A wicker wear-resistant cutting knife for wicker

A cutting knife and willow weaving technology, which is applied in the field of willow weaving wear-resistant cutting knives for wicker making, can solve the problems of passivation, easy slipping and wear of the knife head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

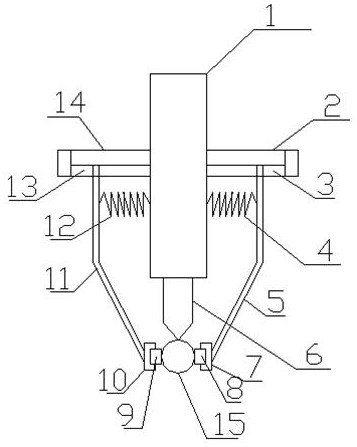

Image

Examples

Embodiment 1

[0041] Rare earth composite nanoparticles reinforced alumina ceramic material cutter head is obtained by mixing rare earth composite nanoparticles, alumina powder and silicon carbide powder, adding them to the mold for pressing, and finally sintering. The mass ratio of alumina powder and silicon carbide powder is 60 :30, the mass fraction of rare earth composite nanoparticles in the cutter head is 0.6%. The preparation method of rare earth composite nanoparticles is as follows: add cerium nitrate to nano zeolite powder-nano copper mixed particles, stir evenly, then add to the grinder, and then add tartaric acid, maleic acid, acrylamide to the grinder respectively , N, N'-methylenebisacrylamide, heated to 80 ° C, ground for 2 hours, and then dried to obtain a dry mixture, and then added the obtained dry mixture to a calciner for calcination treatment to obtain a rare earth composite nano particles. The mass ratio of the nano zeolite powder to the nano copper mixed particle in ...

Embodiment 2

[0043] The cutter head of rare earth composite nanoparticle reinforced alumina ceramic material is obtained by mixing rare earth composite nanoparticle, alumina powder and silicon carbide powder, adding them to the mold for pressing, and finally sintering. The mass ratio of alumina powder and silicon carbide powder is 70 :35, the mass fraction of rare earth composite nanoparticles in the cutter head is 1.2%. The preparation method of rare earth composite nanoparticles is as follows: add cerium nitrate to nano zeolite powder-nano copper mixed particles, stir evenly, then add to the grinder, and then add tartaric acid, maleic acid, acrylamide to the grinder respectively , N, N'-methylene bisacrylamide, heated to 90 ° C, ground for 3 hours, and then dried to obtain a dry mixture, and then added to the calciner for calcination to obtain a rare earth composite nano particles. The mass ratio of the nano zeolite powder to the nano copper mixed particle in the nano zeolite powder-nan...

Embodiment 3

[0045] Rare earth composite nanoparticles reinforced alumina ceramic material cutter head is obtained by mixing rare earth composite nanoparticles, alumina powder and silicon carbide powder, adding them to the mold for pressing, and finally sintering. The mass ratio of alumina powder and silicon carbide powder is 66 :33, the mass fraction of rare earth composite nanoparticles in the cutter head is 0.8%. The preparation method of rare earth composite nanoparticles is as follows: add cerium nitrate to nano zeolite powder-nano copper mixed particles, stir evenly, then add to the grinder, and then add tartaric acid, maleic acid, acrylamide to the grinder respectively , N, N'-methylenebisacrylamide, heated to 82 ° C, ground for 2.5 hours, and then dried to obtain a dry mixture, and then added to the calciner for calcination to obtain a rare earth composite nano particles. The mass ratio of the nano zeolite powder to the nano copper mixed particle in the nano zeolite powder-nano co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com