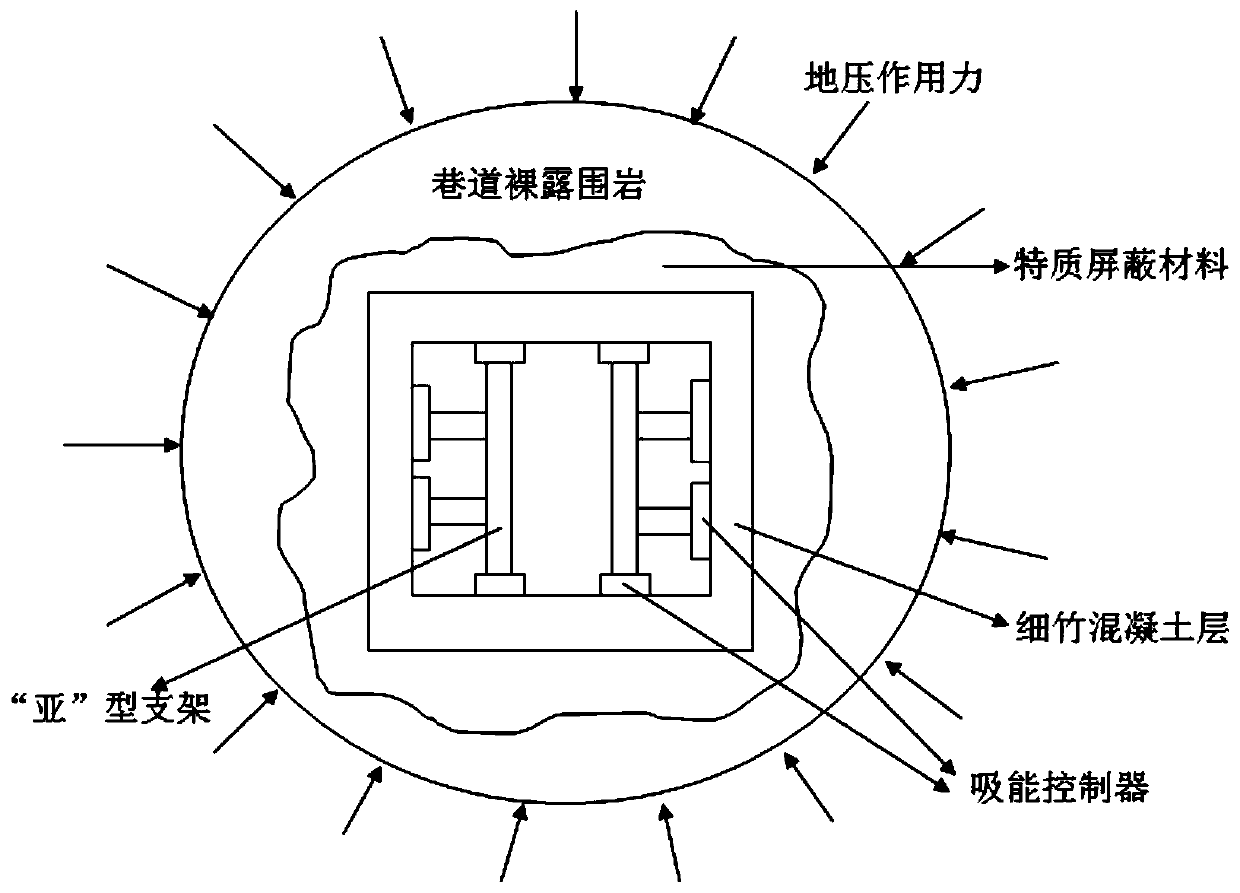

Roadway or tunnel surrounding rock shielding protection structure and method

A technology of shielding protection and protective structure, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve strong support and protection capabilities, optimized protection effects, and a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

