Anti-efflorescence high-strength inorganic artificial stone material and preparation process thereof for decorative plate

An inorganic cementitious material and high-strength technology, applied in the direction of manufacturing tools, clay preparation equipment, ceramic molding machines, etc., can solve the problems of not enough to effectively block the pan-alkaline channel, limited improvement of the pan-alkaline problem, etc., and achieve excellent anti-pan-alkaline performance, avoid pan-alkali phenomenon, and simplify the effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

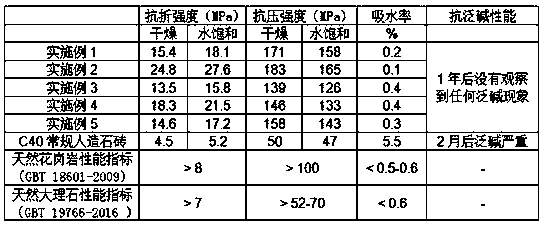

Examples

Embodiment 1

[0029] An anti-efflorescence high-strength inorganic artificial stone material is composed of the following components in parts by weight: 1 part of inorganic gelling material, 1.7 parts of sand aggregate, 0.005 part of polycarboxylic acid superplasticizer, and 0.16 part of water.

[0030] The inorganic gelling material is made of ordinary portland cement with a strength grade of 52.5, fly ash, and precipitated silica with a particle size below 10 nanometers in a weight ratio of 1:0.29:0.09. The sand and gravel aggregate is made of natural granite aggregate with a particle size of less than 10 mm and ordinary building sand and gravel aggregate with a particle size of less than 10 mm in a weight ratio of 92%:8%.

[0031] Preparation of anti-efflorescence high-strength inorganic artificial stone decorative board: Weigh the raw materials in proportion, pour all the weighed dry materials into the forced concrete mixer, dry mix for 30 seconds, add water and stir for 3 minutes, and m...

Embodiment 2

[0033] An anti-efflorescence high-strength inorganic artificial stone material, which is composed of the following components by weight: 1 part of inorganic cementitious material, 2.2 parts of sand aggregate, 0.019 part of melamine high-efficiency water reducer, and 0.05 part of ultra-high molecular weight polyethylene fiber parts (length 20-40mm, diameter 0.02-0.03mm), water 0.21 parts.

[0034] The inorganic gelling material is made of ordinary Portland cement with a strength grade of 52.5, blast furnace slag powder, silica fume, and precipitated silica with a particle size below 10 nanometers in a weight ratio of 1: 0.14: 0.04: 0.05. The sandstone aggregate is composed of natural granite aggregate with a particle size of less than 10mm and ordinary building sandstone aggregate with a particle size of less than 10mm in a weight ratio of 57%:43%.

[0035] Example 2 The preparation steps of the anti-pantherine high-strength inorganic artificial stone decorative plate are the s...

Embodiment 3

[0037]An anti-efflorescence high-strength inorganic artificial stone material, which is composed of the following components in parts by weight: 1 part of inorganic cementitious material, 2.8 parts of sand and gravel aggregate, 0.016 part of polycarboxylic acid superplasticizer, ultra-high molecular weight polyethylene Fiber 0.02 parts (length 20-40mm, diameter 0.02-0.03mm), water 0.23 parts.

[0038] The inorganic cementitious material is made of ordinary Portland cement with a strength grade of 52.5, fly ash, blast furnace slag powder, and precipitated silica with a particle size below 10 nanometers in a weight ratio of 1:0.08:0.14:0.04. . The natural marble aggregate with a particle size of less than 10 mm and the ordinary building sand aggregate with a particle size of less than 10 mm are prepared by mixing the sand and gravel aggregate in a weight ratio of 74%:26%.

[0039] Example 3 The preparation steps of the efflorescence-resistant high-strength inorganic artificial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com