A kind of synthesis method of rgo/mwcnt/ha/fe3o4 composite material

A synthesis method and composite material technology, applied in the field of composite material synthesis, can solve problems that have not yet appeared, achieve good biological activity and biocompatibility, simple method, and expand the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

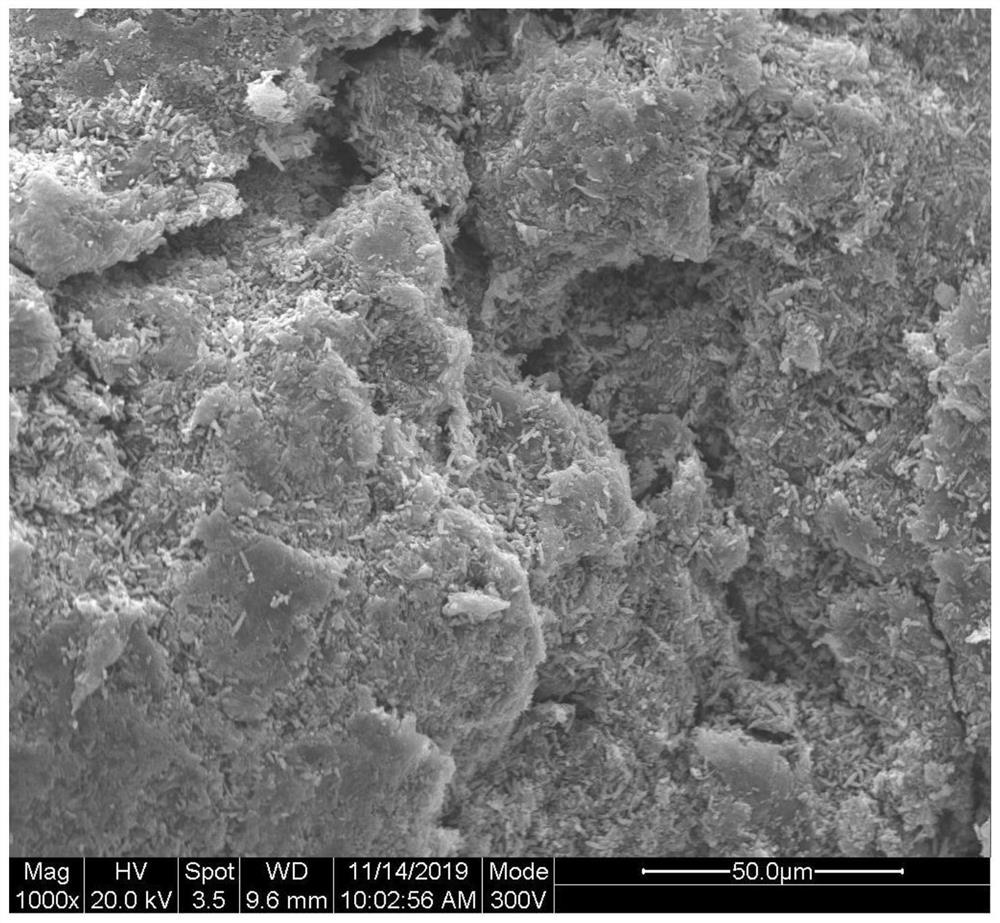

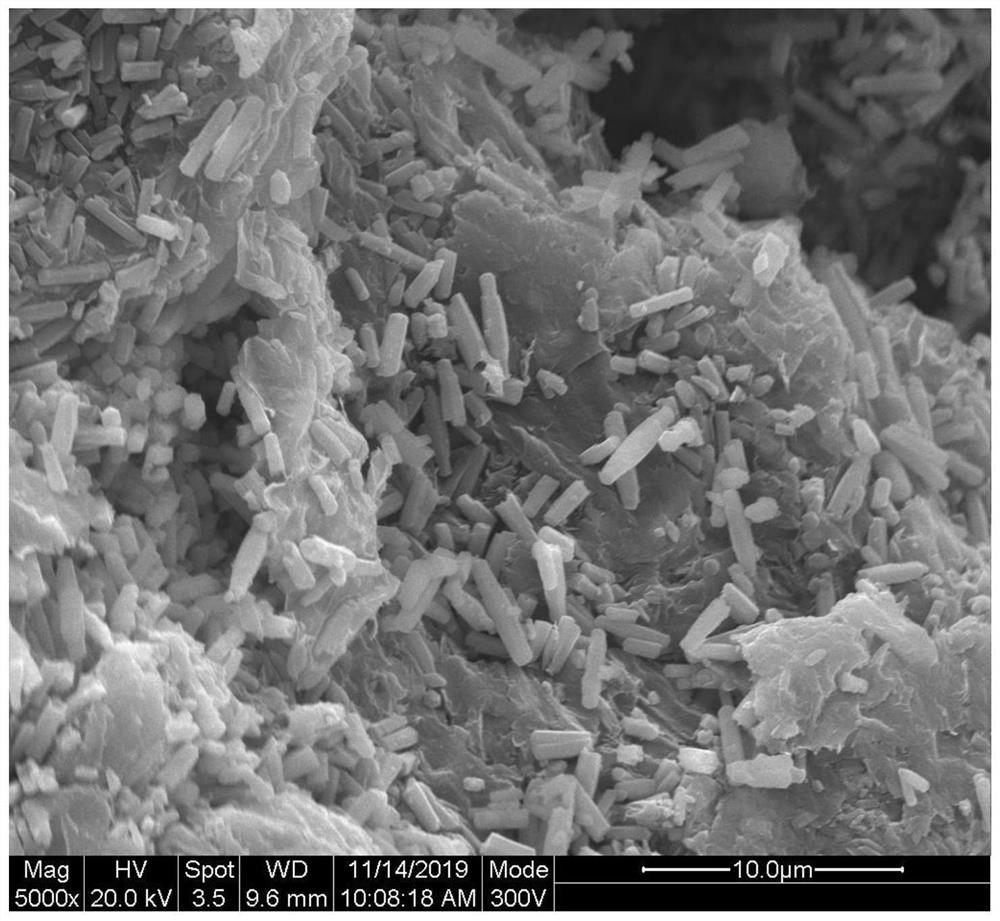

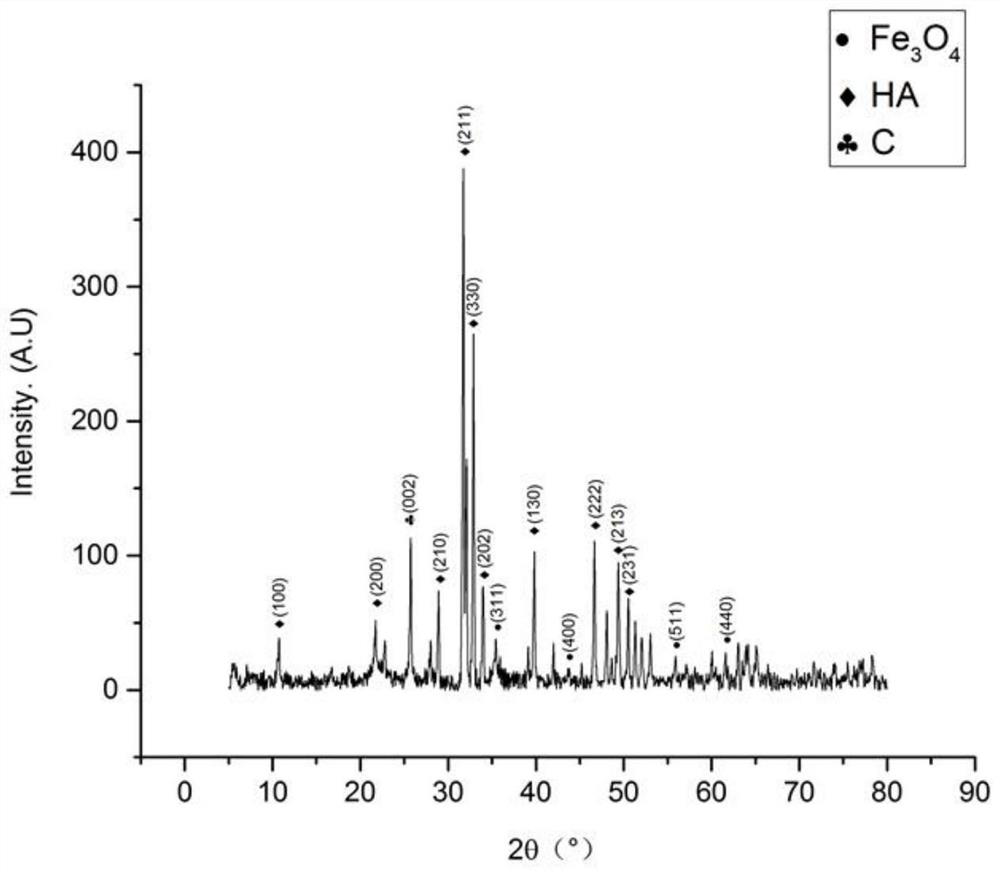

Image

Examples

Embodiment 1

[0040] A kind of RGO / MWCNT / HA / Fe 3 o 4 The synthetic method of composite material, comprises the following steps:

[0041] S1. Weigh 200mg of diionic surfactant (trisulfopropyl tetradecyl dimethyl betaine), which is divided into reactant I and reactant II;

[0042] S2. Dissolve the reactant I in 400mL of deionized water, and stir evenly with a magnetic force to obtain a surfactant solution;

[0043] S3. Mix and grind the reactant II with 50 mg MWCNT (multi-walled carbon nanotubes), and then add it to the above-mentioned surfactant solution to obtain a MWCNT dispersion, which is set aside;

[0044] S4. Dissolve 150mg of GO in 300mL of deionized water, and stir evenly with magnetic force to obtain the mixed solution I;

