Electromagnetic shielding epoxy composite material with isolation structure and preparation method

A technology of electromagnetic shielding and composite materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., to achieve the effect of improving mechanical properties, excellent performance, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

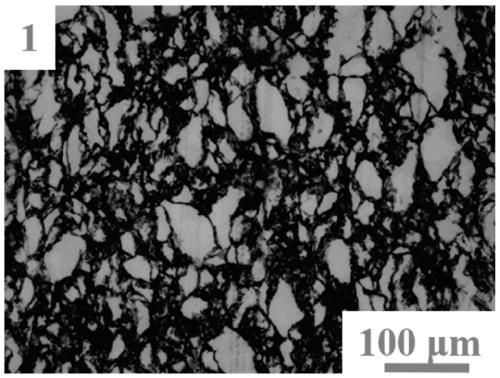

Embodiment 1

[0032] The preparation operation steps of an electromagnetic shielding epoxy composite material with an isolation structure are as follows:

[0033] (1) Stir 5.9g of polymerized fatty acid (59wt%) and 0.5g of catalyst (5wt%) at a temperature of 70°C and a relative vacuum of -80 to -100KPa; the acid value of the polymerized fatty acid is 191mg KOH / g, which contains about 82 wt% trimer acid and 18 wt% dimer acid; the catalyst is zinc acetate. When the temperature was raised to 180°C at a heating rate of 3°C / min, and kept at a temperature of 180°C and a relative vacuum of -80 to -100KPa for 2 hours, a substance A was obtained, which was a light brown viscous liquid.

[0034] (2) Lower the temperature of A to 60°C, add 3.4g of epoxy resin (34wt%), and keep stirring for 0.5h, and react for 6h at 130°C to obtain B, which is glass-like Dynamically cross-linked epoxy resin (epoxy vitrimer).

[0035](3) Crush material B, and sieve epoxy vitrimer particles with a particle size of 50-...

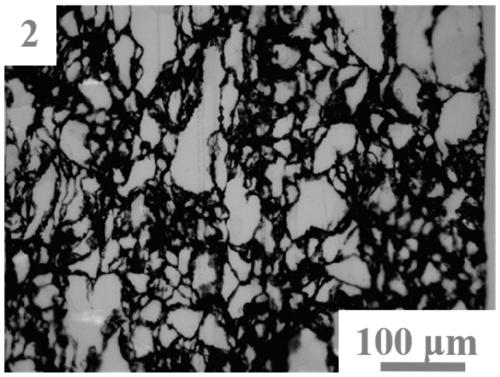

Embodiment 2

[0039] The preparation operation steps of an electromagnetic shielding epoxy composite material with an isolation structure are as follows:

[0040] (1) Stir 5.8g of polymerized fatty acid (58wt%) and 0.5g of catalyst (5wt%) at a temperature of 70°C and a relative vacuum of -80 to -100KPa; the acid value of the polymerized fatty acid is 191mg KOH / g, which contains about 82 wt% trimer acid and 18 wt% dimer acid; the catalyst is zinc acetate. When the temperature was raised to 180°C at a heating rate of 3°C / min, and kept at a temperature of 180°C and a relative vacuum of -80 to -100KPa for 2 hours, a substance A was obtained, which was a light brown viscous liquid.

[0041] (2) Lower the temperature of A to 60°C, add 3.3g of epoxy resin (33wt%), and keep stirring for 0.5h, and react at 130°C for 6h to obtain B, which is glass-like Dynamically cross-linked epoxy resin (epoxy vitrimer).

[0042] (3) Crush material B and sieve epoxy vitrimer particles with a particle size of 50-...

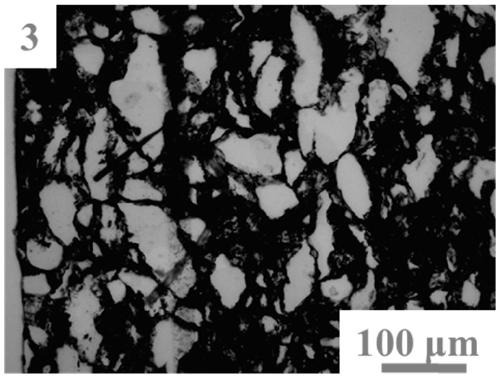

Embodiment 3

[0046] The preparation operation steps of an electromagnetic shielding epoxy composite material with an isolation structure are as follows:

[0047] (1) Stir 5.6g of polymerized fatty acid (56wt%) and 0.5g of catalyst (5wt%) at a temperature of 70°C and a relative vacuum of -80 to -100KPa; the acid value of the polymerized fatty acid is 191mg KOH / g, which contains about 82 wt% trimer acid and 18 wt% dimer acid; the catalyst is zinc acetate. When the temperature was raised to 180°C at a heating rate of 3°C / min, and kept at a temperature of 180°C and a relative vacuum of -80 to -100KPa for 2 hours, a substance A was obtained, which was a light brown viscous liquid.

[0048] (2) Lower the temperature of A to 60°C, add 3.1g of epoxy resin (31wt%), and keep stirring for 0.5h, and react for 6h at 130°C to obtain B, which is glass-like Dynamically cross-linked epoxy resin (epoxy vitrimer).

[0049] (3) Crush material B and sieve epoxy vitrimer particles with a particle size of 50-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com