Chimeric protein as well as preparation method and application thereof

A chimeric protein, protein technology, applied in chemical instruments and methods, single-component protein rayon, hybrid peptides, etc., can solve the problem of less fiber, chemical environment, rheological properties and physical pressure of natural spider silk spinning system Insufficient understanding, inability to use practical purposes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

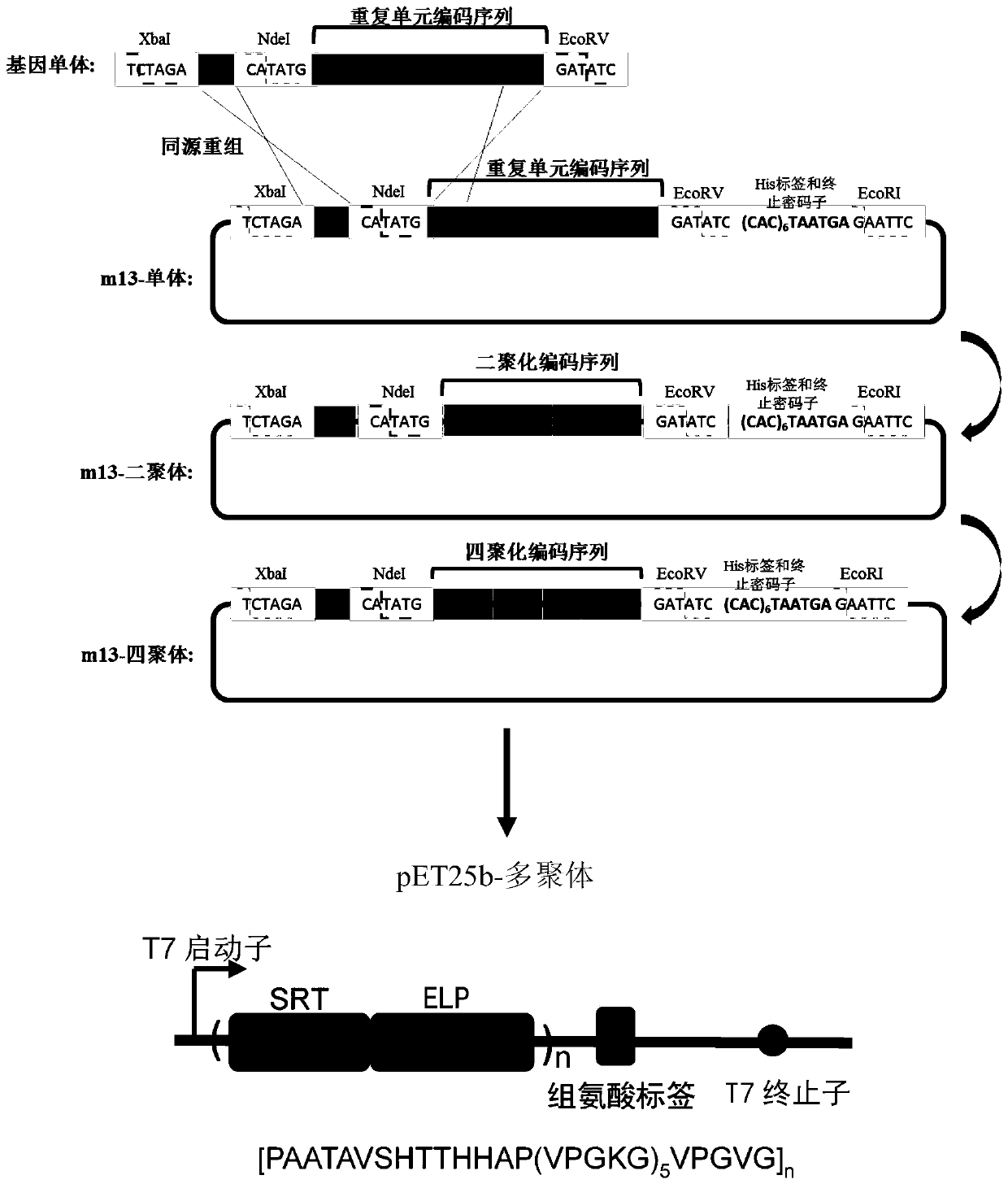

[0035] Embodiment 1: expression vector construction

[0036] Construction of the coding sequence of the SRT-ELP protein unit (SRT protein coding sequence SEQ ID NO:3+ELP protein coding sequence SEQ ID NO:4), and XbaI restriction site (TCTAGA), homology arm 1 (CTGCAGGAATTCGTTATC, SEQ IDNO :5), NdeI restriction site (CATATG), homology arm 2 (SEQ ID NO: 3 sequence 1-21bp), EcoRV restriction site (GATATC), histidine tag sequence ((CAC) 6 ), the DNA coding sequence corresponding to the stop codon (TAATGA) and the EcoRI restriction site (GAATTC), all elements are connected to obtain gene element 1, XbaI+homology arm 1+NdeI+SRT-ELP protein unit coding sequence+homology arm 2+EcoRV+(CAC) 6 +TAATGA+EcoRI; connect gene element 1 and m13 plasmid by XbaI and EcoRI double digestion to obtain chimeric protein monomer vector (m13-monomer);

