SO2 depolarization electrolytic tank

An electrolytic cell and depolarization technology, applied in the field of electrochemistry, can solve the problems of easy cracking, high processing cost, and high cost, and achieve the effects of high chemical stability, improved efficiency, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

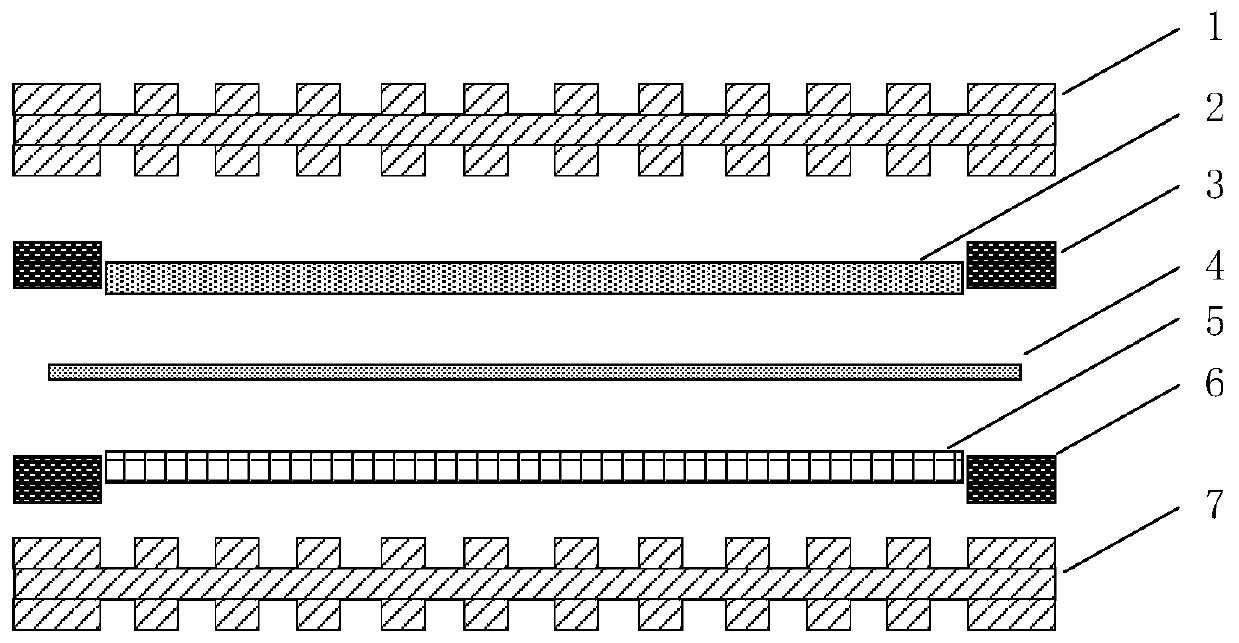

[0035] Using the scheme of the present invention, the SO 2 In depolarized electrolytic cells, the membrane electrode assembly consists of an anode catalyst layer, a proton selective permeable membrane and a cathode catalyst layer. Among them, the proton selective permeable membrane is Nafion 115 (DuPont Company) proton exchange membrane, which is sprayed with Pt / C catalyst layer on both sides, and the effective membrane area of each single cell is 50cm 2 , the amount of Pt used is 0.6mg / cm 2 , the amount of Pt used on the cathode side and the anode side is the same, each 0.3mg / cm 2 . On both sides of the membrane electrode assembly, a cathode-side support body 2 , an upper pole plate 1 , an anode-side support body 5 , and a lower pole plate 7 are distributed sequentially. The cathode side support is 0.3 mm thick carbon paper, and the anode side support is 0.5 mm graphite felt (85% porosity, 99.5% carbon content).

[0036] Both the upper and lower plates are 1mm thick tit...

