Immersion phase change liquid cooling system of laser

A phase change liquid and laser technology, applied in the field of lasers, can solve the problems of increased heat dissipation power consumption, laser damage, and high heat dissipation system pressure, and achieve the effects of improving heat dissipation efficiency, solving heat dissipation problems, and strong environmental applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

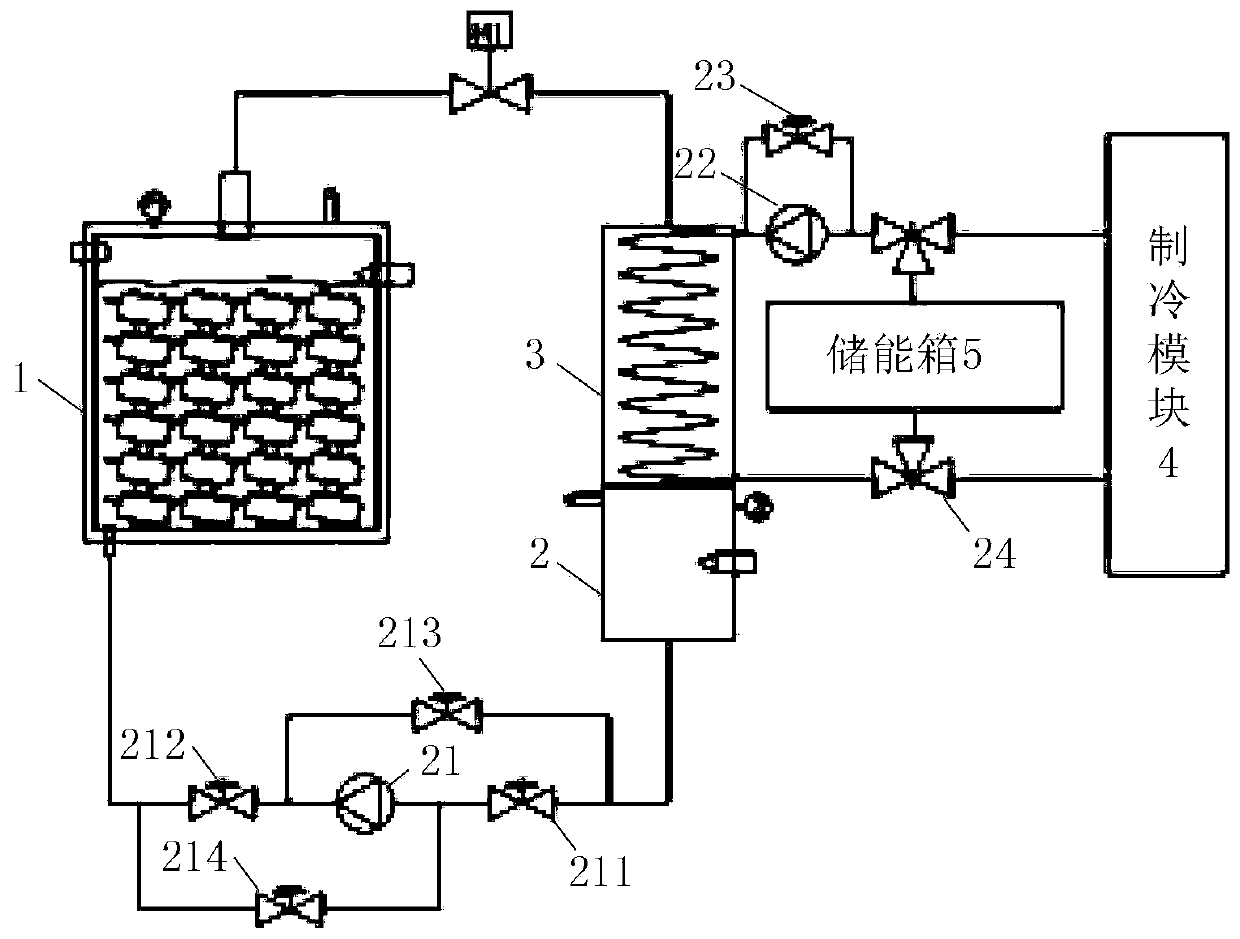

[0053] In this embodiment, the operation mode of the system is set to include cold storage mode, front operation mode, operation mode and stop mode. Among them, the cold storage mode is that the refrigeration module 4 supplies cold energy to the energy storage box 5, which is the laser knife box 1 (laser Module 11) Prepare for heat dissipation; the previous operation mode is to cool down the entire system when it is determined that the ambient temperature is greater than 25°C; the operation mode is that the system cools down the laser knife box 1 for heat dissipation.

[0054] The refrigeration device also includes: a refrigeration module 4 and a bypass valve 23; the water injection end of the refrigeration module 4 is connected to the water inlet end of the condenser 3 through the bypass valve 23, and the return water end of the refrigeration module 4 is connected to the water outlet of the condenser 3 At the end, the refrigeration module 4 is used to perform the first refrigerat...