[0037] The gene element 2 was obtained from the m13-monomer by XbaI and EcoRV double digestion, and the gene element 2 and the m13-monomer digested by...

Embodiment 2

[0040] Example 2: Protein expression and purification

[0041] The expression vector "pET25b-polymer" was transformed into Escherichia coli competent cells E.coli BLR(DE3). Pick positive clones and culture them in 10ml LB medium (100μg / ml ampicillin) for 8-12 hours (37°C, 220rpm). The volume of the shaker flask is 100ml. 500ml LB medium (200μg / ml ampicillin) in a large shaker flask (volume 500ml) and cultured for 1.5-3 hours (37°C, 220rpm), when the OD600 of the bacterial solution reached 0.5-0.7, add the inducer IPTG (isopropylβ-D -1-thiogalactopyranoside, isopropylthiogalactopyranoside) to a final concentration of 1mM, to induce a large amount of protein expression, and after 4 hours of fermentation (37°C, 220rpm), the bacterial liquid was centrifuged (7000g, 20min, 4°C), and the Bacteria were stored at -80°C.

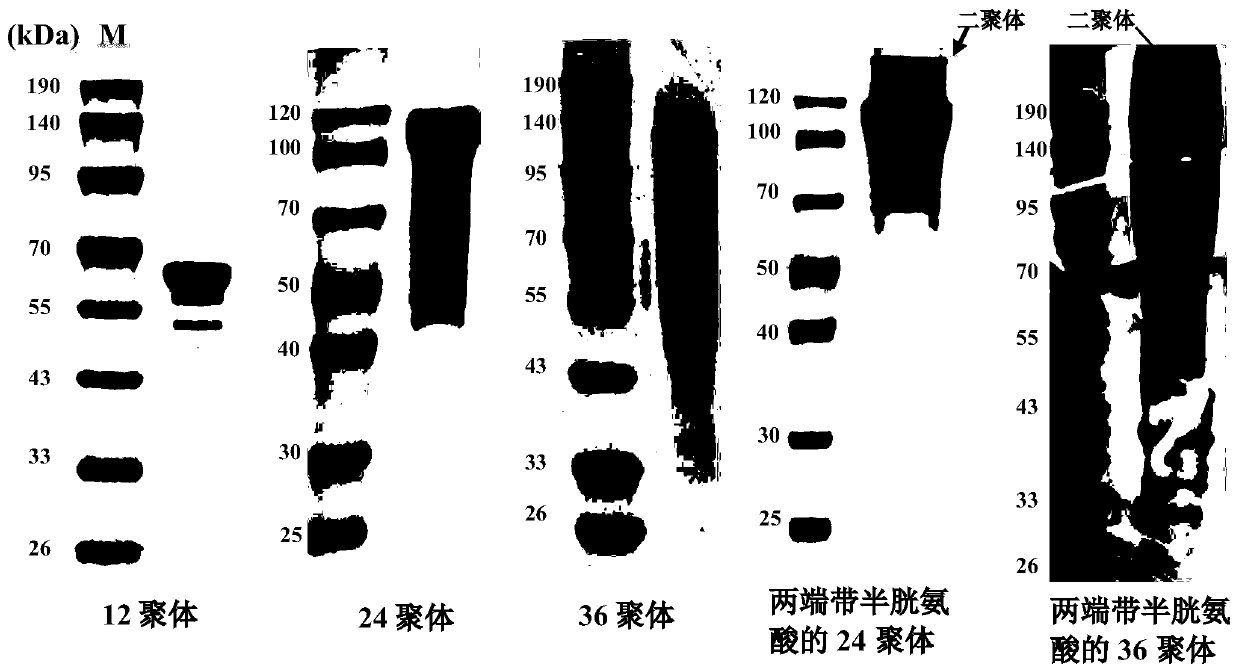

[0042] The cells were ultrasonically disrupted and centrifuged (11000g, 30min, 4°C) to take the supernatant, which was then passed through a nickel column, a desal...