Embodiment 2

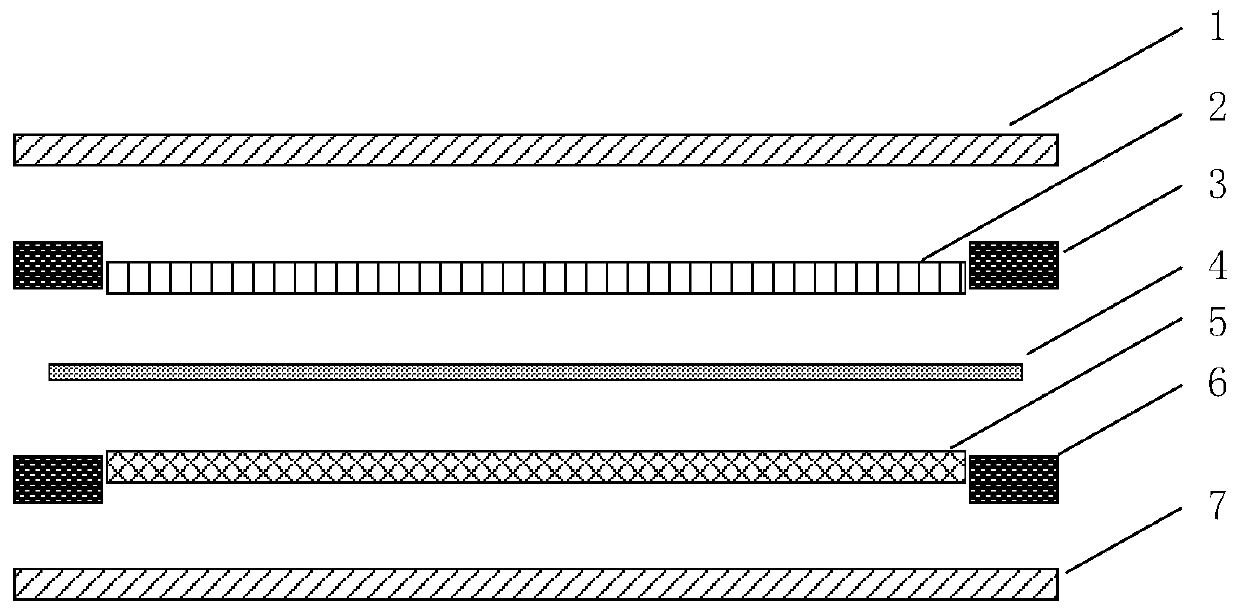

[0040] Using the solution of the present invention, the SO 2 In depolarized electrolytic cells, the membrane electrode assembly consists of an anode catalyst layer, a proton selective permeable membrane and a cathode catalyst layer. Among them, the proton selective permeation membrane is selected as Nafion 117 (DuPont Company) proton exchange membrane, and the Pt / C catalyst layer is sprayed on both sides, and the effective membrane area of each single cell is 100cm 2 , the amount of Pt used is 0.5mg / cm 2 , the amount of Pt used on the cathode side and the anode side is the same, each 0.25mg / cm 2 . On both sides of the membrane electrode assembly, a cathode side support body, an upper pole plate, an anode side support body, and a lower pole plate are sequentially distributed. Both the cathode-side support and the anode-side support are 4 cm thick graphite felt (porosity 92%, carbon content 99.9%).

[0041] Both the upper plate and the lower plate are hard graphite plates ...

Embodiment 3

[0046] Using the solution of the present invention, the SO 2 In depolarized electrolytic cells, the membrane electrode assembly consists of an anode catalyst layer, a proton selective permeable membrane and a cathode catalyst layer. Among them, the proton selective permeation membrane is selected as Nafion 117 (DuPont Company) proton exchange membrane, and the Pt / C catalyst layer is sprayed on both sides, and the effective membrane area of each single cell is 100cm 2 , the amount of Pt used is 0.5mg / cm 2 , the amount of Pt used on the cathode side and the anode side is the same. On both sides of the membrane electrode assembly, a cathode side support body, an upper pole plate, an anode side support body, and a lower pole plate are sequentially distributed. The anode side support is 2.5mm graphite felt (porosity 92%, carbon content 99.9%), the cathode side support is 3.5mm graphite felt (porosity 92%, carbon content 99.9%) and 0.3mm thick carbon paper , in which the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com