Multilayer microneedle array and preparation method thereof

A microneedle array and single-layer technology, applied in the field of biomedical materials, can solve the problems of great influence on adhesion ability, drop of needle tip, complicated preparation method, etc., and achieve good tissue adhesion, strong repeatability, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

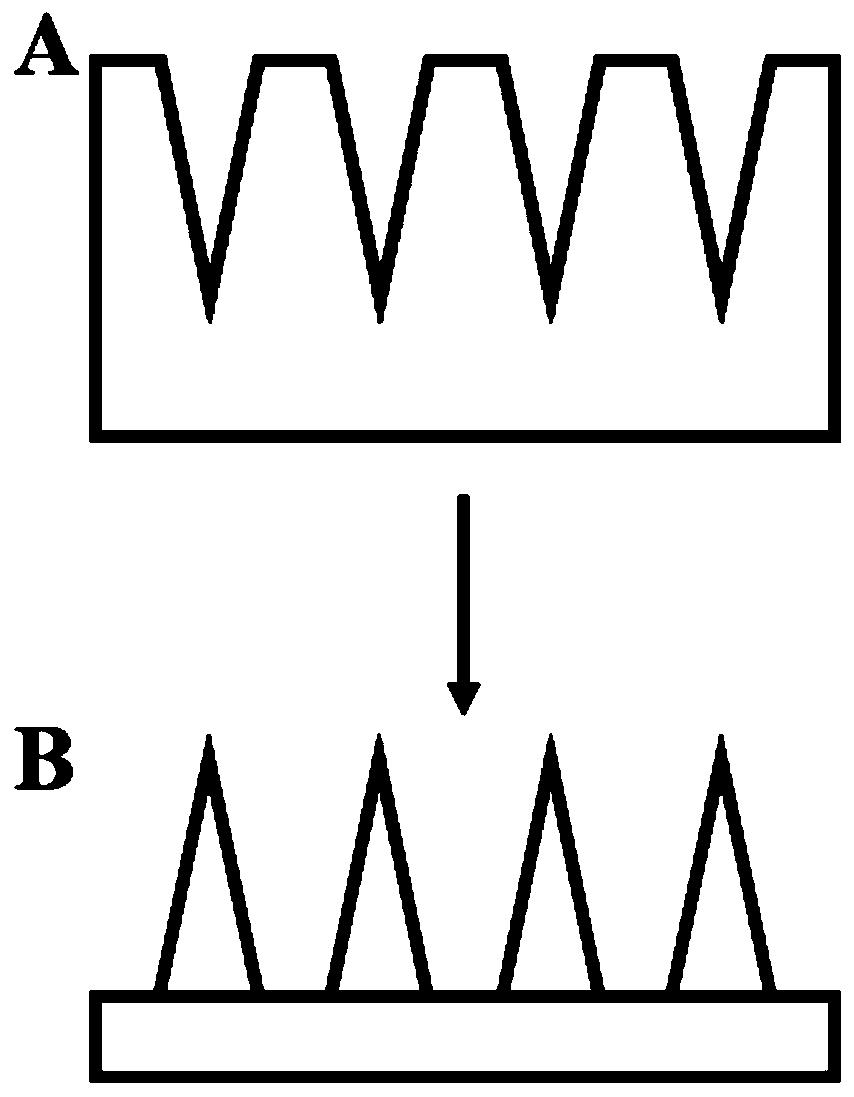

[0030] Preparation of monolayer microneedle arrays:

[0031] An aqueous solution containing 50% by volume of polyethylene glycol diacrylate and 1% by volume of 2-hydroxy-2-methylpropiophenone was prepared as a raw material solution. Use a pipette gun to drop 500 microliters of the raw material solution on the polydimethylsiloxane template, and vacuum it for 2 minutes, so that the raw material solution is fully filled in the conical holes of the template (the size of the holes is 400 microns apart, and the depth 500 microns, 350 microns in diameter). After 30 seconds of UV treatment, the raw material solution is cured and then carefully peeled off from the polydimethylsiloxane template, and finally a single-layer microneedle array can be obtained, as figure 1 shown.