Embodiment 3

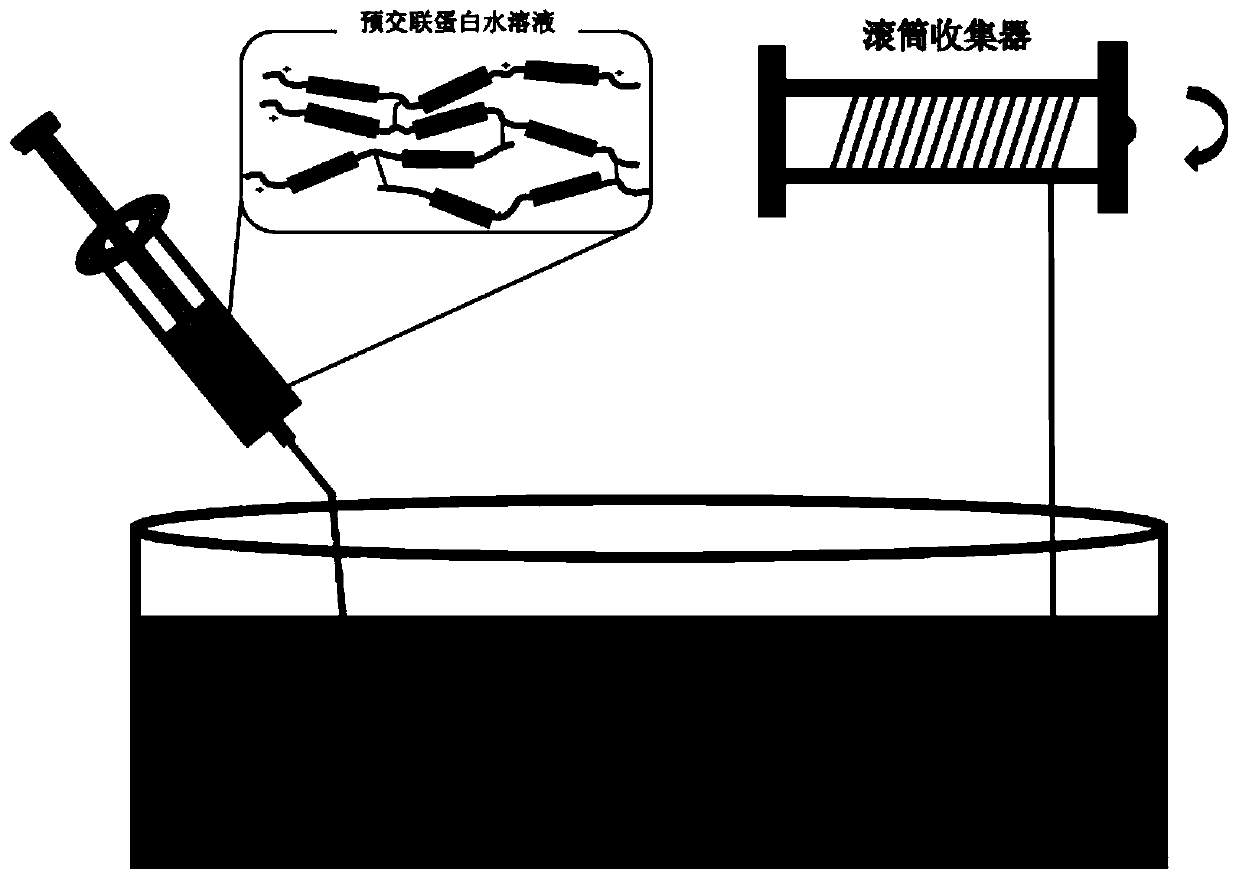

[0043] Embodiment 3: the preparation of biological protein fiber

[0044] Add an aqueous glutaraldehyde solution with an initial mass concentration of 0.1% to an aqueous protein solution (200 mg / ml) of the SRT-ELP polymer, dilute the final concentration of glutaraldehyde to a mass concentration of 0.01%, and crosslink for 10 minutes.

[0045] Squeeze the pre-crosslinked protein aqueous solution into a 0.5% glutaraldehyde aqueous solution (coagulation bath) with a syringe, and use a syringe pump to adjust the advancing speed to 10 μl / min, and use a rotary drum collector at a linear speed of 0.6m. / min speed to collect fibers, the schematic will be figure 2 .

[0046] Dry the collected fibers, soak them in ultrapure water for three seconds until the fibers curl up and become soft, and then take out the fibers and immediately stretch them to 100% of their original length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com