Method for relieving successive cropping obstacle of watermelons

A continuous cropping obstacle, watermelon technology, applied in the field of alleviating the continuous cropping obstacle of watermelon, can solve the problems of the negative impact of soil or crops, the long cycle of screening disease-resistant varieties, the impact on fruit quality, etc. The effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

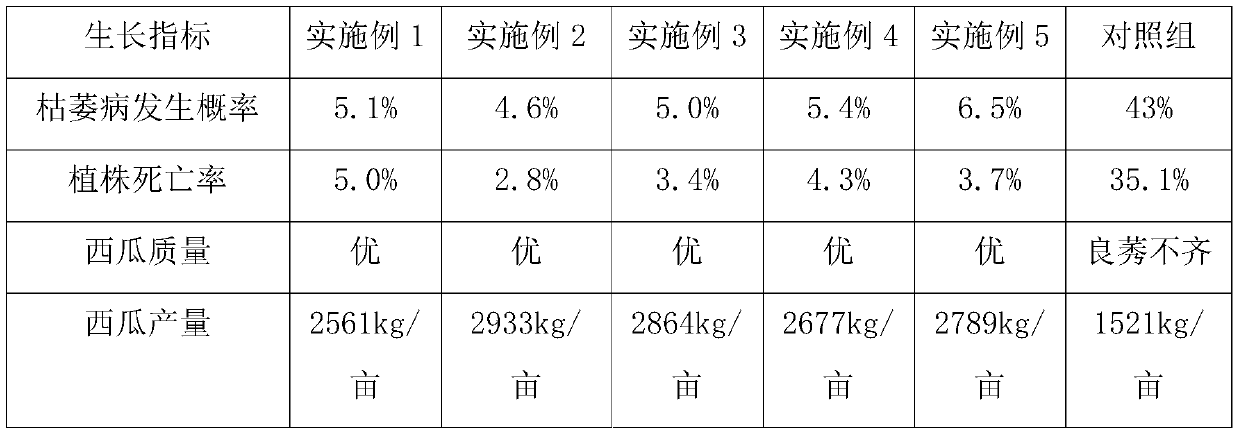

Examples

Embodiment 1

[0025] The preparation of the corncob meal in the soil conditioner of the present embodiment is as follows:

[0026] Dry the corncob and pulverize it to pass through a 200-mesh sieve. According to the mass ratio of corncob and sodium hydroxide to be 1:0.2, respectively weigh the sieved corncob powder and sodium hydroxide and mix well, and then add nicotinamide. Amine and 1-(3-hydroxy-n-propyl) cyclopentanol are ground and mixed. The amount of nicotinamide added is 2% of the mass of the sieved corncob powder. 1-(3-hydroxy-n-propyl) ring The amount of amyl alcohol added is 1% of the mass of the sieved corncob powder, then transferred to a tube furnace, carbonized by oxygen for 6 hours at a temperature of 650° C., and cooled to room temperature to obtain carbonized corncob powder.

[0027] The preparation of modified peanut shell powder in soil conditioner is as follows:

[0028] Dry and pulverize the peanut shells, pass through a 200-mesh sieve, add water of 0.6 times the quali...

Embodiment 2

[0038] The preparation of the corncob meal in the soil conditioner of the present embodiment is as follows:

[0039] Dry the corncob and pulverize it to pass through a 500-mesh sieve. According to the mass ratio of corncob and sodium hydroxide to be 1:0.2, respectively weigh the sieved corncob powder and sodium hydroxide and mix well, and then add nicotinamide. Amine and 1-(3-hydroxy-n-propyl) cyclopentanol are ground and mixed. The amount of nicotinamide added is 2% of the mass of the sieved corncob powder. 1-(3-hydroxy-n-propyl) ring The amount of amyl alcohol added is 1% of the mass of the sieved corncob powder, then transferred to a tube furnace, carbonized by oxygen isolation at a temperature of 700° C. for 5 hours, and cooled to room temperature to obtain carbonized corncob powder.

[0040] The preparation of modified peanut shell powder in soil conditioner is as follows:

[0041]Dry and pulverize the peanut shells, pass through a 200-mesh sieve, add water with 0.6 time...

Embodiment 3

[0051] The preparation of the corncob meal in the soil conditioner of the present embodiment is as follows:

[0052] Dry the corncob and pulverize it to pass through a 200-mesh sieve. According to the mass ratio of corncob and sodium hydroxide to be 1:0.2, respectively weigh the sieved corncob powder and sodium hydroxide and mix well, and then add nicotinamide. Amine and 1-(3-hydroxy-n-propyl) cyclopentanol are ground and mixed. The amount of nicotinamide added is 2% of the mass of the sieved corncob powder. 1-(3-hydroxy-n-propyl) ring The amount of amyl alcohol added is 1% of the mass of the sieved corncob powder, then transferred to a tube furnace, carbonized by oxygen for 4 hours at a temperature of 750° C., and cooled to room temperature to obtain carbonized corncob powder.

[0053] The preparation of modified peanut shell powder in soil conditioner is as follows:

[0054] Dry and pulverize the peanut shells, pass through a 200-mesh sieve, add water with 0.6 times the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com