Combined treatment agent for wastewater produced during oily paint spraying and using method thereof

A treatment agent and waste water technology, which is applied in the field of spray paint waste water, can solve the problems such as difficulty in floating paint slag, limited adsorption capacity of activated carbon filter, high operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

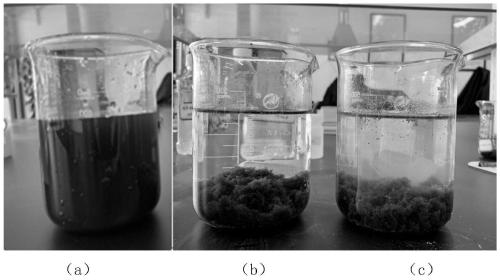

Image

Examples

Embodiment 1

[0053] The components of the paint mist breaker are based on the amount (n) ratio of melamine: formaldehyde: hydrochloric acid: urea: water = 1:2:1.2:0.5:3.5, and the reaction temperature is between 60 and 70°C. Made in 4h;

[0054] The coagulation aid is prepared as a 10wt% medicament solution;

[0055] The coagulant is prepared into a medicament solution of 2wt‰;

[0056] Take 400ml of water sample, add 5ml of viscosifier, stir slowly clockwise at a constant speed, fine suspended particles begin to appear in the water sample, then add 3.5ml of coagulant aid, stir slowly at a uniform speed clockwise, the fine suspended particles in the solution begin to flocculate into small groups, The water quality starts to become clear, finally add 3.5ml coagulant, and stir slowly clockwise at a constant speed. At this time, the fine suspended particles in the solution begin to coalesce into large flocs, and sink slowly, and the stratification is obvious. At this time, the water quality ...

Embodiment 2

[0061] The components of the paint mist breaker are based on the amount (n) ratio of melamine: formaldehyde: hydrochloric acid: urea: water = 1: 1.5: 1: 1: 3.4, and the reaction temperature is between 60 and 70 ° C. Made in 4h;

[0062] The coagulation aid is prepared as a 10wt% medicament solution;

[0063] The coagulant is prepared into a medicament solution of 2wt‰;

[0064] Take 400ml of water sample, add 5ml viscosifier, stir slowly clockwise, add 3.5ml coagulant, stir slowly clockwise, add 3.5ml coagulant, stir slowly clockwise.

[0065] Table 4 embodiment 2 water quality detection result

[0066] pH COD (mg / L) SS(mg / L) raw water 7.5 2500 200 Example 2 8.0 102.5 43 Removal rate / 95.9% 78.5%

Embodiment 3

[0068] The components of the paint mist breaker are based on the amount (n) ratio of melamine: formaldehyde: hydrochloric acid: urea: water = 1.1:1:1.1:0.8:3, and the reaction temperature is between 60 and 70°C. Made in 4h;

[0069] The coagulation aid is prepared as a 10wt% medicament solution;

[0070] The coagulant is prepared into a medicament solution of 2wt‰;

[0071] Take 400ml of water sample, add 5ml viscosifier, stir slowly clockwise, add 3.5ml coagulant, stir slowly clockwise, add 3.5ml coagulant, stir slowly clockwise.

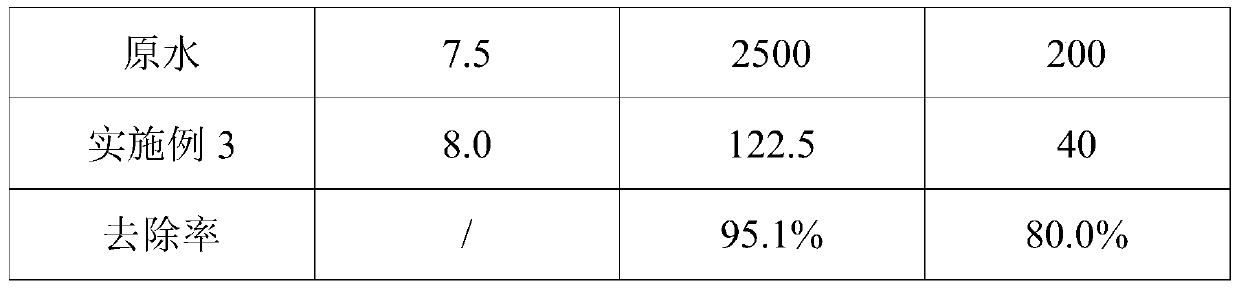

[0072] Table 5 embodiment 3 water quality detection result

[0073]

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com