Aminated Fe3O4@SiO2 nanoparticles and application thereof in polypyrrole modified microbial fuel cell anode

A nanoparticle and amination technology, which is applied in the fields of biochemical fuel cells, battery electrodes, electrochemical biocombination treatment, etc., can solve the problems of limiting large-scale practical application, low output power density of microbial fuel cells, etc., and achieve remarkable product effects. , easy to process, improve the effect of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, this example provides the preparation method of aminated Fe3O4@SiO2 nanoparticles

[0038] First, accurately weigh 13.5145g FeCl3·6H2O in a beaker, dissolve it with a mixed solution of BF4 and H2O with a volume ratio of 1:1, and set the volume to 50mL to obtain a 1.00mol / L FeCl3 solution.

[0039] Accurately weigh 6.9505g FeSO4·7H2O in a beaker, dissolve it with a mixed solution of [Bmim]BF4 and H2O with a volume ratio of 1:1, and set the volume to 50mL to obtain a 0.50mol / L FeSO4 solution.

[0040] Take 25mL of 1.00mol / L FeCl3 solution and 0.50mol / L FeSO4 solution in a beaker and mix evenly, while heating with a water bath and keeping it at 30°C. Slowly add about 50mL of 1.00mol / L NaOH solution dropwise under stirring conditions, then add about 10mL of concentrated ammonia water dropwise until the solution turns completely black, measure the pH to about 10.0, until the solution turns completely black, then continue to add a small amount of sodium hydroxide d...

