Method for promoting alcohol production of biomass material

A biomass material and enzymatic hydrolysis technology, applied in the field of promoting biomass material alcohol production, can solve the problems that fermentation inhibitors cannot be effectively reduced, the enzymatic hydrolysis efficiency is not significantly improved, and the cost is high, and the sugar alcohol conversion rate can be improved, and the cost is low. , Strong anti-stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

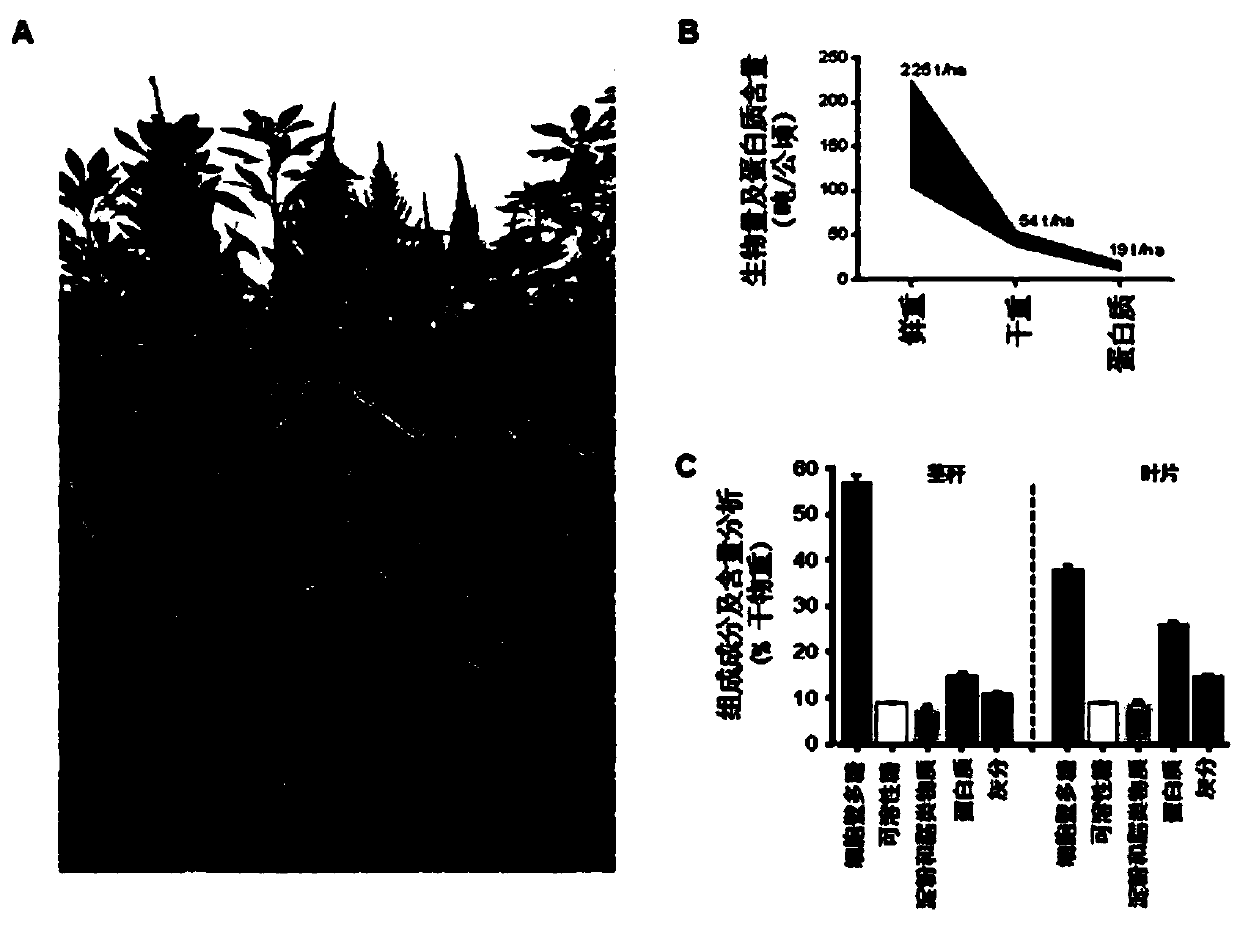

[0050] (1) Extraction of grain amaranth protein

[0051] Take the fresh leaf tissue of amaranth in the growth period, grind it with liquid nitrogen, add 0.2M NaAC (pH=4.8) as a buffer, grind until homogenized, centrifuge at 40000rpm at 4°C for 10min, measure the protein concentration in the supernatant by Brandford method, and measure the protein concentration in the supernatant. When the protein concentration in the medium is more than 10ug / ml, store it at -20°C until use.

