Black polyimide film comprising fluororesin, and preparation method therefor

The technology of polyimide film and polyimide resin is applied in the field of black polyimide film and its preparation, which can solve the problems of reduced function of cover film, black color tone, reduced concealment, reduced thickness, etc. The effect of excellent gloss, excellent alkali resistance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

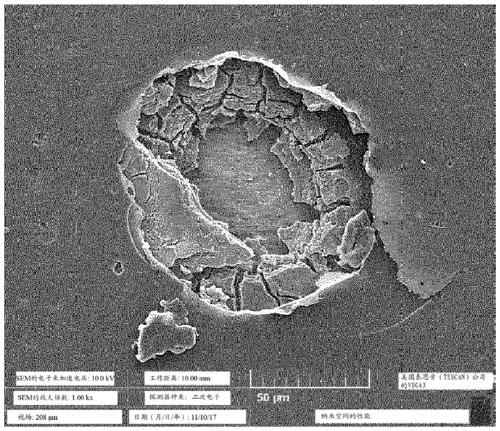

Image

Examples

preparation example 1

[0092] Preparation Example 1: Polymerization of Polyamic Acid

[0093] As a polyamic acid solution polymerization process, 407.5 g of dimethylformamide (DMF) was added as a solvent in a 500 mL reactor under a nitrogen atmosphere.

[0094] After setting the temperature to 25°C, add 35.90 g of 4,4'-diphenylamine oxide as a diamine monomer, and stir for about 30 minutes. After confirming that the monomer is dissolved, add 35.90 g of pyromellitic dianhydride as a diamine monomer. Dianhydride monomer, and added after adjusting the final addition amount so that the final viscosity is 2,500,000 to 2,800,000 cps.

[0095] After the addition was complete, the temperature was maintained while stirring for 1 hour to polymerize the amic acid solution to a final viscosity of 2800 million centipoise.

preparation example 2

[0096] Preparation Example 2: Preparation of Composition Containing Fluorine Resin and Carbon Black

[0097] After mixing 70 g of DMF as the first organic solvent and 30 g of PFA resin as the fluororesin, a first composition having a solid content of 30% was prepared.

[0098] After mixing 89 g of DMF as the second organic solvent, 10 g of carbon black, and 1 g of dispersant BYK-430, a second composition containing carbon black with an average particle diameter of 0.5 μm was prepared using a grinder.

[0099] After mixing 100 g of the first composition with 100 g of the second composition, a third composition was prepared.

preparation example 3

[0100] Preparation Example 3: Preparation of Polyimide Film

[0101] The 30g polyamic acid solution prepared in the preparation example 1 is mixed with the third composition of 5g prepared in the preparation example 2, and 4.76g of isoquinoline (IQ), 26.36g of acetic anhydride (AA), And after the DMF of 18.87g is used as catalyst, mix evenly, use scraper knife to cast on stainless steel (SUS) plate (100SA, Sweden Sandvik (Sandvik) company produces) to 70 μm, and then in the temperature range of 100 ℃ to 200 ℃ to dry.

[0102] Then, the film was peeled from the SUS sheet and fixed on a pin-type frame, and then transferred to a high-temperature tenter.

[0103] After the film was heated from 200°C to 600°C on a high-temperature tenter, cooled at 25°C, and then separated from the pin frame, a polyimide film with a thickness of 7.5 μm was prepared. The total weight of the film, the film comprises 90% by weight of polyimide resin, 5% by weight of carbon black and 5% by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com