[0045] S5. Slowly add the above-mentioned MWCNT dispersion liquid to the mixed liquid I at a rate of 60 rpm / min through a constant flow pump. After all the addition, the electrostatic self-assembly reaction is carried out for 3 hours, and the MWCNTs are uniform...

Embodiment 2

[0054] A kind of RGO / MWCNT / HA / Fe 3 o 4 The synthetic method of composite material, comprises the following steps:

[0055] S1. Weigh 100mg of diionic surfactant (trisulfopropyltetradecyl dimethyl betaine), which is equally divided into reactant I and reactant II;

[0056] S2. Dissolve the reactant I in 200mL deionized water, and stir evenly with a magnetic force to obtain a surfactant solution;

[0057] S3. Mix and grind the reactant II with 50 mg MWCNT (multi-walled carbon nanotubes), and then add it to the above-mentioned surfactant solution to obtain a MWCNT dispersion, which is set aside;

[0058] S4. Dissolve 150mg of GO in 300mL of deionized water, and stir evenly with magnetic force to obtain the mixed solution I;

[0059] S5. Slowly add the above-mentioned MWCNT dispersion liquid to the mixed liquid I at a rate of 60 rpm / min through a constant flow pump. After all the addition, conduct an electrostatic self-assembly reaction for 2 hours. After the MWCNTs are evenly ...

Embodiment 3

[0068] A kind of RGO / MWCNT / HA / Fe 3 o 4 The synthetic method of composite material, comprises the following steps:

[0069] S1. Weigh 150mg of diionic surfactant (trisulfopropyl tetradecyl dimethyl betaine), which is equally divided into reactant I and reactant II;

[0070] S2. Dissolve the reactant I in 300mL deionized water, and stir evenly with a magnetic force to obtain a surfactant solution;

[0071] S3. Mix and grind the reactant II with 50 mg MWCNT (multi-walled carbon nanotubes), and then add it to the above-mentioned surfactant solution to obtain a MWCNT dispersion, which is set aside;

[0072] S4. Dissolve 150mg of GO in 300mL of deionized water, and stir evenly with magnetic force to obtain the mixed solution I;

[0073] S5. Slowly add the above-mentioned MWCNT dispersion liquid to the mixed liquid I at a rate of 60 rpm / min through a constant flow pump. After all the addition, conduct an electrostatic self-assembly reaction for 4 hours, and wait until the MWCNTs a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com