Embodiment 2

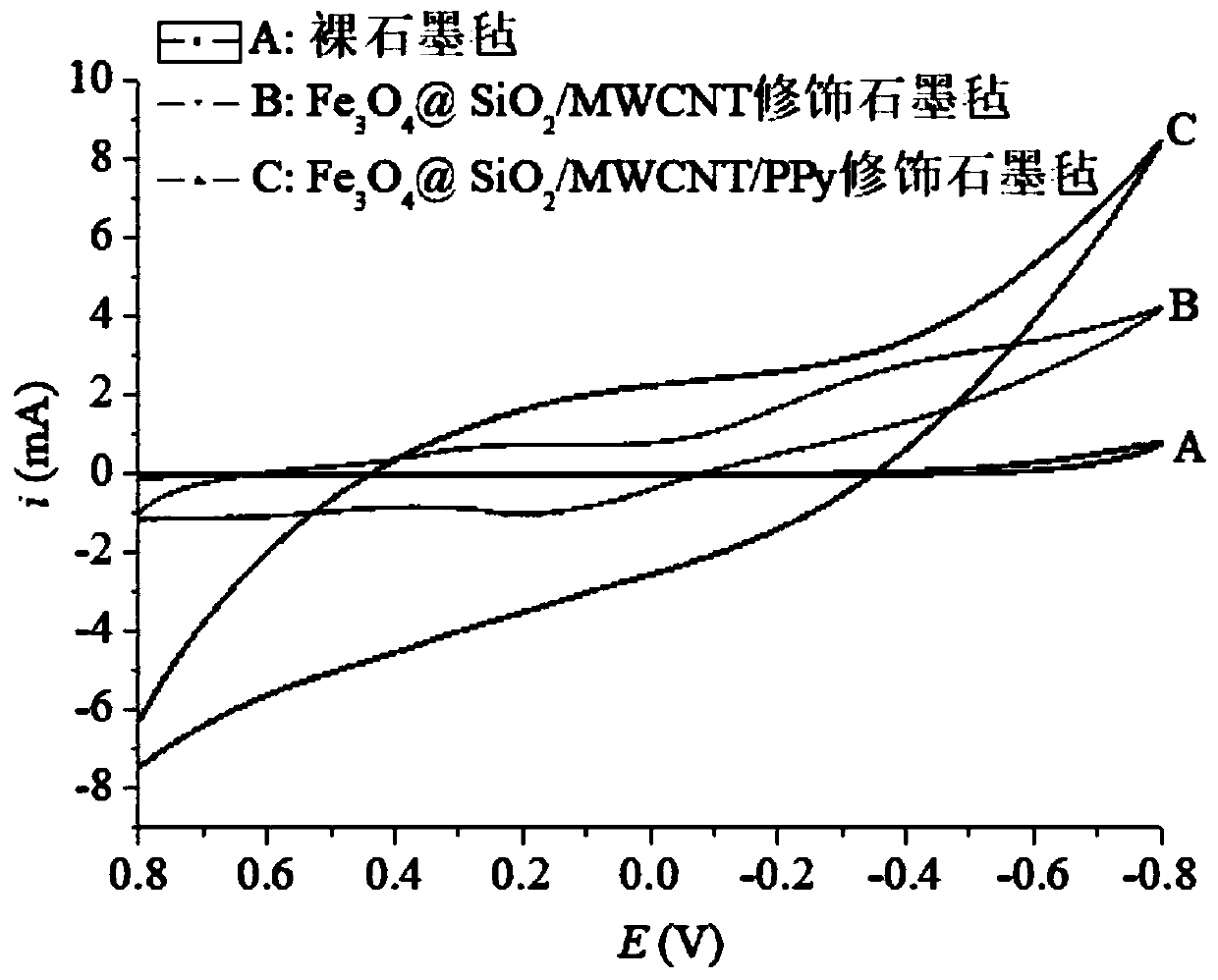

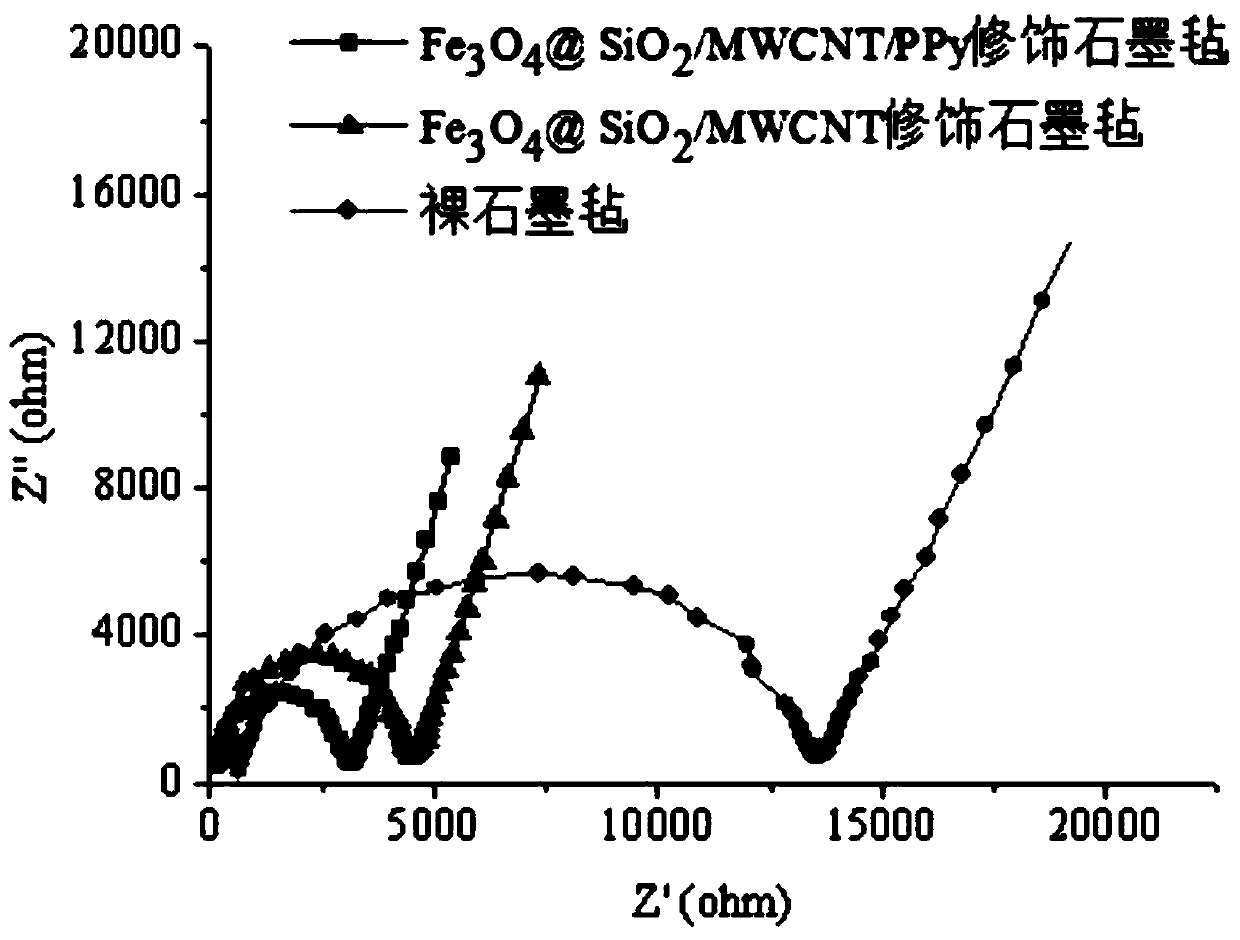

[0043] Example 2 This example provides a polypyrrole-modified microbial fuel cell anode using the above-mentioned aminated Fe3O4@SiO2 nanoparticles

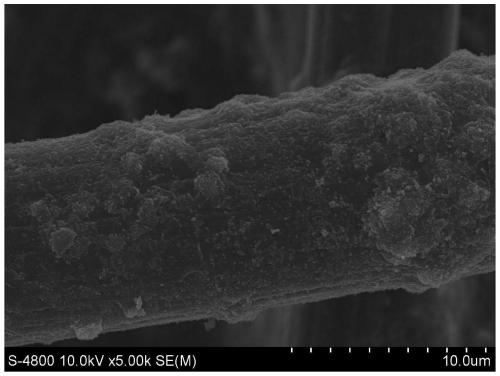

[0044] Cut the graphite felt into the required size, and wash it with 1mol / L HCl, 1mol / L NaOH, 3% H2O2, acetone, and deionized water respectively at 50°C. Let it dry for later use. Fix the graphite rod on one side of the graphite felt with conductive silver glue, seal and fix it with epoxy resin glue, and dry at room temperature. Accurately weigh Fe3O4@SiO2-NH2 nanoparticles and washed and dried MWCNT-COOH according to the mass ratio of 3:7, and grind them in a mortar to mix the two evenly, and due to the hydrogen bond between the amino group and the carboxyl group , the two can be combined into Fe3O4@SiO2 / MWCNT nanocomposites. According to the ratio of 10mg mixture dispersed in 1mL 1% Nafion / ethanol solution, ultrasonic dispersion is uniform, every 500μL is dropped on 1cm 2 graphite felt, the suspension is coated on both sides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com