Ion-electron hybrid conductive metal sodium negative electrode and preparation method thereof

A metal sodium and negative electrode technology, which is applied in the field of sodium ion battery electrode materials and its preparation, can solve the problems of electrolyte exposure, electrode interface can not be kept stable, aggravated active sodium and electrolyte consumption, etc., to achieve high overall electrode capacity, inhibit Volume change and inhomogeneous deposition/stripping behavior, effect of electrode microstructure densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

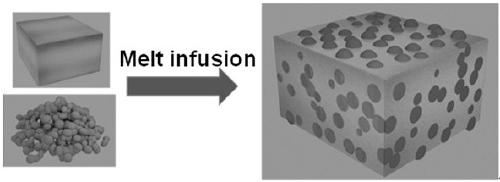

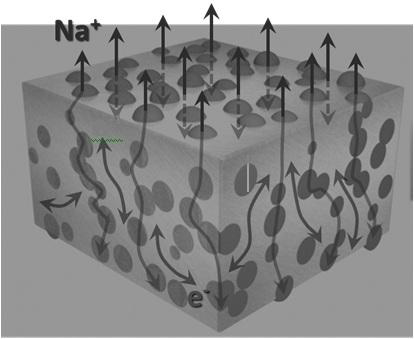

[0042] It mainly includes three processes of synthesizing solid electrolyte, pretreatment of solid electrolyte, and melting and mixing with metal sodium to prepare electrodes.

[0043] (1) Synthesis of solid electrolyte Na 3.4 Zr 2 Si 2.4 P 0.6 o 12 : NaNO 3 and ZrO(NO 3 ) 2 dissolved in distilled water, and then Si(OCH 2 CH 3 ) 4 and NH 4 h 2 PO 4 Added to the solution, the amount of the reagent is strictly in accordance with Na 3.4 Zr 2 Si 2.4 P 0.6 o 12 stoichiometric ratio. After drying at 85 °C, the obtained powder was calcined at 1100 °C for 3 h to obtain NZSP powder.

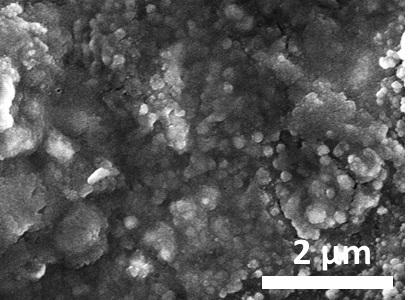

[0044] (2) Solid electrolyte pretreatment: SnCl 2 Dissolve in N,N-dimethylformamide (DMF) to obtain 0.5 molL -1 SnCl 2 solution. Then add an appropriate amount of NZSP powder, the SnCl in the solution 2 The quality control is 15% of the NZSP quality. After stirring for 2 h, the solution was dried overnight in an oven at 80 °C. Subsequently, the powder was ground in an agate grindi...

Embodiment 2

[0047] It mainly includes three processes of synthesizing solid electrolyte, pretreatment of solid electrolyte, and melting and mixing with metal sodium to prepare electrodes.

[0048] (1) Synthesis of solid electrolyte Na 3.2 Zr 2 Si 2.2 P 0.8 o 12 : NaNO 3 and ZrO(NO 3 ) 2 dissolved in distilled water, and then Si(OCH 2 CH 3 ) 4 and NH 4 h 2 PO 4 Added to the solution, the amount of reagent according to Na 3.2 Zr 2 Si 2.2 P 0.8 o 12 The stoichiometric ratio was weighed. After drying at 85 °C, the obtained powder was calcined at 1000 °C for 3 h to obtain NZSP powder.

[0049] (2) Solid electrolyte pretreatment: SnCl 2 Dissolve in N,N-dimethylformamide (DMF) to obtain 0.4 molL -1 SnCl 2 solution. Then add an appropriate amount of NZSP powder, the SnCl in the solution 2 The quality control is 10% of the NZSP quality. After stirring for 2 h, the solution was dried overnight in an oven at 80 °C. Subsequently, the powder was ground in an agate grinding dis...

Embodiment 3

[0052] It mainly includes three processes of synthesizing solid electrolyte, pretreatment of solid electrolyte, and melting and mixing with metal sodium to prepare electrodes.

[0053] (1) Synthesis of solid electrolyte Na 3 Zr 2 Si 2 PO12 : NaNO 3 and ZrO(NO 3 ) 2 dissolved in distilled water, and then Si(OCH 2 CH 3 ) 4 and NH 4 h 2 PO 4 Added to the solution, the amount of reagent according to Na 3 Zr 2 Si 2 PO 12 The stoichiometric ratio was weighed. After drying at 85 °C, the obtained powder was calcined at 1100 °C for 4 h to obtain NZSP powder.

[0054] (2) Solid electrolyte pretreatment: SnCl 2 Dissolve in N,N-dimethylformamide (DMF) to obtain 0.6 molL -1 SnCl 2 solution. Then add an appropriate amount of NZSP powder, the SnCl in the solution 2 The quality control is 20% of the NZSP quality. After stirring for 2 h, the solution was dried overnight in an oven at 80 °C. Subsequently, the powder was ground in an agate grinding dish for 5 min, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com