Embodiment 2

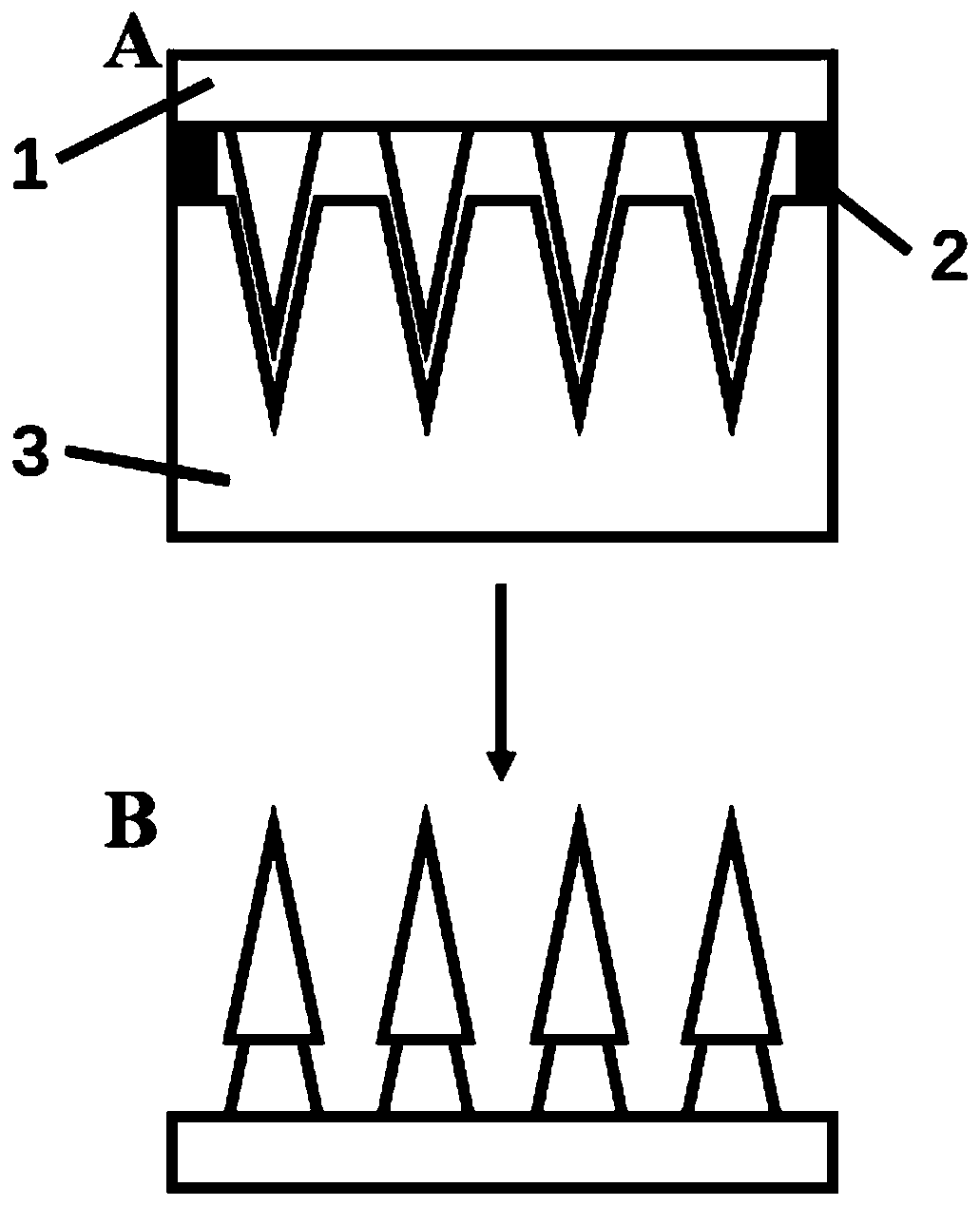

[0033] Preparation of double-layer microneedle arrays:

[0034] An aqueous solution containing 50% by volume of polyethylene glycol diacrylate and 1% by volume of 2-hydroxy-2-methylpropiophenone was prepared as a raw material solution. Use a pipette gun to drop 500 microliters of the raw material solution on the polydimethylsiloxane template, and vacuum it for 2 minutes, so that the raw material solution is fully filled in the conical holes of the template (the size of the holes is 400 microns apart, and the depth 500 microns, 350 microns in diameter). After 30 seconds of UV treatment, the raw material solution was cured and then carefully peeled off from the polydimethylsiloxane template to obtain a single-layer microneedle array.

[0035] 500 microliters of the raw material solution was added dropwise on the polydimethylsiloxane template with a pipette gun again, and treated in vacuum for 2 minutes, so that the raw material solution was fully filled in the conical holes of ...

Embodiment 3

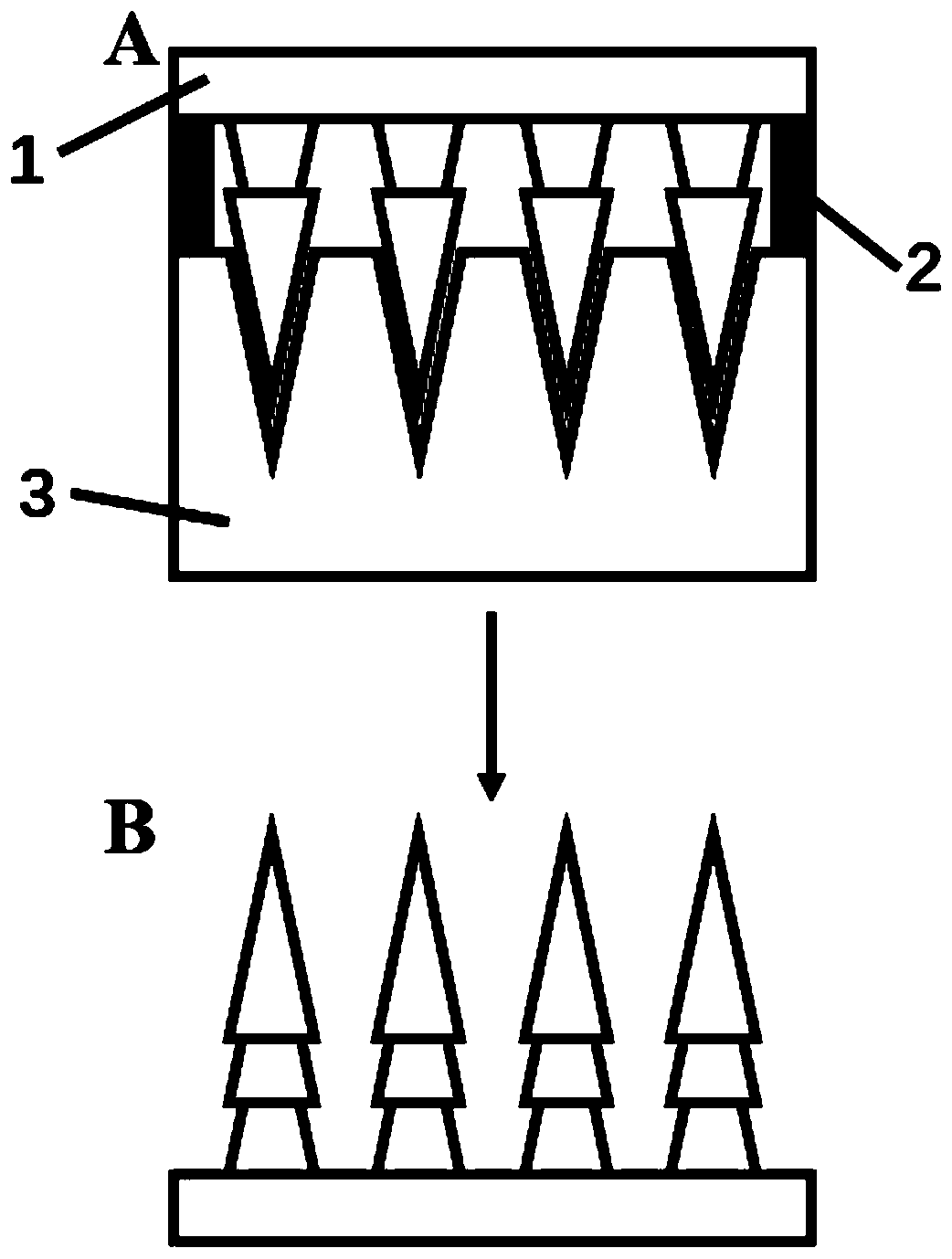

[0037] Preparation of three-layer microneedle array:

[0038] An aqueous solution containing 30% by volume of methacrylate gelatin and 1% by volume of 2-hydroxy-2-methylpropiophenone was prepared as a raw material solution. Use a pipette gun to drop 500 microliters of the raw material solution on the polydimethylsiloxane template, and vacuum it for 2 minutes, so that the raw material solution is fully filled in the conical holes of the template (the size of the holes is 400 microns apart, and the depth 500 microns, 350 microns in diameter). After 45 seconds of UV treatment, the raw material solution was cured and then carefully peeled off from the polydimethylsiloxane template to obtain a single-layer microneedle array.

[0039] Use a pipette gun to drop 500 microliters of the raw material solution onto the polydimethylsiloxane template, and treat with vacuum for 2 minutes, so that the raw material solution is fully filled in the conical holes of the template. Then, the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com