A method for inhibiting the decomposition of sodium gluconate in naphthalene-based superplasticizers for large and medium-sized hydropower projects

A high-efficiency water-reducing agent, a large and medium-sized hydropower technology, applied in the field of concrete admixtures, which can solve the impact of Kasong on the mechanical properties and long-term durability of concrete. There is no systematic study, increasing the production cost of water-reducing agent, and the adverse effects of steel corrosion. and other problems, to achieve the effect of low raw material prices, increased concrete costs, and green, healthy and environmentally friendly concepts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

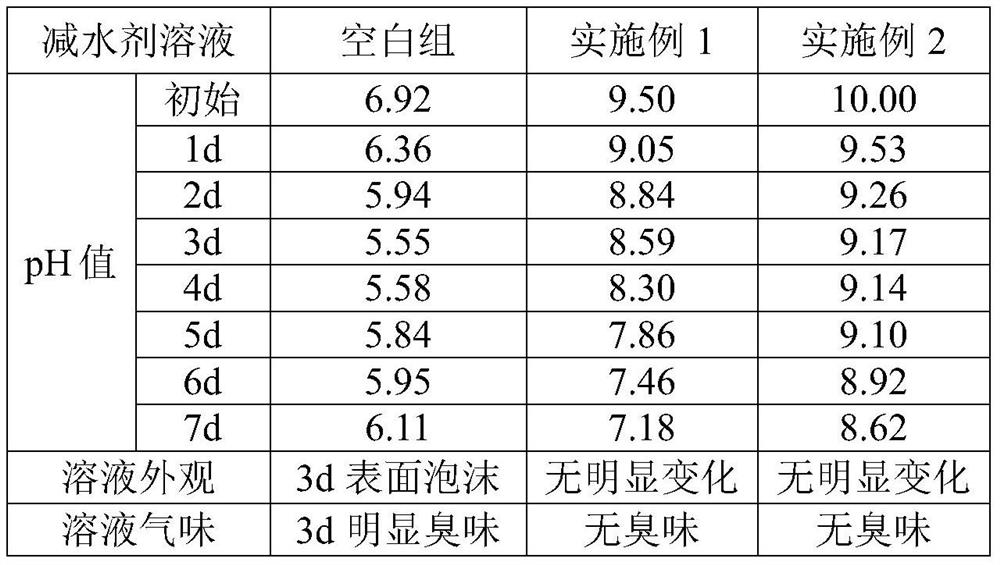

[0041] A method for inhibiting the decomposition of sodium gluconate in a naphthalene-based high-efficiency water-reducer for large and medium-sized hydropower projects. The method is to use a naphthalene-based high-efficiency water-reducer solution to control the pH of the naphthalene-based high-efficiency water-reducer solution to 8.0 to 12.0 The preparation method of the naphthalene series high-efficiency water reducer solution comprises the following steps:

[0042] Step 1: Use concrete mixing water to clean the water reducing agent preparation pool of the mixing system, and keep the preparation pool in a clean and anhydrous state.

[0043] Step 2: Put 5 parts of industrial grade NaOH into the water reducer preparation tank, gradually pour in about 1 / 2 of the tank volume with concrete mixing water to dissolve, and start the stirring device in the preparation tank at a speed of 300 rpm Stirring was continued for 0.75 h, so that the solution mass concentration was about 0.13...

Embodiment 2

[0048] A method for inhibiting the decomposition of sodium gluconate in a naphthalene-based high-efficiency water-reducer for large and medium-sized hydropower projects. The method is to use a naphthalene-based high-efficiency water-reducer solution to control the pH of the naphthalene-based high-efficiency water-reducer solution to 8.0 to 12.0 The preparation method of the naphthalene series high-efficiency water reducer solution comprises the following steps:

[0049] Step 1: Use concrete mixing water to clean the water reducing agent preparation pool of the mixing system, and keep the preparation pool in a clean and anhydrous state.

[0050] Step 2: Take 5 parts of industrial grade NaOH and 1 part of industrial grade Na(CO 3 ) 2 Put it into the water reducer preparation pool, gradually pour in about 1 / 4 of the pool volume with concrete mixing water to dissolve, and start the stirring device in the preparation pool at the same time, and continue stirring at a speed of 200 r...

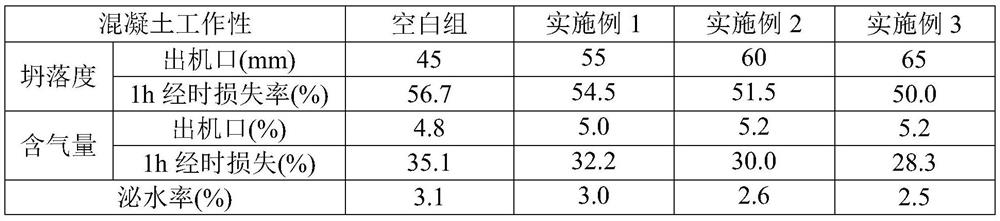

Embodiment 3

[0069] A naphthalene-based superplasticizer solution for large and medium-sized hydropower projects that can inhibit the decomposition of sodium gluconate. The pH of the naphthalene-based superplasticizer solution is controlled to be 8.0 to 12.0; , B, C three components, each component is as follows:

[0070] A component is NaOH, Na(CO 3 ) 2 , B component is naphthalene series superplasticizer powder, C is concrete mixing water. The preparation method of the naphthalene series high-efficiency water reducer solution comprises the following steps:

[0071] Step 1: Use concrete mixing water to clean the water reducing agent preparation pool of the mixing system, and keep the preparation pool in a clean and anhydrous state.

[0072] Step 2: Take 3 parts of industrial grade NaOH and 1 part of industrial grade Na(CO 3 ) 2 Put it into the water reducer preparation pool, gradually pour in about 1 / 4 of the pool volume with concrete mixing water to dissolve, and start the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com