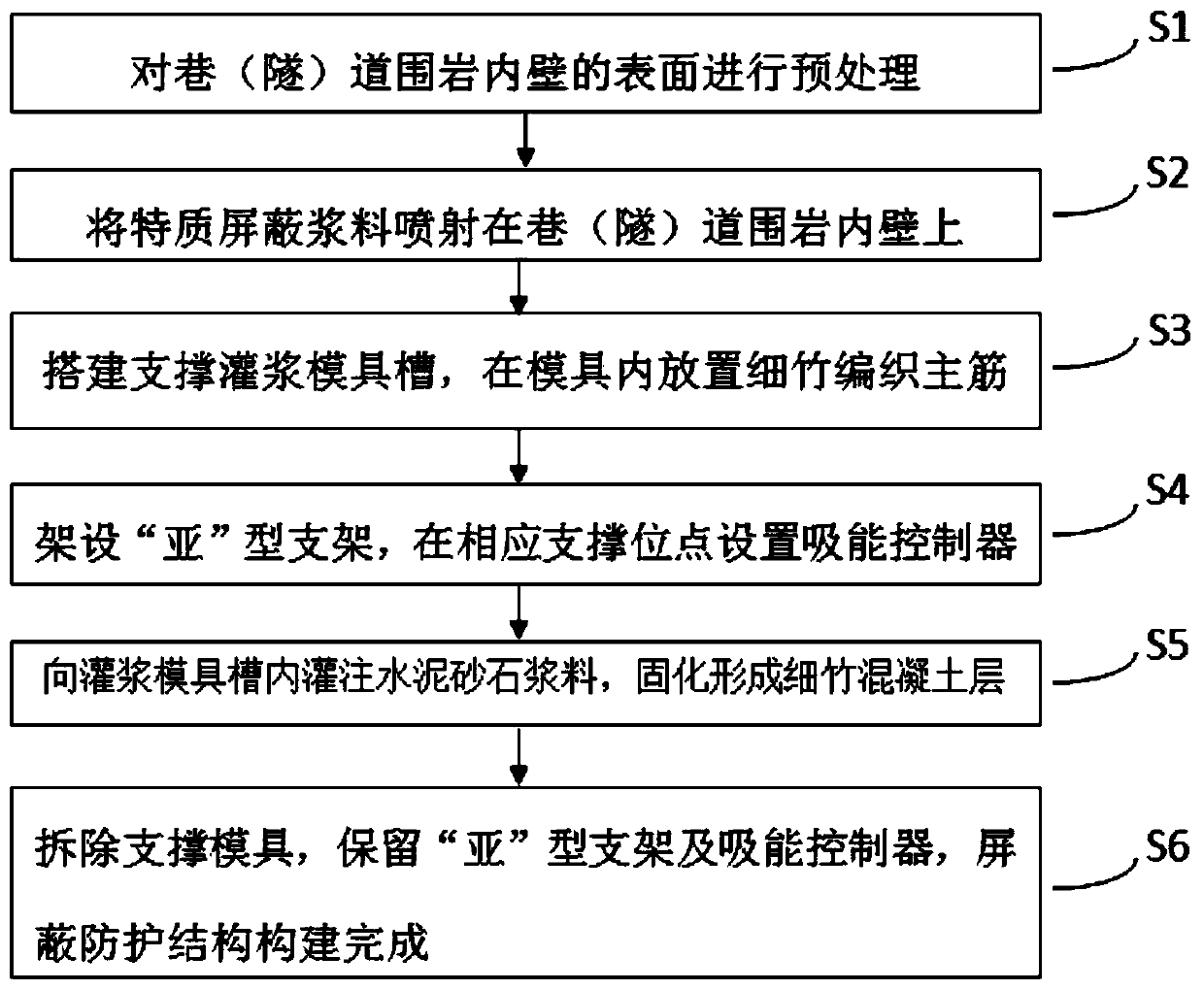

Method used

Image

Examples

Embodiment 1

[0051]Special shielding material raw materials include the following components by weight: 8 parts of silicon carbide, 4.5 parts of graphite, 2 parts of titanium powder, 4.5 parts of aluminum powder, 42 parts of steel slag, 35 parts of fly ash, 1.5 parts of calcium carbonate and methyl fiber Vegetable 2.5 parts;

[0052] Special shielding material preparation steps:

[0053] S2.1) Weigh each material respectively according to the above-mentioned characteristic shielding material composition ratio;

[0054] S2.2) putting silicon carbide, aluminum powder, steel slag, and fly ash into a ball mill for ball milling for 11 hours to obtain a mixed powder;

[0055] S2.3) putting graphite and titanium powder into a ball mill and milling for 7 hours to obtain a mixed powder;

[0056] S2.4) heating the mixed powder after ball milling in step S2.2) to 1000° C. to melt to form a melt;

[0057] S2.5) Put the mixed powder after ball milling in step S2.3) into the melt described in step S2...

Embodiment 2

[0069] Shock wave experiment:

[0070] Required equipment: pressure sensor (to measure the peak pressure of the shielding protection material under the action of shock stress wave), support body (to support the fixed test sample), shock stress wave barrier device (to detect the impact of local stress wave shock), explosives (select spherical TNT ), explosive suspension brackets and other related equipment.

[0071] Dispersion test of special shielding material board on local stress wave impact: the test sample is 20cm thick bamboo concrete board, 10cm thick special shielding material board, length and width are 100cm, 600gB explosive, test distance 1 meter, special shielding material board is in front A barrier baffle is set at 1cm, and a circular hole with a radius of 5cm is left in the center of the barrier baffle. The barrier baffle and the thin bamboo concrete slab are fixed by the support body, and the special shielding material board is attached to the thin bamboo concre...

Embodiment 3

[0077] Experiments on the relationship between the dispersion effect of the special shielding material plate on the impact pressure of the stress wave and the composition of the raw materials:

[0078] Test method is with embodiment 2;

[0079] Through the raw material composition and ratio orthogonal test, the two components of titanium and aluminum in the raw material have a significant impact on the stress wave shock dispersion effect of the special shielding material, and when the weight ratio is close to 5:9, the total content is close to 7±3%. , the dispersion effect is the best, can reach more than 85%, which is at least 5% higher than other optimized ratio combinations, so the titanium powder and aluminum powder in the special shielding material raw materials are composed according to the following parts by weight: titanium powder 2-3 parts, 4-5 parts of aluminum powder, and other components according to the following parts by weight: 8-10 parts of silicon carbide, 3-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com