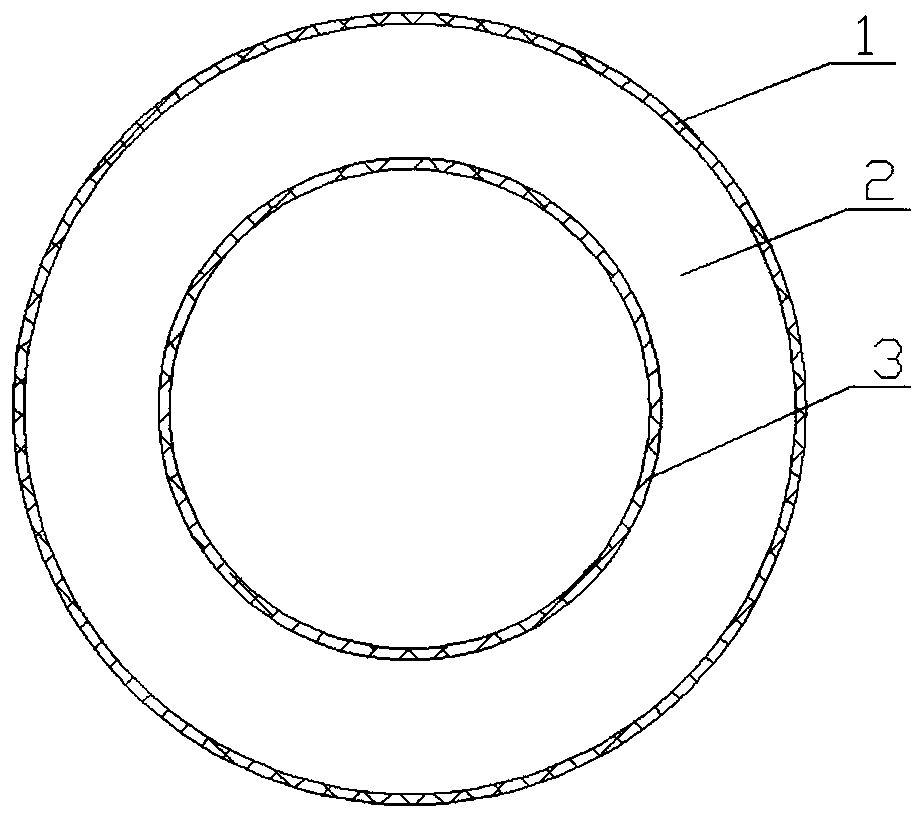

[0056] An anti-fouling plastic pipe with far-infrared radiation function, comprising a far-infrared radiation layer 1, a polyolefin resin layer 2, and an anti-fouling layer 3 arranged in sequence from the outside to the inside. The far-infrared radiation layer 1, polyolefin The thickness ratio of the resin layer 2 and the anti-scaling layer 3 is: 1:8:1;

[0057] The far-infrared radiation layer 1 is extruded from a far-infrared radiation composite material; the composition and mass parts of the far-infrared radiation composite material are: 100 parts of heat-resistant polyethylene and 3 parts of functional masterbatch;

[0058] The polyolefin resin layer 2 is extruded from a heat-resistant polyethylene material;

[0059] The anti-scaling layer 3 is extruded from an anti-scaling composite material; the composition and mass parts of the anti-scaling composite material are: 100 parts of ultra-high molecular weight polyethylene, fluorine-containing silicone modified PE 4 copies of maste...

specific Embodiment 2

[0069] An anti-fouling plastic pipe with far-infrared radiation function, comprising a far-infrared radiation layer 1, a polyolefin resin layer 2, and an anti-fouling layer 3 arranged in sequence from the outside to the inside. The far-infrared radiation layer 1, polyolefin The thickness ratio of the resin layer 2 and the anti-scaling layer 3 is: 1:8:1;

[0070] The far-infrared radiation layer 1 is extruded from a far-infrared radiation composite material; the composition and mass parts of the far-infrared radiation composite material are: 100 parts of heat-resistant polyethylene and 4 parts of functional masterbatch;

[0071] The polyolefin resin layer 2 is extruded from a heat-resistant polyethylene material;

[0072] The anti-scaling layer 3 is extruded from an anti-scaling composite material; the composition and mass parts of the anti-scaling composite material are: 100 parts of ultra-high molecular weight polyethylene, fluorine-containing silicone modified PE 5 copies of maste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com