Synchronous methanogenesis and aerobic methane oxidation coupling denitrification process control method

An oxidation coupling, aerobic methane technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water treatment parameter control, etc., can solve problems such as high safety risks, high operating costs, and difficult operations, and achieve The effect of high removal efficiency, promotion of mass transfer efficiency, and prolongation of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

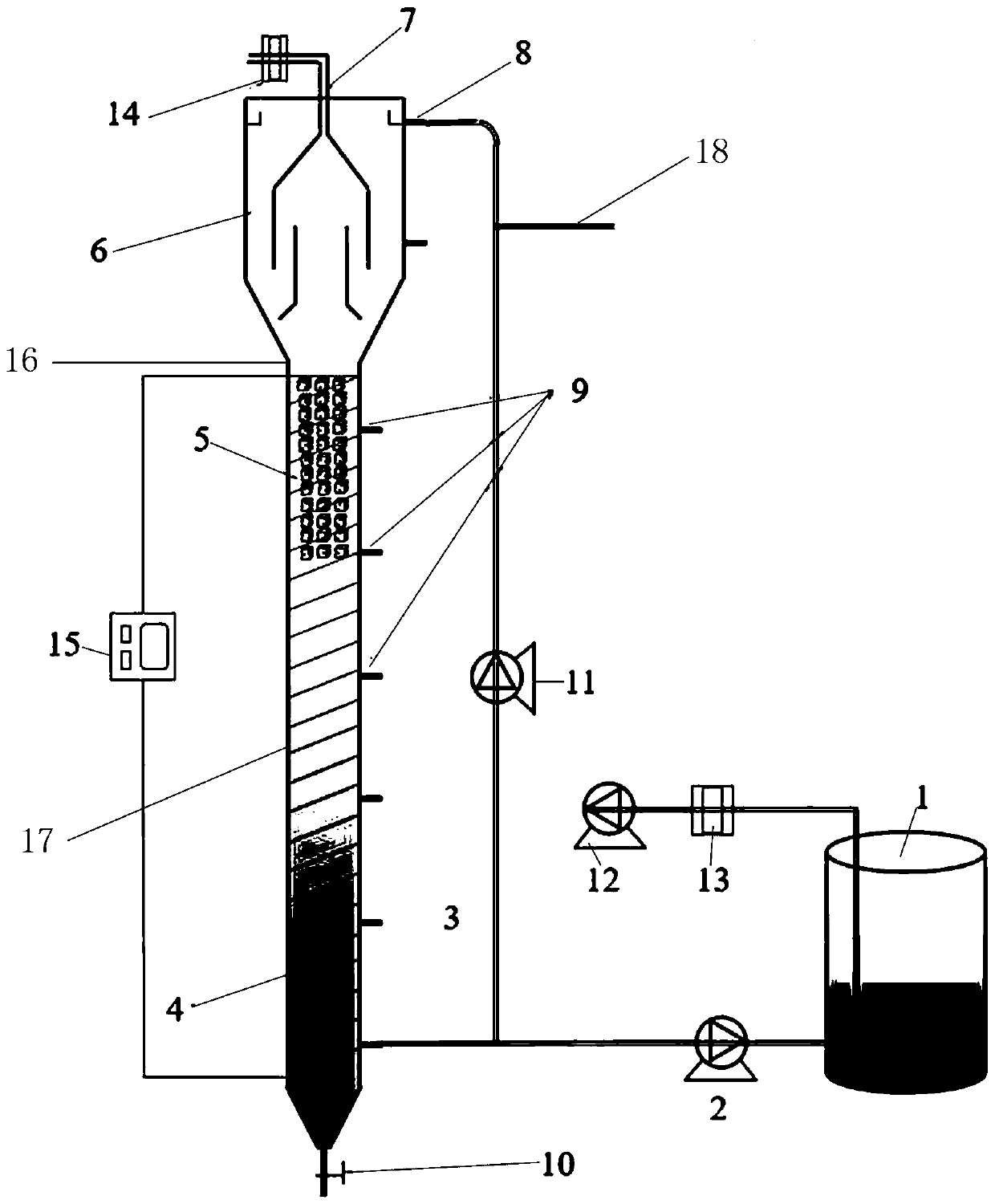

[0038] A method for controlling synchronous methane production and aerobic methane oxidation coupling denitrification process, comprising the following steps:

[0039] (1) The establishment of a reaction system includes: an inlet water adjustment tank, an inlet water peristaltic pump, an expanded granular sludge bed biofilm reactor, an internal circulation pump, and an air compressor;

[0040] The expanded granular sludge bed biofilm reactor includes two parts: the main reaction area and the three-phase separator, the volume ratio is (1~1.2):1; the lower part of the main reaction area is a granular sludge bed, and the top of the main reaction area is arranged with a fixed packing bed , the fixed packing bed accounts for 50% of the volume of the main reaction zone; the three-phase separator is located at the top of the reactor, and its main function is to settle sludge, separate the treated wastewater and collect methane gas; both the main reaction zone and the three-phase separ...

Embodiment 2

[0054] A method for controlling synchronous methane production and aerobic methane oxidation coupling denitrification process, comprising the following steps:

[0055] (1) The establishment of a reaction system includes: an inlet water adjustment tank, an inlet water peristaltic pump, an expanded granular sludge bed biofilm reactor, an internal circulation pump, and an air compressor;

[0056] The expanded granular sludge bed biofilm reactor includes two parts: the main reaction area and the three-phase separator, the volume ratio is (1~1.2):1; the lower part of the main reaction area is a granular sludge bed, and the top of the main reaction area is arranged with a fixed packing bed , the fixed packing bed accounts for 45% of the volume of the main reaction zone; the three-phase separator is located at the top of the reactor, and its main function is to settle sludge, separate the treated wastewater and collect methane gas; both the main reaction zone and the three-phase separ...

Embodiment 3

[0070] A method for controlling synchronous methane production and aerobic methane oxidation coupling denitrification process, comprising the following steps:

[0071] (1) The establishment of a reaction system includes: an inlet water adjustment tank, an inlet water peristaltic pump, an expanded granular sludge bed biofilm reactor, an internal circulation pump, and an air compressor;

[0072] The expanded granular sludge bed biofilm reactor includes two parts: the main reaction area and the three-phase separator, the volume ratio is (1~1.2):1; the lower part of the main reaction area is a granular sludge bed, and the top of the main reaction area is arranged with a fixed packing bed , the fixed packing bed accounts for 40% of the volume of the main reaction zone; the three-phase separator is located at the top of the reactor, and its main function is to settle sludge, separate the treated wastewater and collect methane gas; both the main reaction zone and the three-phase separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com