Embodiment 2

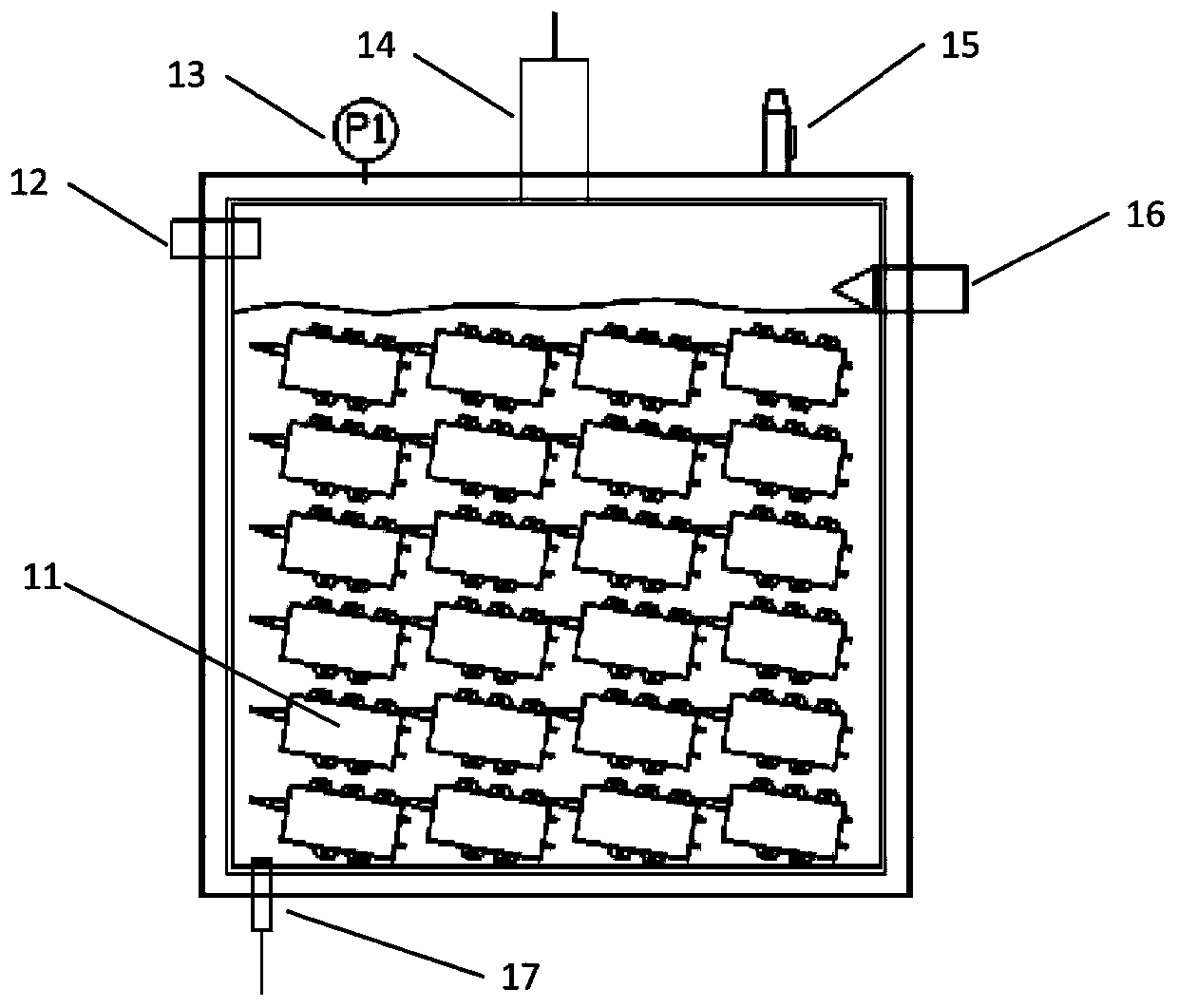

[0066] Set the heating power of a single laser module to 200W, 24 as a group of arrays in the laser knife box 1, the total heat is 4800W, the atmospheric pressure evaporation temperature of the refrigerant is 25°C, and the evaporation phase change enthalpy is 200J / g.

[0067] The heating surface is immersed in the refrigerant. The first liquid level sensor 16 detects the height of the liquid level in the tank. When the liquid level is low, the first pump 21 starts to supply liquid from the liquid inlet 17 and stops when the liquid level reaches the heat dissipation requirement. .

[0068] The first pressure sensor 13 detects the pressure inside the laser knife box 1. When the gauge pressure is between -30kpa and 30kpa, the flow rate of the second pump 22 is controlled to adjust the condensation rate of the gaseous refrigerant to achieve the purpose of constant pressure. When the gauge pressure is lower than -30kpa or higher than 30kpa, the first pressure relief valve 5 is activated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com