[0052] (2) Pretreatment of biomass materials

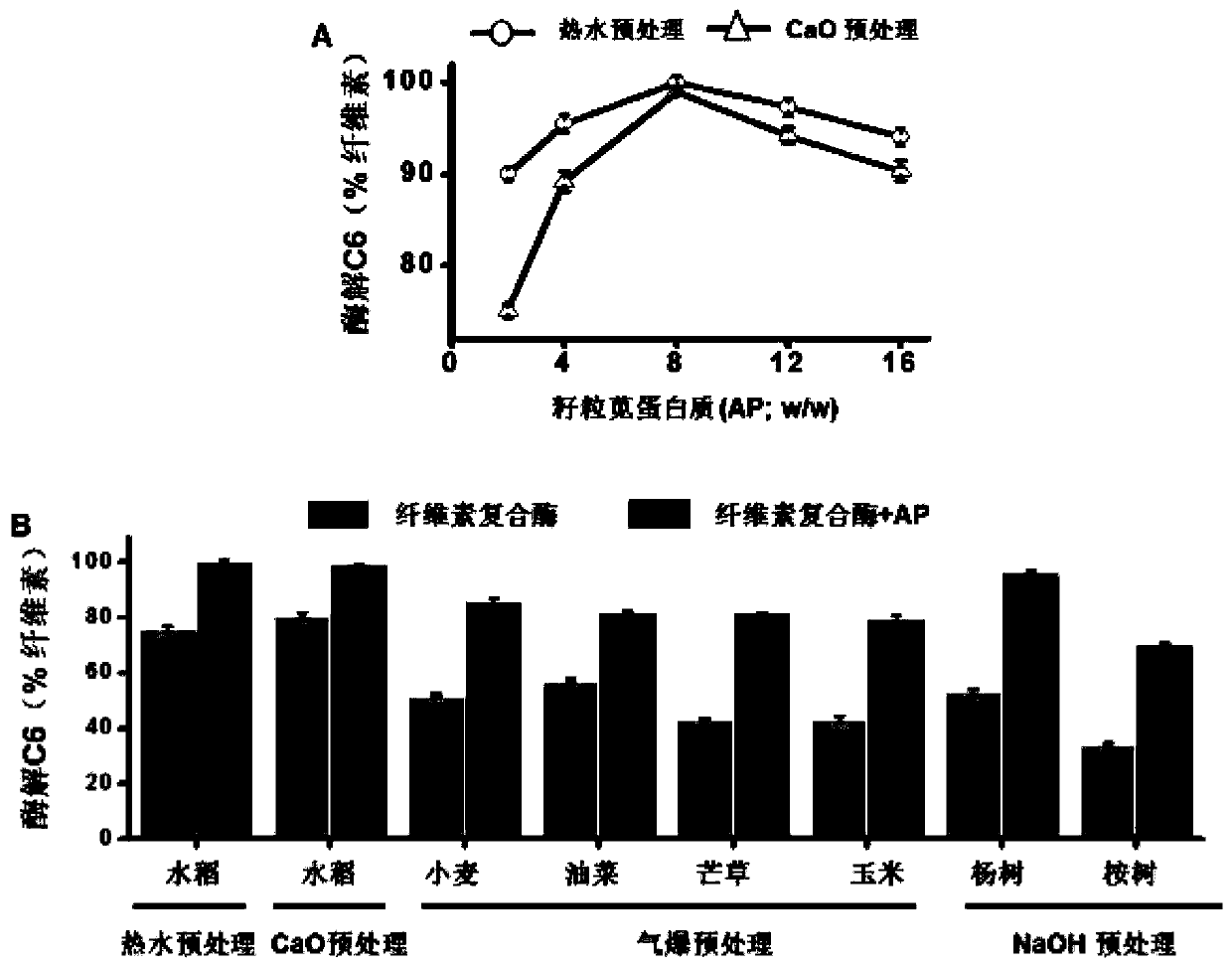

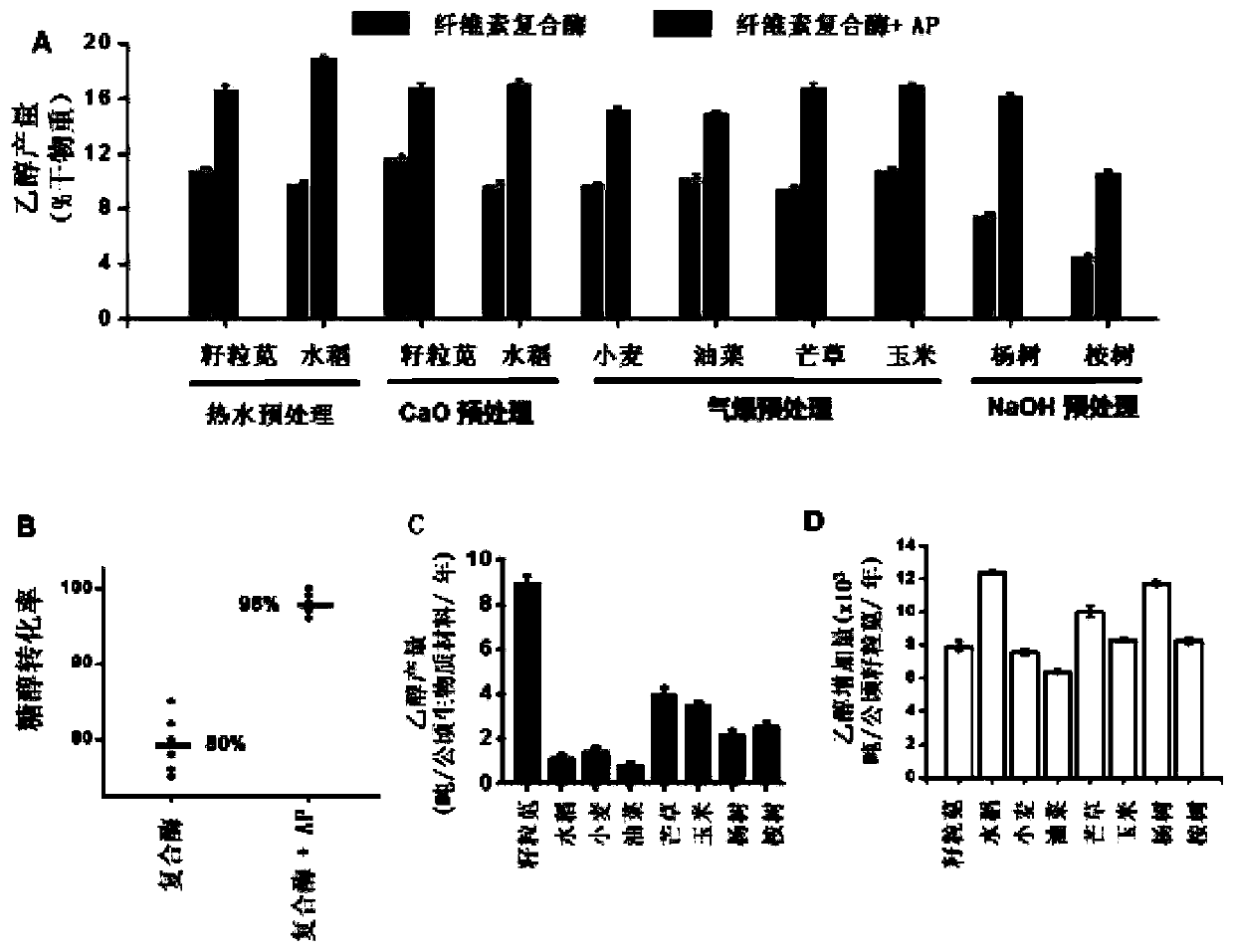

[0053] Gas explosion pretreatment with grain amaranth as raw material of biomass material: ① cut the dried material into 7cm segments, spray distilled water to make the material humidity reach 50% (that is, the wet weight of the material is equal to twice the dry weight); Put the shortened and sprayed materials into a gas explosion reactor with a capacity of 5L, and treat them at 225°C and 2.5MPa for 8 minutes; ℃ drying to constant weight, that is, the biom...

Embodiment 2

[0059] Same as Example 1, the only difference is that the pretreatment process of the biomass material is 10% CaO treatment, and the specific process is: ① after the material is dried, it is pulverized by a powder sample machine and passed through a 40-mesh sieve; ② Weigh 0.300g of biomass powder in Add CaO powder (CaO / biomass powder = 10%, w / w) and water to a 15mL centrifuge tube, centrifuge for 2 hours, and repeat each sample three times; , neutralize at 150r / min for 2h, centrifuge, discard the supernatant; ④ add distilled water to wash, centrifuge for 5min, discard the supernatant. Repeat the washing of the residue 6 times, and check the pH at the end to ensure that the washing is neutral; the residue is finally washed with acetic acid buffer, washed once with 10mL 0.2mol / L acetic acid buffer with pH 4.8, and waits for the enzymatic hydrolysis reaction.

Embodiment 3

[0061] In this embodiment, rice is used as the biomass material raw material, and all the other steps are the same as in Example 1, except that the gas explosion time is 16 minutes.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap