Production method and production equipment of polypropylene melt-blown materials

A polypropylene melt-blown and production method technology, applied in the field of polypropylene special materials, can solve the problems of uneven polypropylene melt-blown material, melt-blown fluctuation, incomplete reaction, etc., achieve uniform flow rate, ensure full mixing and full reaction , the effect of good quality uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

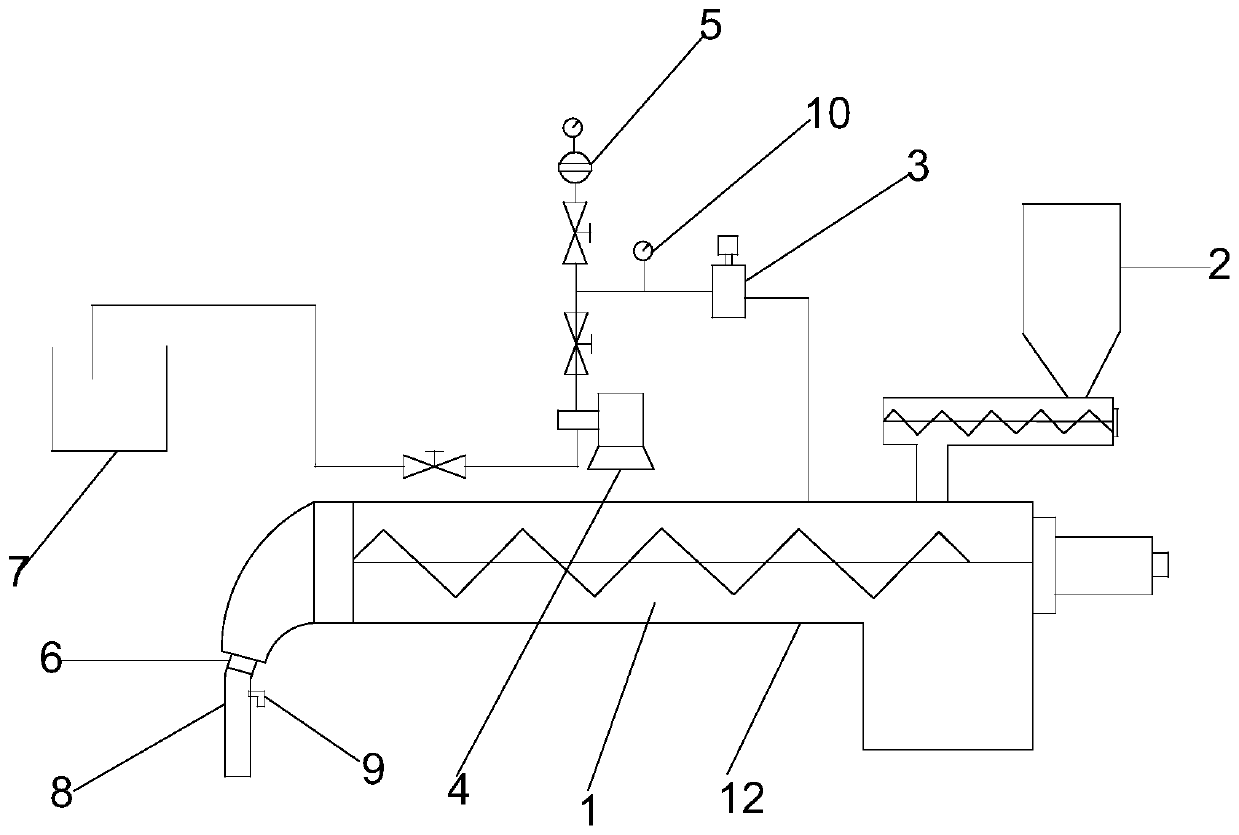

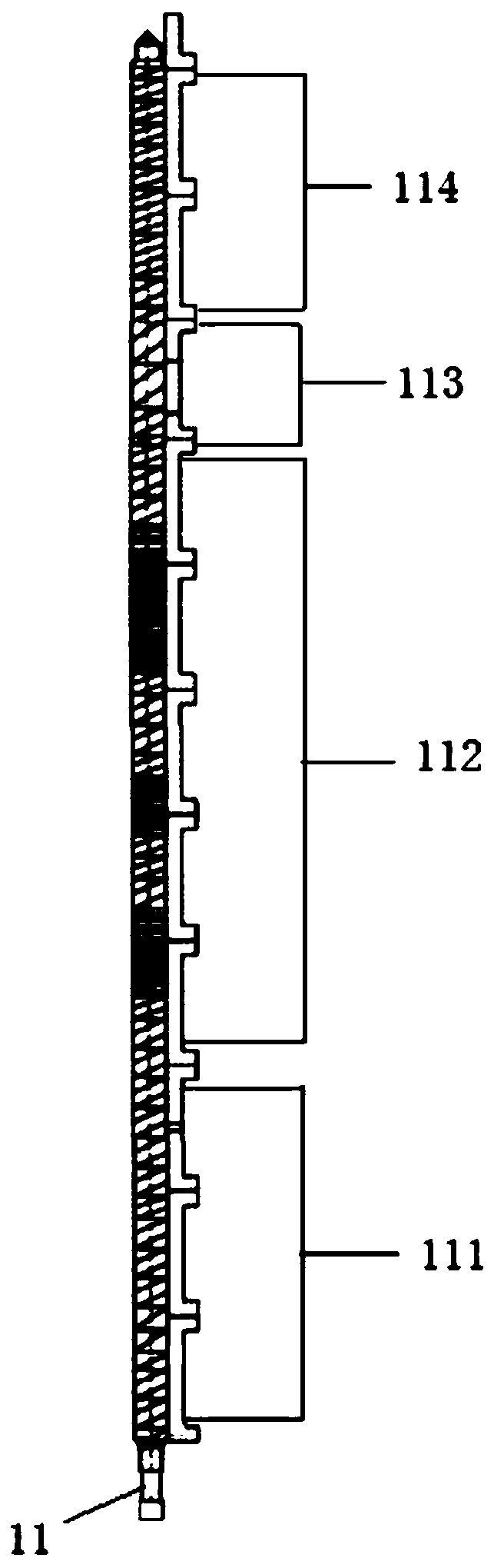

Method used

Image

Examples

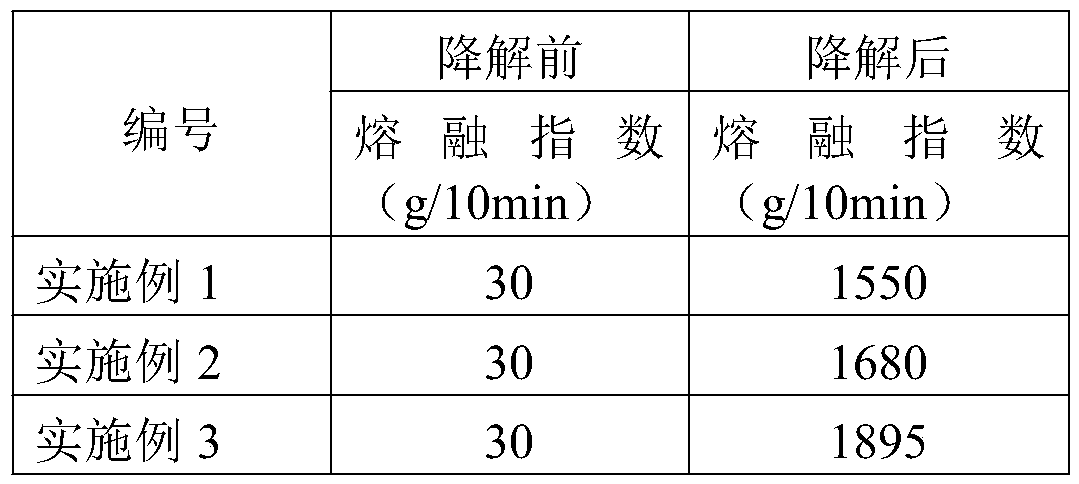

Embodiment 1

[0043] A kind of production method of polypropylene meltblown material that embodiment 1 provides, comprises the steps:

[0044] (1) Prepare raw materials: The raw materials for the preparation of special materials for polypropylene melt-blown non-woven fabrics include the following raw materials in terms of parts by mass: 100 parts of polypropylene, 0.1 part of light stabilizer, 0.2 part of composite antioxidant, 0.2 part of calcium stearate part and 0.3 part of degrading agent; In this embodiment 1, degrading agent is dicumyl peroxide; Composite antioxidant is made of 2,6-di-tert-butyl p-cresol and tetrakis [(3,5-di tert-Butyl-4-Hydroxycinnamic Acid Subtide]methane compound;

[0045] (2) Mixed raw materials: polypropylene, light stabilizer, composite antioxidant and calcium stearate are put into the mixer and stirred and mixed, the stirring speed of the mixer is 200r / min, the stirring time is 25 minutes, and the stirring temperature is 30°C, after stirring evenly, the raw m...

Embodiment 2

[0050] A kind of production method of polypropylene melt-blown material that embodiment 2 provides, comprises the steps:

[0051] (1) Preparation of raw materials: The raw materials for the preparation of special materials for polypropylene melt-blown non-woven fabrics include the following raw materials in terms of parts by mass: 100 parts of polypropylene, 0.3 parts of light stabilizer, 0.1 part of composite antioxidant, and 0.3 parts of calcium stearate part and 1.0 part of degradation agent; in this embodiment 2, degradation agent is dicumyl peroxide; Composite antioxidant is made of 2,6-di-tert-butyl p-cresol and tetrakis [(3,5-di tert-Butyl-4-Hydroxycinnamic Acid Subtide]methane compound;

[0052] (2) Mixed raw materials: polypropylene, light stabilizer, composite antioxidant and calcium stearate are put into the mixer and stirred and mixed, the stirring speed of the mixer is 200r / min, the stirring time is 25 minutes, and the stirring temperature is 30°C, after stirring...

Embodiment 3

[0057] A kind of production method of polypropylene melt-blown material that embodiment 3 provides, comprises the steps:

[0058] (1) Preparation of raw materials: The raw materials for the preparation of special materials for polypropylene melt-blown non-woven fabrics include the following raw materials in terms of parts by mass: 100 parts of polypropylene, 0.5 parts of light stabilizer, 0.3 parts of composite antioxidant, and 0.5 parts of calcium stearate Part and 1.5 parts of degrading agent; In this embodiment 3, degrading agent is the mixture that is made up of dicumyl peroxide, benzoyl peroxide and di-tert-butyl peroxide; Composite antioxidant is made of 2,6 - Di-tert-butyl-p-cresol and tetrakis [(3,5-di-tert-butyl-4-hydroxy oxycinnamic acid subtallow) methane;

[0059] (2) Mixed raw materials: polypropylene, light stabilizer, composite antioxidant and calcium stearate are put into the mixer and stirred and mixed, the stirring speed of the mixer is 200r / min, the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com